Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Asbestos Brake Lining Finisher Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

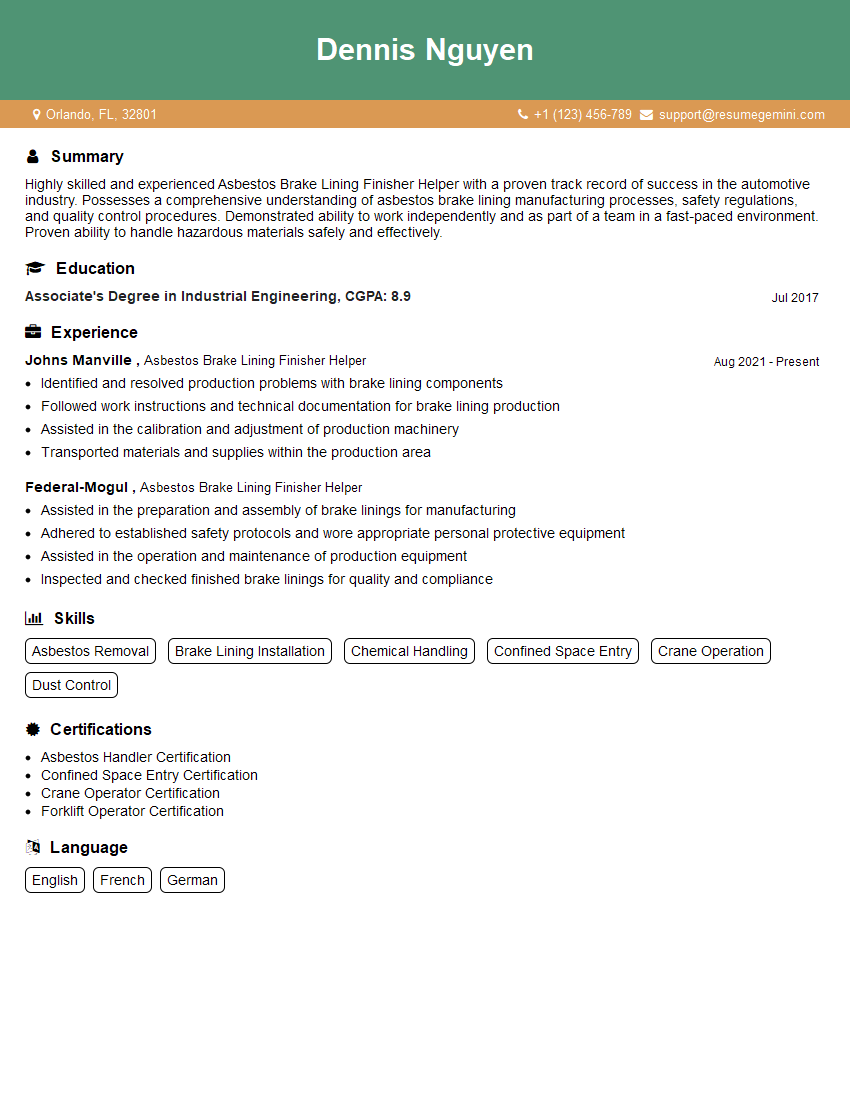

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asbestos Brake Lining Finisher Helper

1. What are the key responsibilities of an Asbestos Brake Lining Finisher Helper?

As an Asbestos Brake Lining Finisher Helper, my primary responsibilities include:

- Assisting the Finisher in the production of asbestos brake linings

- Mixing and preparing raw materials according to specified formulas

- Operating and maintaining equipment used in the production process

- Inspecting finished products for quality and conformance to specifications

- Maintaining a clean and organized work area

2. Describe the different types of asbestos brake linings available.

Woven Brake Linings

- Constructed from asbestos fibers woven into a fabric

- Durable and wear-resistant

- Suitable for heavy-duty applications

Molded Brake Linings

- Made by mixing asbestos fibers with resins and other materials

- Molded into specific shapes and sizes

- Provide high friction and durability

Sintered Brake Linings

- Formed by heating and pressing asbestos fibers and other materials

- Extremely dense and durable

- Used in high-performance and racing applications

3. What are the safety precautions that must be followed when working with asbestos?

To ensure safety, I strictly adhere to the following precautions when working with asbestos:

- Wearing appropriate personal protective equipment (PPE) including respirators, gloves, and coveralls

- Working in well-ventilated areas

- Minimizing dust generation and exposure

- Following proper disposal and handling procedures

- Regularly monitoring air quality and maintaining a clean work environment

4. How do you measure the thickness of a brake lining?

To accurately measure the thickness of a brake lining, I use a micrometer or a caliper:

- Ensure the measuring tool is calibrated and in good condition

- Position the tool perpendicular to the lining surface

- Apply gentle pressure and record the measurement

- Take multiple measurements at different points to obtain an average thickness

5. What factors can affect the performance of an asbestos brake lining?

The performance of an asbestos brake lining can be influenced by several factors:

- Friction coefficient: Determines the amount of friction generated between the lining and the brake drum or rotor

- Wear resistance: Measures how well the lining withstands wear and tear over time

