Feeling lost in a sea of interview questions? Landed that dream interview for Armature Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Armature Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

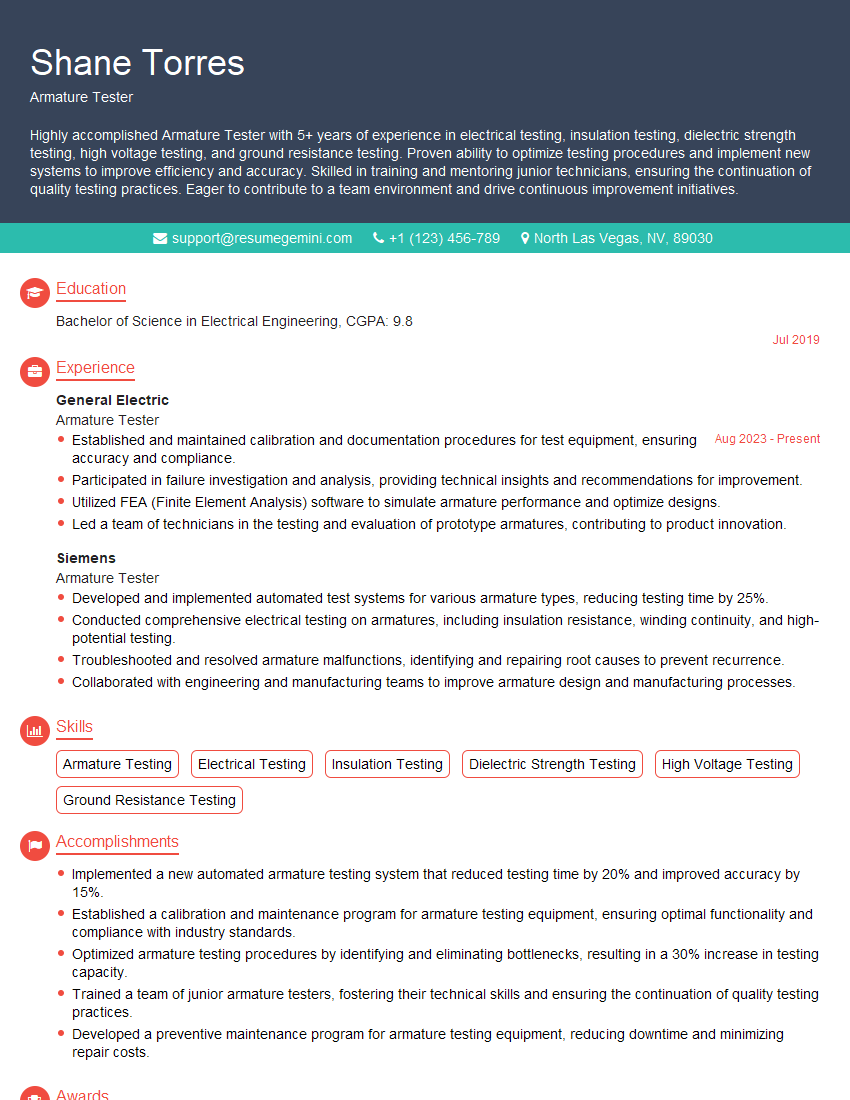

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armature Tester

1. What is the difference between a DC and an AC armature?

Answer:

- DC armature: A DC armature is a type of electric motor armature that is used in direct current (DC) motors. It consists of a coil of wire wound around a laminated iron core. When a DC current is passed through the coil, it creates a magnetic field that interacts with the magnetic field of the stator to produce torque.

- AC armature: An AC armature is a type of electric motor armature that is used in alternating current (AC) motors. It consists of a coil of wire wound around a laminated iron core. When an AC current is passed through the coil, it creates a rotating magnetic field that interacts with the magnetic field of the stator to produce torque.

2. What are the different types of armature windings?

Types of Armature Winding

- Lap winding: In a lap winding, the coils are connected in series and the current flows through each coil in the same direction. This type of winding is used in low-voltage motors.

- Wave winding: In a wave winding, the coils are connected in series and the current flows through each coil in opposite directions. This type of winding is used in high-voltage motors.

Advantages and Disadvantages

- Advantages of lap winding: Simple construction, low cost, and high efficiency.

- Disadvantages of lap winding: Low voltage rating and high ripple current.

- Advantages of wave winding: High voltage rating, low ripple current, and good commutation.

- Disadvantages of wave winding: Complex construction and higher cost.

3. What are the factors that affect the armature resistance?

Answer:

- Length of the armature winding

- Cross-sectional area of the armature winding

- Material of the armature winding

- Temperature of the armature winding

4. What are the different methods of armature testing?

Answer:

- Open-circuit (OC) test: The OC test is used to determine the armature resistance and the induced emf of the armature. The test is performed by applying a DC voltage to the armature terminals and measuring the current and voltage.

- Short-circuit (SC) test: The SC test is used to determine the armature inductance and the armature reactance. The test is performed by short-circuiting the armature terminals and applying a DC voltage to the terminals.

