Are you gearing up for an interview for a Artificial Leather Calender Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Artificial Leather Calender Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

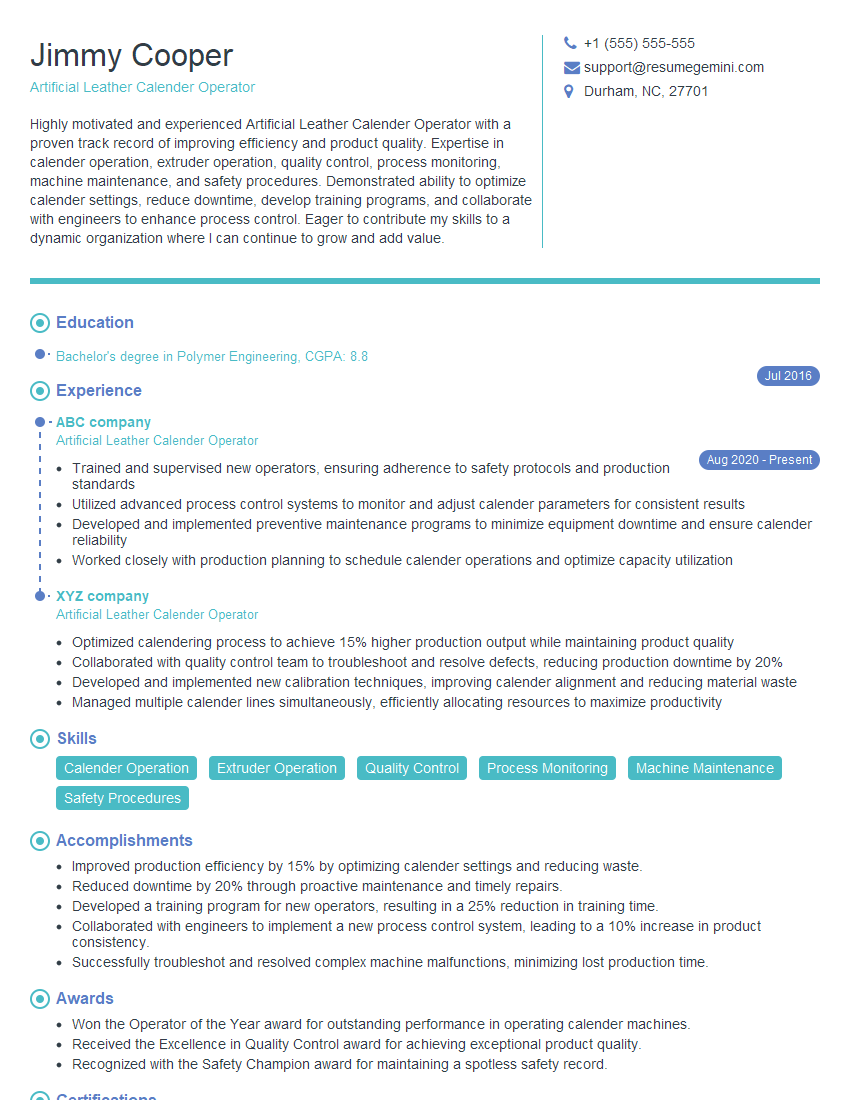

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Artificial Leather Calender Operator

1. Describe the process of calendering artificial leather.

- Artificial leather is passed through nip rolls under high pressure and temperature.

- Rolls work to emboss grains, texture, and patterns onto the leather.

- Process improves the leather’s surface finish, physical properties, and durability.

2. What are the key parameters to control during the calendering process?

Temperature

- Controls the plasticity of the leather.

- Too high: damages leather; too low: poor calendering.

Pressure

- Determines the depth of embossing and leather compaction.

- Too high: crushes leather; too low: insufficient pattern transfer.

Roll speed

- Affects the thickness and grain pattern of the leather.

- Too fast: thin leather with poor grain; too slow: thick leather with excessive grain.

3. What are the common defects encountered during calendering and how do you resolve them?

- Wrinkles: Adjust roll alignment and increase tension.

- Bubbles: Use a vacuum system to remove air from the leather.

- Cracking: Reduce calendering temperature or adjust pressure.

- Uneven surface: Clean or replace worn rolls, check roll alignment.

4. How do you ensure consistency in the quality of calendered leather?

- Establish and follow SOPs for all calendering processes.