- Heat resistance: Indicates the lining’s ability to dissipate heat generated during braking

- Noise generation: Some linings may produce more noise than others during braking

- Environmental conditions: Factors such as temperature, humidity, and contaminants can affect lining performance

6. How do you troubleshoot common problems that occur with asbestos brake linings?

When troubleshooting common problems with asbestos brake linings, I follow these steps:

- Identify the issue: Determine the specific symptoms or performance problems being experienced

- Inspect the lining: Examine the lining for signs of wear, damage, or contamination

- Check the brake system: Inspect other components of the brake system, such as the calipers, rotors, or drums, for issues

- Consult with a qualified mechanic or manufacturer: Seek professional advice if necessary to diagnose and resolve complex problems

7. What are the different methods used to apply asbestos brake linings?

Asbestos brake linings can be applied using various methods:

- Mechanical bonding: Linings are attached to brake shoes or pads using rivets, bolts, or adhesives

- Chemical bonding: Linings are bonded to the backing material using resins or adhesives

- Sintering: Linings are heated and pressed to form a strong bond with the backing material

8. How do you ensure that asbestos brake linings meet quality standards?

To ensure quality, I follow these steps:

- Inspect raw materials: Verify that the asbestos fibers and other components meet specifications

- Monitor the production process: Ensure that all procedures are followed correctly and equipment is properly calibrated

- Perform quality control checks: Conduct regular inspections and tests to assess the thickness, density, and performance of finished linings

- Maintain records: Document all quality control checks and any corrective actions taken

9. How do you handle and dispose of asbestos waste safely?

Asbestos waste must be handled and disposed of with extreme care:

- Wear appropriate PPE: Use respirators, gloves, and other protective gear

- Minimize dust generation: Keep waste wet or enclosed to prevent fibers from becoming airborne

- Follow disposal regulations: Dispose of waste in accordance with local, state, and federal regulations

- Train employees: Ensure that all personnel involved in handling asbestos waste are properly trained

10. How do you stay up-to-date with industry best practices for working with asbestos brake linings?

I stay informed about industry best practices through the following methods:

- Attend conferences and workshops: Participate in industry events to learn about new technologies and regulations

- Read trade publications: Regularly review industry magazines and journals for updates on safety procedures and product advancements

- Consult with experts: Seek guidance from experienced professionals or manufacturers to stay abreast of best practices

- Participate in training programs: Enroll in training courses to enhance my knowledge and skills in asbestos handling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asbestos Brake Lining Finisher Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asbestos Brake Lining Finisher Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Asbestos Brake Lining Finisher Helper, you will play a crucial role in the production of asbestos brake linings, ensuring efficient and high-quality manufacturing processes.

1. Fabrication Process Assistance

You will actively assist in the fabrication of brake linings, performing tasks such as:

- Loading and unloading raw materials, including asbestos fibers and binding agents

- Operating machinery to mix and shape the lining material

- Monitoring the production process and making adjustments as needed

2. Quality Control and Inspection

You will be responsible for maintaining quality standards by performing:

- Visual inspections of finished linings for defects and imperfections

- Dimensional measurements to ensure compliance with specifications

- Testing the linings for strength and durability

3. Equipment Maintenance and Repair

You will contribute to maintaining a safe and efficient work environment by:

- Performing basic maintenance and repairs on equipment used in the production process

- Reporting any malfunctions or safety hazards to supervisors

- Following established safety protocols and adhering to asbestos handling regulations

4. Housekeeping and Material Handling

To ensure a clean and organized work area, you will be responsible for:

- Maintaining a clean and safe work environment

- Proper handling and storage of materials, including asbestos and binding agents

- Following waste disposal procedures for asbestos-containing materials

Interview Tips

To ace the interview for an Asbestos Brake Lining Finisher Helper position, preparation is key. Here are some essential tips and tricks to help you stand out as a qualified candidate:

1. Research the Company and Position

Take the time to learn about the company, its industry, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the position and show that you have taken the interview process seriously.

2. Highlight Relevant Experience and Skills

In your resume and during the interview, be sure to highlight any previous experience or skills that are relevant to the job responsibilities of an Asbestos Brake Lining Finisher Helper. If you have worked in a manufacturing or production environment, or possess knowledge of asbestos handling protocols, make sure to emphasize these qualifications.

3. Prepare for Technical Questions

As the position involves technical aspects, you may encounter questions related to the production process, quality control, or equipment maintenance. Familiarize yourself with the basic principles of these areas and be prepared to demonstrate your understanding of the job’s technical requirements.

4. Emphasize Safety and Attention to Detail

Safety is paramount in this role, so during the interview, highlight your commitment to following safety protocols and handling asbestos materials responsibly. Additionally, demonstrate your attention to detail by providing examples of your ability to perform precise measurements and identify defects during quality inspections.

5. Ask Thoughtful Questions

Towards the end of the interview, prepare a few thoughtful questions for the interviewer. This will show your genuine interest in the position and allow you to clarify any aspects of the job or company that you are curious about.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Asbestos Brake Lining Finisher Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.