Feeling lost in a sea of interview questions? Landed that dream interview for Armoring Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Armoring Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

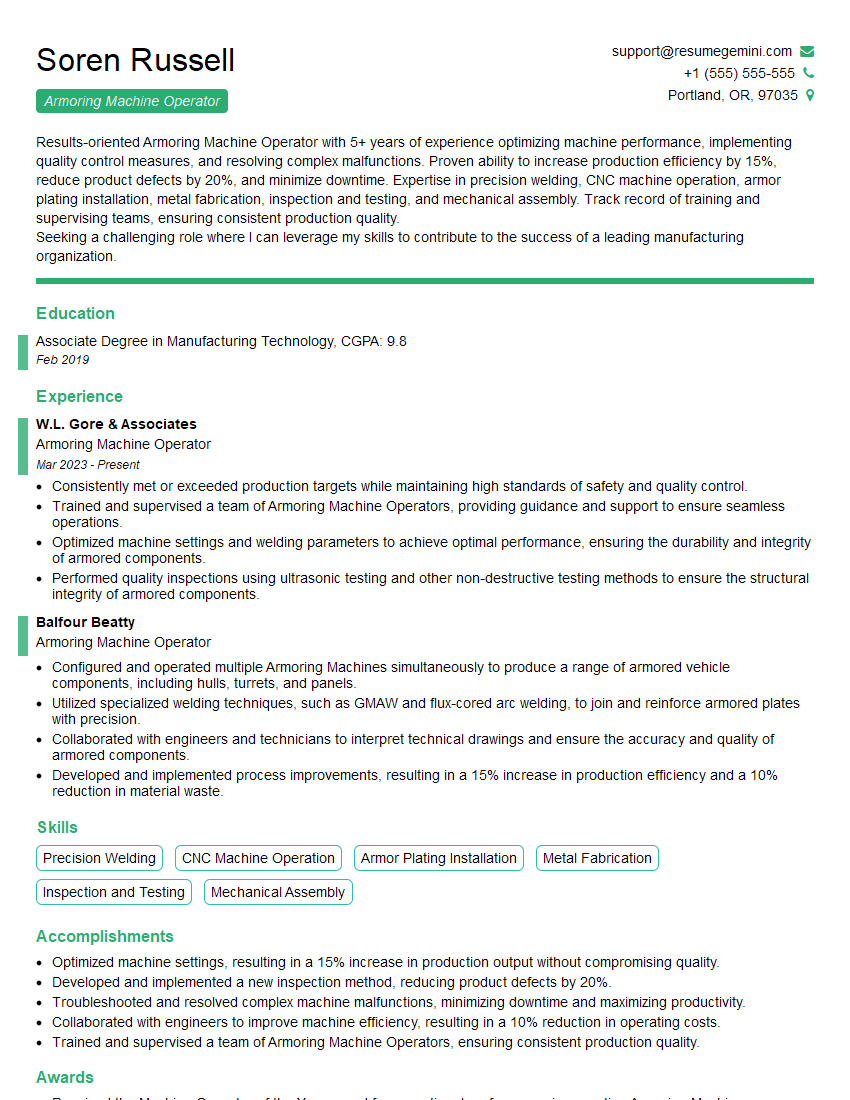

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armoring Machine Operator

1. What are the various types of armoring materials that can be used, and which is most suitable for different applications?

Answer: There are several types of armoring materials available, each with its own unique properties and applications. Some of the most common types include:

- Steel: Steel is a strong and durable material that provides excellent protection against ballistic threats. It is commonly used in armored vehicles, safes, and body armor.

- Aluminum: Aluminum is lighter and less expensive than steel, but it is also less strong and durable. It is often used in armored vehicles and aircraft because of its weight-saving advantages.

- Composite materials: Composite materials are made from a combination of different materials, such as fiberglass, carbon fiber, and ceramic. They are lightweight and strong, and they offer excellent protection against ballistic and explosive threats.

2. What are the key factors to consider when selecting an armoring material?

- Threat level: The type of threat that the armoring will be protecting against is a key factor to consider. Different materials offer different levels of protection against different types of threats.

- Weight: The weight of the armoring material is important to consider, especially in applications where weight is a concern, such as in armored vehicles and aircraft.

- Cost: The cost of the armoring material is also an important factor to consider.

3. What are the different techniques used for applying armoring?

- Welding: Welding is a process of joining two pieces of metal by melting them together. It is commonly used to apply armoring to vehicles and safes.

- Bolting: Bolting is a process of joining two pieces of metal using bolts and nuts. It is commonly used to apply armoring to buildings and structures.

- Adhesive bonding: Adhesive bonding is a process of joining two pieces of material using an adhesive. It is commonly used to apply armoring to composite materials.

4. What are the quality control procedures that must be followed during the armoring process?

Answer: To ensure the quality and effectiveness of the armoring, several quality control procedures must be followed during the process, including:

- Material inspection: The armoring material should be inspected before use to ensure that it meets the required specifications.

- Process control: The armoring process should be controlled to ensure that it is carried out in accordance with the established procedures.

- Testing: The armored product should be tested to ensure that it meets the required performance standards.