- Regularly calibrate and maintain calendering equipment.

- Monitor and record key process parameters (temperature, pressure, speed).

- Inspect leather samples for defects and make necessary adjustments.

5. Describe the safety precautions you observe when operating a calendering machine.

- Wear appropriate safety gear (gloves, eye protection, earplugs).

- Inspect machine before use and ensure all guards are in place.

- Never reach into the calender nip point with hands or tools.

- Follow lockout/tagout procedures when servicing the machine.

6. How do you troubleshoot common equipment failures on a calendering machine?

- Roll breakage: Check roll alignment and bearings, replace if necessary.

- Hydraulic leaks: Inspect hoses and fittings, replace or tighten as needed.

- Electrical problems: Check wiring, switches, and fuses.

- Temperature control issues: Check thermostat and thermocouple.

7. Explain how you would optimize the calendering process to improve efficiency and reduce waste.

- Analyze current processes to identify bottlenecks and inefficiencies.

- Investigate new technologies and techniques to increase productivity.

- Implement lean manufacturing principles to reduce waste and improve flow.

- Train operators on best practices to minimize errors and rework.

8. What are the latest advancements in artificial leather calendering technology?

- Automated calendering machines with computer controls.

- Laser engraving for precise pattern transfer.

- Use of eco-friendly materials and processes.

- Development of new artificial leather formulations with improved properties.

9. How do you stay up-to-date with the latest industry trends and best practices in artificial leather calendering?

- Attend industry conferences and webinars.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Seek training and certification opportunities.

10. Why are you interested in working as an Artificial Leather Calender Operator?

I am passionate about the manufacturing process and have a proven track record in operating calendering machines efficiently and effectively. I am eager to contribute my skills and knowledge to your team and help achieve your production goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Artificial Leather Calender Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Artificial Leather Calender Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Artificial Leather Calender Operators work in manufacturing plants that produce artificial leather. They are responsible for operating and maintaining the calender machines used in the production of this material. Calendering is a process of applying heat and pressure to multiple layers of material to bond them together and impart a desired finish.

1. Machine Operation

Operate and maintain artificial leather calender machines, ensuring optimal performance.

- Control machine settings, such as temperature, pressure, and speed.

- Monitor machine processes to identify and correct any deviations.

- Conduct routine maintenance and troubleshoot any machine malfunctions.

2. Material Handling

Load and unload raw materials and finished products from the calender machine.

- Inspect materials for defects and ensure they meet quality standards.

- Handle and store materials safely and efficiently.

- Dispose of waste materials responsibly.

3. Quality Control

Monitor and ensure the quality of artificial leather produced.

- Perform quality checks throughout the production process.

- Identify and correct any defects in the finished product.

4. Safety and Environment

Maintain a safe and clean work environment.

- Follow established safety procedures and wear appropriate safety gear.

- Maintain a clean and organized work area.

- Dispose of hazardous materials properly.

Interview Tips

To ace the interview for an Artificial Leather Calender Operator position, it is important to prepare thoroughly and showcase your relevant skills and experience.

1. Research the Company and Industry

Familiarize yourself with the company you are applying to, its products, and its position in the artificial leather industry. This demonstrates your interest and knowledge of the field.

- Visit the company website to learn about their history, mission, and products.

- Research industry trends and technological advancements in artificial leather manufacturing.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining calender machines, as well as your knowledge of artificial leather production processes. Quantify your accomplishments whenever possible.

- Describe your previous role in detail, including your responsibilities and achievements.

- Use specific examples to demonstrate your skills in machine operation, material handling, and quality control.

3. Prepare for Technical Questions

Be prepared to answer technical questions about artificial leather calendering processes, machine maintenance, and quality control procedures. Practice answering these questions clearly and concisely.

- Review common calendering techniques and troubleshooting methods.

- Familiarize yourself with industry standards and quality control measures.

4. Emphasize Safety and Environmental Awareness

Highlight your commitment to safety and environmental responsibility. Explain your understanding of safety procedures and hazardous material handling.

- Describe your experience with safety protocols in a manufacturing setting.

- Explain your knowledge of waste disposal and environmental regulations.

5. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to these questions to deliver clear and well-thought-out responses.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Be enthusiastic and confident in your responses.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Artificial Leather Calender Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!