Are you gearing up for an interview for a Asbestos Brake Lining Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Asbestos Brake Lining Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

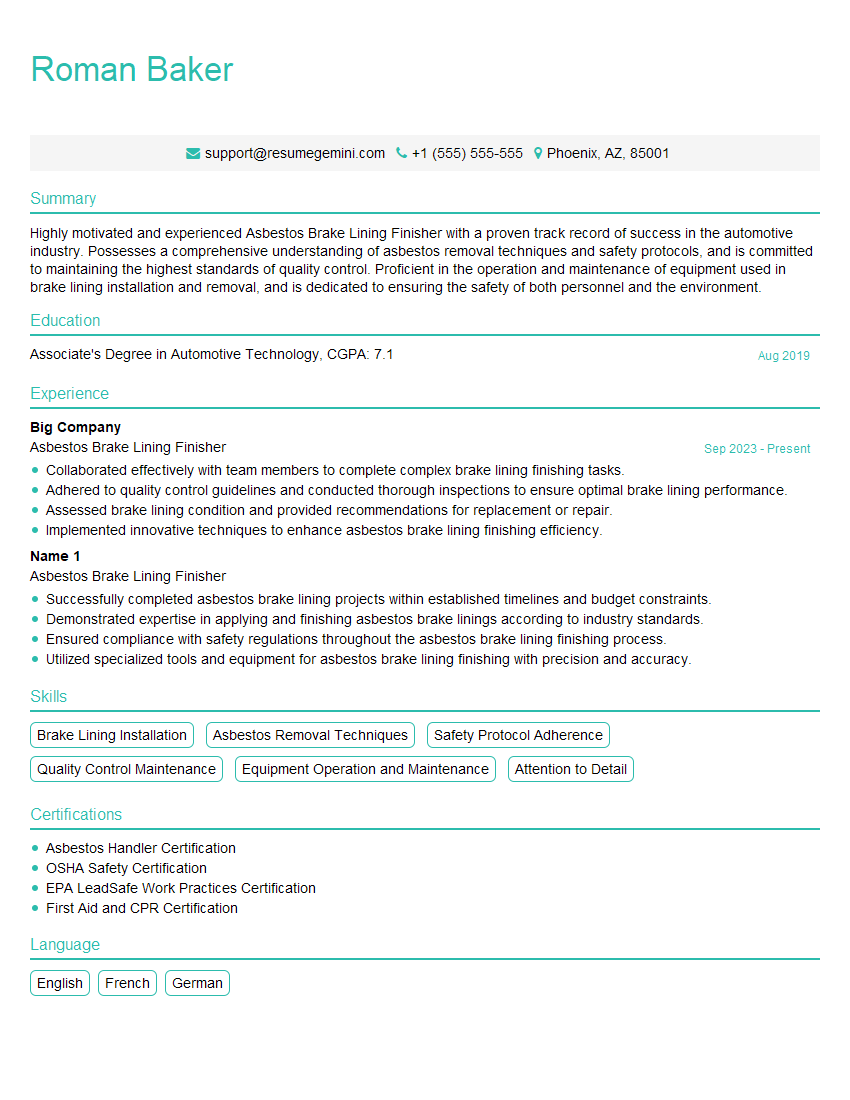

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asbestos Brake Lining Finisher

1. Describe the process of preparing the mold for asbestos brake lining production

The mold preparation process involves:

- Cleaning the mold to remove any debris or contaminants

- Lubricating the mold to prevent the lining from sticking

- Installing the mold insert, which determines the shape of the lining

- Clamping the mold together to secure the insert and create a sealed cavity for the lining material

2. How do you ensure the proper mixing and application of asbestos fibers and other materials in the lining?

Quality Control Measures

- Using precise measuring equipment to ensure accurate proportions

- Conducting regular quality checks on the materials to verify their composition and consistency

Application Techniques

- Using specialized machinery to distribute the materials evenly throughout the mold

- Applying the materials in layers to achieve the desired thickness and density

3. Explain the curing process for asbestos brake linings

The curing process ensures the proper bonding and hardening of the lining material:

- Heating the mold at a controlled temperature to initiate the chemical reactions

- Maintaining the temperature for a specific duration to allow the lining to reach its optimal strength and durability

- Cooling the mold gradually to minimize thermal stress and prevent cracking

4. What are the safety precautions you take when working with asbestos materials?

I strictly adhere to all safety protocols, including:

- Wearing appropriate protective gear, such as respirators, gloves, and coveralls

- Working in well-ventilated areas to minimize exposure to airborne fibers

- Following proper disposal procedures to prevent contamination and potential health hazards