- Load test: The load test is used to determine the armature performance under load. The test is performed by connecting the armature to a load and measuring the current, voltage, and speed of the armature.

5. What are the common faults in an armature?

Answer:

- Open circuit

- Short circuit

- Ground fault

- Armature winding insulation failure

- Commutator bar damage

6. How do you troubleshoot an armature fault?

Answer:

- Open circuit: An open circuit can be detected by measuring the resistance of the armature winding. If the resistance is infinite, then there is an open circuit in the winding.

- Short circuit: A short circuit can be detected by measuring the resistance of the armature winding. If the resistance is very low, then there is a short circuit in the winding.

- Ground fault: A ground fault can be detected by measuring the insulation resistance between the armature winding and the frame of the motor. If the insulation resistance is low, then there is a ground fault.

- Armature winding insulation failure: Armature winding insulation failure can be detected by performing an insulation resistance test. If the insulation resistance is low, then the insulation is failing.

- Commutator bar damage: Commutator bar damage can be detected by visually inspecting the commutator. If the commutator bars are worn or damaged, then the commutator will need to be replaced.

7. What are the safety precautions that should be taken when working on an armature?

Answer:

- Always disconnect the power before working on an armature.

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Be aware of the potential hazards of working with electricity.

- Do not attempt to repair an armature if you are not qualified.

8. What are the latest trends in armature testing?

Answer:

- Computer-aided testing: Computer-aided testing is becoming increasingly common in the armature testing industry. This technology allows for faster and more accurate testing.

- Non-destructive testing: Non-destructive testing is a type of testing that does not damage the armature. This technology is becoming increasingly popular as it allows for the testing of armatures without having to disassemble them.

- Predictive maintenance: Predictive maintenance is a type of maintenance that uses data to predict when an armature is likely to fail. This technology can help to prevent unplanned downtime and costly repairs.

9. What are the challenges facing the armature testing industry?

Answer:

- The increasing complexity of armatures: Armatures are becoming increasingly complex, which is making it more difficult to test them accurately.

- The need for faster and more efficient testing: The demand for faster and more efficient testing is increasing as manufacturers strive to reduce downtime and improve productivity.

- The need for more reliable testing: The need for more reliable testing is increasing as manufacturers strive to improve the quality of their products.

10. What are the opportunities for growth in the armature testing industry?

Answer:

- The growing demand for electric motors: The growing demand for electric motors is creating a corresponding demand for armature testing services.

- The increasing adoption of predictive maintenance: The increasing adoption of predictive maintenance is creating a new market for armature testing services.

- The development of new technologies: The development of new technologies, such as computer-aided testing and non-destructive testing, is creating new opportunities for growth in the armature testing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armature Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armature Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Armature Testers are skilled technicians responsible for measuring, evaluating, and diagnosing the performance of electric motors and their components, particularly the armatures, which are the rotating parts of the motors. They ensure the proper functioning, reliability, and safety of these motors in various industrial settings.

1. Testing and Evaluation

Utilize specialized testing equipment and procedures to conduct comprehensive tests on armatures, including insulation resistance, winding resistance, inter-winding resistance, and other performance evaluations.

2. Fault Diagnosis and Troubleshooting

Analyze test results and identify defects, such as shorts, grounds, open circuits, and mechanical issues within the armature. Determine the root cause of these failures and recommend appropriate corrective actions.

3. Repair and Maintenance

Perform necessary repairs and maintenance on armatures, such as cleaning, replacing faulty components, or rewinding damaged windings, to restore their functionality and performance.

4. Quality Control

Adhere to established quality standards and specifications during testing and repair processes. Maintain accurate records and documentation of test results and repair procedures.

Interview Tips

Preparing thoroughly for an Armature Tester interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Research the company you are applying to, their industry, and the specific requirements of the Armature Tester role within that context.

- Understand their products, services, and market position.

- Learn about the latest industry trends and advancements in armature testing.

2. Highlight Your Technical Skills

Emphasize your expertise in armature testing techniques and equipment. Quantify your experience and provide specific examples of your testing and troubleshooting abilities.

- Discuss your experience with different types of electric motors and armatures.

- Mention any certifications or training you have received in armature testing.

3. Showcase Your Problem-Solving Abilities

Armature Testers are often required to solve complex technical problems. Provide examples from your previous experience where you successfully diagnosed and resolved armature issues.

- Describe a situation where you identified an obscure fault and developed an innovative solution.

- Explain how you troubleshoot and repair armatures to meet performance specifications.

4. Emphasize Your Attention to Detail and Accuracy

Accuracy is crucial in armature testing. Highlight your meticulous approach to testing procedures and your ability to follow instructions carefully.

- Mention your experience in maintaining accurate records and documentation.

- Explain how you ensure the reliability and validity of your test results.

5. Prepare for Common Interview Questions

Research common interview questions for Armature Testers and prepare your answers accordingly. Practice answering these questions concisely and professionally.

- Tell me about your experience in armature testing.

- Describe a time when you faced a challenging armature issue and how you resolved it.

- Why are you interested in working as an Armature Tester for our company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Armature Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.