5. What are the common problems that can occur during the armoring process and how can they be prevented?

- Material defects: Material defects, such as cracks or voids, can weaken the armoring and reduce its effectiveness. These defects can be prevented by using high-quality materials and by following proper inspection procedures.

- Process errors: Process errors, such as improper welding or bonding, can also weaken the armoring. These errors can be prevented by following proper procedures and by using qualified personnel.

- Environmental factors: Environmental factors, such as extreme temperatures or moisture, can also affect the performance of the armoring. These factors can be mitigated by using appropriate materials and by taking measures to protect the armoring from the elements.

6. What are the different types of equipment used in the armoring process?

- Welding equipment: Welding equipment is used to join pieces of metal together. It includes welding machines, welding rods, and welding helmets.

- Bolting equipment: Bolting equipment is used to join pieces of metal together using bolts and nuts. It includes drills, wrenches, and torque wrenches.

- Adhesive bonding equipment: Adhesive bonding equipment is used to join pieces of material together using an adhesive. It includes adhesive applicators, mixing guns, and curing ovens.

7. What are the safety precautions that must be followed when working with armoring materials and equipment?

Answer: To ensure the safety of personnel and the quality of the work, several safety precautions must be followed when working with armoring materials and equipment, including:

- Wear appropriate protective gear: When working with armoring materials and equipment, it is important to wear appropriate protective gear, such as safety glasses, gloves, and a hard hat.

- Follow proper procedures: It is important to follow proper procedures when working with armoring materials and equipment. This includes following the manufacturer’s instructions and using the equipment correctly.

- Be aware of the hazards: It is important to be aware of the hazards associated with working with armoring materials and equipment. These hazards include electrical hazards, fire hazards, and chemical hazards.

8. What are the maintenance and storage requirements for armoring equipment?

Answer: To ensure the longevity and effectiveness of armoring equipment, it is important to follow proper maintenance and storage requirements. This includes:

- Regular inspection: Regularly inspecting the equipment for any damage or wear and tear.

- Cleaning: Cleaning the equipment regularly to remove any dirt or debris.

- Lubrication: Lubricating the equipment regularly to ensure smooth operation.

- Proper storage: Storing the equipment in a dry and secure location when not in use.

9. What are the industry standards and regulations that apply to the armoring industry?

Answer: To ensure the quality and safety of armoring products and services, several industry standards and regulations apply to the armoring industry, including:

- International Standards Organization (ISO): ISO is a global organization that develops and publishes international standards for various industries, including the armoring industry.

- American National Standards Institute (ANSI): ANSI is a national organization that develops and publishes American national standards for various industries, including the armoring industry.

- National Institute of Justice (NIJ): NIJ is a United States federal agency that develops and publishes standards for law enforcement equipment, including armoring.

10. What are the career advancement opportunities for an Armoring Machine Operator?

Answer: Armoring Machine Operators with experience and expertise can advance their careers in various ways, including:

- Supervisor: Supervising a team of Armoring Machine Operators and managing the armoring process.

- Quality Control Inspector: Inspecting armored products for quality and compliance with industry standards.

- Design Engineer: Designing and developing new armoring products and solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armoring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armoring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Armoring Machine Operator is responsible for operating and maintaining armoring machines used to create armored vehicles. This role requires a combination of technical skills, attention to detail, and safety consciousness. Key job responsibilities include:

1. Machine Operation

Operate armoring machines to cut, shape, and weld armor plates.

- Set up and calibrate machines according to specifications.

- Inspect and maintain equipment to ensure optimal performance.

2. Armor Installation

Install armor plates onto vehicles following blueprints and design specifications.

- Read and interpret technical drawings and instructions.

- Apply welding techniques to secure armor plates securely.

3. Quality Control

Conduct quality inspections on armor installations to ensure compliance with standards.

- Examine joints for proper welding and alignment.

- Test armor integrity using specialized equipment.

4. Safety and Maintenance

Adhere to safety protocols and maintain a clean and organized work area.

- Wear appropriate safety gear and follow safety procedures.

- Perform routine maintenance on machinery to prevent breakdowns.

Interview Tips

Preparing thoroughly for an Armoring Machine Operator interview can boost your chances of success. Here are some tips to help you ace it:

1. Research the Company and Position

Gather information about the company’s background, industry, and the specific requirements of the Armoring Machine Operator role. This knowledge will help you understand the company’s needs and tailor your answers accordingly.

2. Practice Your Skills

Before the interview, practice operating armoring machines and demonstrating your welding techniques. This not only sharpens your skills but also builds your confidence in showcasing them during the interview.

3. Highlight Your Experience

Emphasize your relevant experience and skills in armoring operations. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities. For instance, mention the number of armored vehicles you have worked on or the quality standards you have consistently met.

4. Show Your Safety Consciousness

Stress your commitment to safety in your work. Describe your experience in following safety protocols and maintaining a clean and organized work area. This shows that you value safety and are mindful of potential hazards.

5. Ask Questions

At the end of the interview, ask thoughtful questions about the company, the position, and the industry. This demonstrates your interest and engagement, and it also allows you to gather additional information that can help you make an informed decision.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Armoring Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Armoring Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.