5. How do you maintain and calibrate the equipment used in asbestos brake lining production?

I ensure the equipment is in optimal condition through:

- Regular cleaning and lubrication to prevent wear and tear

- Calibrating equipment using calibrated tools to ensure accuracy in measurements and process parameters

- Performing preventive maintenance to identify and address potential issues before they become major problems

6. What troubleshooting techniques do you use to resolve issues that may arise during the production process?

When troubleshooting, I follow a systematic approach:

- Identifying the problem and potential causes

- Analyzing the data and observations to determine the root cause

- Implementing corrective actions and verifying the effectiveness of the solution

- Documenting the troubleshooting process and findings for future reference

7. Explain the importance of quality control in asbestos brake lining production

Quality control is crucial for ensuring:

- Safety: Meeting stringent safety standards to protect users and the environment

- Performance: Delivering reliable performance and durability in various operating conditions

- Customer satisfaction: Exceeding customer expectations and building trust

8. What quality control tests do you perform on finished asbestos brake linings?

I conduct various tests, including:

- Dimensional inspections to verify shape and size specifications

- Strength tests to assess the lining’s ability to withstand friction and wear

- Composition analysis to ensure compliance with material specifications

- Performance tests to evaluate friction characteristics and temperature stability

9. How do you stay up-to-date with industry best practices and advancements in asbestos brake lining production?

I continuously seek knowledge through:

- Attending industry conferences and workshops

- Reading technical publications and journals

- Collaborating with industry experts and peers

- Participating in training programs to enhance skills and stay abreast of new techniques

10. What are your career aspirations within the asbestos brake lining industry?

My career aspirations include:

- Specializing in a particular aspect of production, such as quality control or process optimization

- Supervising or managing a team of asbestos brake lining finishers

- Contributing to research and development efforts to improve lining materials and production techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asbestos Brake Lining Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asbestos Brake Lining Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Asbestos Brake Lining Finisher is responsible for the preparation and finishing of asbestos brake linings used in various brake systems.

1. Preparation of Materials

A Finisher’s key responsibility is to prepare raw materials for brake lining production. This includes mixing and preparing asbestos fibers, resins, and other components according to specified formulations.

- Weigh and measure raw materials accurately to ensure proper ratios in the final product.

- Operate mixing machines to blend materials thoroughly, achieving uniform consistency.

2. Molding and Pressing

The prepared mixture is then molded into brake lining shapes using specialized presses. The Finisher is responsible for:

- Setting up and operating molding machines to shape the brake linings to precise specifications.

- Monitoring pressure and temperature during the pressing process to ensure proper bonding and curing.

3. Finishing and Inspection

Once the brake linings are molded, they undergo finishing processes to ensure their quality and performance.

- Trimming and grinding the linings to remove excess material and achieve desired dimensions.

- Inspecting the finished linings for defects, ensuring they meet quality standards and specifications.

4. Equipment Maintenance

The Finisher is also responsible for maintaining and cleaning the machines and equipment used in the production process.

- Performing regular inspections and maintenance on mixing machines, presses, and other equipment.

- Identifying and troubleshooting any issues or malfunctions, ensuring smooth production flow.

Interview Tips

Interview preparation is crucial for success. Here are some tips to help you ace your interview for an Asbestos Brake Lining Finisher position:

1. Research the Company and Position

Learn about the company’s history, products, and values. Research the specific requirements of the Finisher role and how your skills align with them.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about current trends and technologies.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your responses. Anticipate questions related to your technical skills, experience, and ability to work in a production environment.

- Use the STAR method to structure your answers (Situation, Task, Action, Result).

- Provide specific examples that demonstrate your abilities and accomplishments.

3. Highlight Your Skills and Experience

Emphasize your skills in mixing, molding, and finishing brake linings. Highlight your experience in handling asbestos materials and adhering to safety regulations.

- Quantify your accomplishments with metrics whenever possible.

- Use keywords from the job description in your responses.

4. Demonstrate Your Safety Awareness

Asbestos handling requires strict adherence to safety protocols. In the interview, demonstrate your knowledge of asbestos hazards and your commitment to following safety procedures.

- Explain your experience with personal protective equipment (PPE).

- Discuss your understanding of proper ventilation and waste disposal methods.

5. Ask Questions

Show your interest and engagement by asking thoughtful questions about the company, the position, and the industry. This also gives you an opportunity to clarify any details or address any concerns.

- Ask about the company’s commitment to safety and training.

- Inquire about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with the knowledge of Asbestos Brake Lining Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Asbestos Brake Lining Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini