Feeling lost in a sea of interview questions? Landed that dream interview for Armature Winder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Armature Winder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

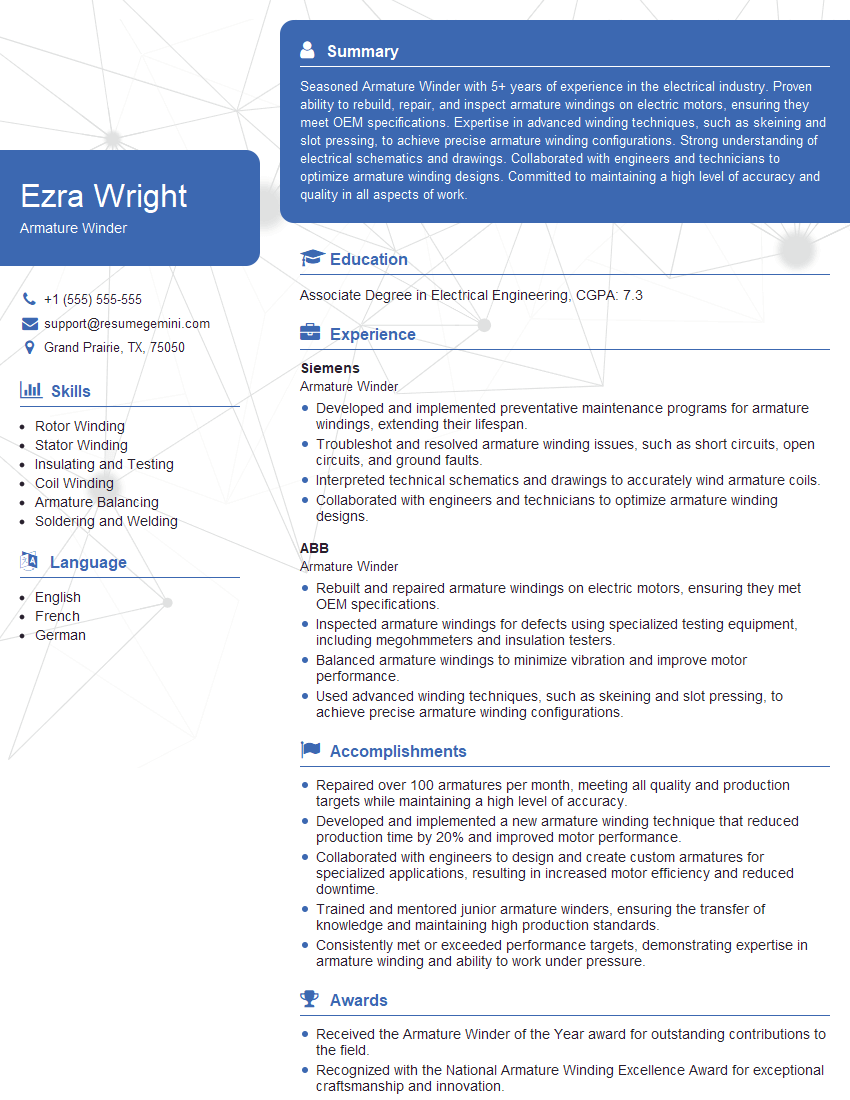

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armature Winder

1. What is the difference between lap and wave winding?

Answer:

- Lap Winding: In lap winding, the coils are connected in series and the current flows through all the coils in the same direction.

- Wave Winding: In wave winding, the coils are connected in parallel and the current flows through the coils in opposite directions.

2. What are the different types of armature windings?

Answer:

Types of Armature Windings:

- Lap Winding

- Wave Winding

- Consequent-pole Winding

Subdivisions of Armature Windings:

- Simplex Winding

- Duplex Winding

- Triplex Winding

- Quadruplex Winding

3. What is the purpose of a commutator?

Answer:

- To reverse the direction of current flow in the armature coils as the armature rotates.

- To maintain a unidirectional current flow in the external circuit.

4. What are the factors that affect the efficiency of an armature winding?

Answer:

- Number of slots

- Number of conductors

- Type of winding

- Magnetic field strength

5. What are the steps involved in winding an armature?

Answer:

- Prepare the armature core

- Insert the coils into the slots

- Connect the coils in series or parallel

- Solder the connections

- Insulate the windings

6. What are the different methods of testing armature windings?

Answer:

- Growler test

- Megger test

- Hipot test

7. What are the causes of armature winding failures?

Answer:

- Overheating

- Mechanical damage

- Electrical insulation breakdown

8. What are the safety precautions that should be taken when working with armature windings?

Answer:

- Wear proper safety gear

- Use insulated tools

- Disconnect the power source before working on the winding

9. What are the advantages and disadvantages of hand winding vs. machine winding armature windings?

Answer:

Advantages of Hand Winding:

- Greater flexibility in design

- Lower initial investment cost

Disadvantages of Hand Winding:

- Slower production rate

- Greater potential for human error

Advantages of Machine Winding:

- Faster production rate

- Higher precision and consistency

Disadvantages of Machine Winding:

- Higher initial investment cost

- Less flexibility in design

10. What are the latest trends in armature winding technology?

Answer:

- Automated winding machines

- Advanced insulating materials

- Design optimization software

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armature Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armature Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Armature winders are essential to the manufacturing and repair of electrical motors and generators. Their work requires precision and attention to detail to ensure that the motors and generators operate efficiently and reliably.

1. Winding Armatures

Armature winders use specialized equipment to wind coils of wire around the armature of an electric motor or generator. The coils must be wound evenly and tightly to create a strong magnetic field and ensure proper operation of the motor or generator.

2. Inspecting and Testing

After winding the armature, armature winders inspect and test it to ensure that it meets specifications. They check for continuity, insulation resistance, and other factors to verify that the armature is free of defects and will perform as intended.

3. Troubleshooting and Repair

Armature winders also troubleshoot and repair faulty motors and generators. They identify the source of the problem and make the necessary repairs to restore the equipment to working order.

4. Maintenance

Armature winders perform regular maintenance on motors and generators to prevent problems from occurring. They clean and lubricate the equipment, inspect for signs of wear or damage, and make minor adjustments as needed.

Interview Tips

Preparing for an armature winder interview requires understanding the role’s responsibilities and highlighting your relevant skills and experience. Here are some tips to help you ace your interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re seeking. This will help you understand their business, culture, and the specific requirements of the role.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples of your skills and experience.

3. Highlight Your Relevant Skills

Emphasize your proficiency in armature winding techniques, including coil winding, insulation, and testing. Showcase your understanding of electrical principles and your ability to troubleshoot and repair electrical equipment.

4. Demonstrate Your Attention to Detail

Armature winding requires meticulous attention to detail. Highlight your ability to work precisely and follow instructions carefully. Provide examples of your quality control measures and your commitment to delivering high-quality work.

5. Show Your Troubleshooting Abilities

Interviewers will be interested in your problem-solving skills. Share examples of how you have identified and resolved issues with electrical equipment. Explain your approach to troubleshooting and your ability to find practical solutions.

6. Be Enthusiastic and Professional

Convey your enthusiasm for armature winding and your commitment to the field. Demonstrate your professionalism and eagerness to learn and contribute to the company. A positive attitude and willingness to go the extra mile will make a lasting impression on the interviewer.

Next Step:

Now that you’re armed with the knowledge of Armature Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Armature Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini