Are you gearing up for a career in Asbestos-Cement Sheet Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Asbestos-Cement Sheet Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

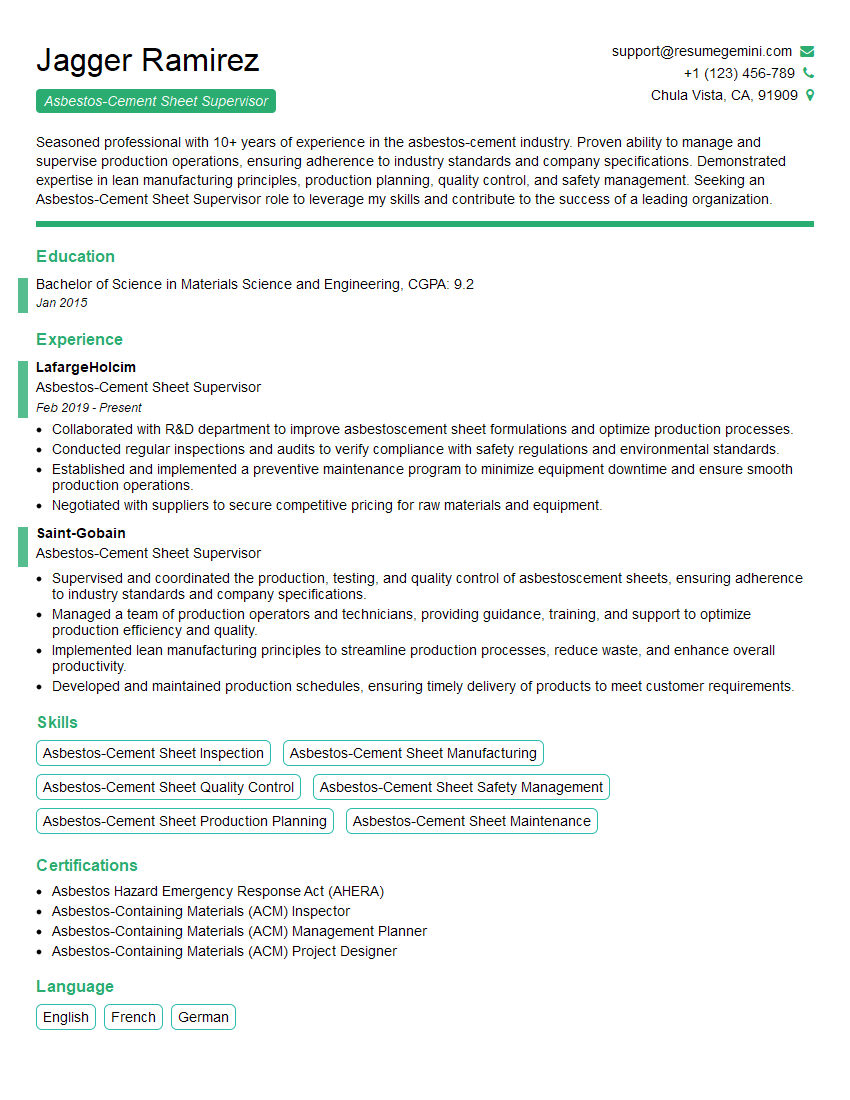

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asbestos-Cement Sheet Supervisor

1. Describe the process of producing asbestos-cement sheets.

The production of asbestos-cement sheets involves several key steps:

- Raw material preparation: Asbestos fibers, cement, and water are mixed to form a slurry.

- Sheet forming: The slurry is poured into a mold and pressed to form a flat sheet.

- Curing: The sheets are cured under controlled temperature and humidity conditions to allow the cement to harden and strengthen.

- Finishing: The cured sheets are trimmed, cut to size, and coated with a protective sealant.

2. What are the key quality control parameters for asbestos-cement sheets?

Dimensional accuracy:

- Conforms to specified thickness, width, and length

- Meets tolerances for flatness and squareness

Strength and durability:

- Meets specified flexural and tensile strength requirements

- Resists cracking, breakage, and weathering

Surface quality:

- Smooth and free of defects

- Uniform color and texture

3. Explain how you ensure compliance with safety regulations for asbestos handling.

Asbestos handling requires strict adherence to safety protocols. I ensure compliance through the following measures:

- Provide comprehensive safety training for all personnel

- Establish designated work areas with controlled access and proper ventilation

- Utilize personal protective equipment (PPE), including respirators, gloves, and protective clothing

- Implement regular air monitoring and dust suppression measures

- Dispose of asbestos waste according to established regulations

4. Describe the principles of lean manufacturing and how you apply them to optimize sheet production.

Lean manufacturing principles aim to eliminate waste and improve efficiency. I apply these principles by:

- Identifying and eliminating non-value-added activities

- Streamlining production flow and reducing lead times

- Improving inventory management and minimizing waste

- Empowering team members to participate in continuous improvement initiatives

- Utilizing data analysis and automation to enhance decision-making

5. What maintenance procedures are essential to ensure efficient and safe operation of sheet production equipment?

Regular maintenance is crucial to prevent breakdowns and accidents. I implement the following procedures:

- Establish a preventive maintenance schedule

- Conduct periodic inspections and lubrications

- Replace worn or damaged parts promptly

- Train operators on proper equipment use and troubleshooting

- Keep a detailed maintenance log for each piece of equipment

6. Discuss the importance of quality assurance in asbestos-cement sheet manufacturing.

Quality assurance ensures that products meet customer requirements and industry standards. I emphasize the following aspects:

- Establish and implement a comprehensive quality management system

- Conduct rigorous testing and inspection throughout the production process

- Empower employees to identify and resolve quality issues

- Analyze quality data to identify areas for improvement

- Maintain certification and accreditations to demonstrate adherence to industry best practices

7. Explain the environmental considerations in asbestos-cement sheet manufacturing.

Environmental protection is paramount in our operations. We adhere to the following measures:

- Minimize dust emissions through effective dust collection systems

- Implement proper waste disposal practices to prevent contamination

- Conserve energy and water resources

- Collaborate with regulatory agencies to comply with environmental regulations

- Educate employees on environmental best practices

8. What are the common challenges faced in asbestos-cement sheet production and how do you overcome them?

Challenges include:

Fiber dispersion:

- Implement effective ventilation and dust suppression systems

- Use protective equipment and train employees in safe handling

Curing process optimization:

- Control temperature, humidity, and pressure during curing

- Monitor curing progress using sensors and data analysis

Quality control:

- Establish clear quality standards and inspection procedures

- Empower employees to identify and resolve quality issues

9. What are your key strengths and how do they align with the requirements of this role?

My strengths include:

- Extensive experience in asbestos-cement sheet production

- Proven ability to manage production operations efficiently

- Strong technical knowledge and understanding of industry best practices

- Excellent communication and interpersonal skills

- Commitment to safety and quality

10. Why are you interested in working for our company and in this specific role?

I am impressed by your company’s reputation for excellence in the industry. This role aligns with my career goals and provides me with an opportunity to contribute my expertise to your team. I am confident that I can add value to your operations through my proven track record and commitment to delivering high-quality products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asbestos-Cement Sheet Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asbestos-Cement Sheet Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

As an Asbestos-Cement Sheet Supervisor, you will be responsible for overseeing the production of asbestos-cement sheets, ensuring compliance with safety regulations, and maintaining a safe and efficient work environment.

1. Production Supervision

Manage and supervise the production of asbestos-cement sheets, ensuring that all processes are carried out according to established specifications and quality standards.

- Monitor production lines to ensure optimal efficiency and identify potential bottlenecks.

- Provide technical guidance to operators and maintain production schedules.

2. Quality Control

Implement and enforce quality control procedures to ensure the production of defect-free asbestos-cement sheets.

- Inspect raw materials and finished products to ensure they meet specifications.

- Conduct regular audits and inspections to maintain quality standards.

3. Safety Management

Enforce strict adherence to all applicable safety regulations and guidelines.

- Conduct regular safety inspections, risk assessments, and training.

- Maintain a clean and organized work environment.

4. Regulatory Compliance

Stay updated on industry regulations and ensure that all operations comply with legal requirements.

- Obtain and maintain necessary permits and licenses.

- Monitor environmental impact and implement appropriate measures for waste management.

5. Team Management

Lead, motivate, and develop a team of production operators, ensuring a positive and collaborative work environment.

- Assign tasks, provide training, and evaluate performance.

- Foster a culture of continuous improvement and innovation.

Interview Tips:

To ace your interview for the Asbestos-Cement Sheet Supervisor position, consider the following tips:

1. Research the Company and Industry:

Demonstrate your interest in the company and the asbestos-cement industry. Familiarize yourself with their products, processes, and safety protocols.

2. Highlight Your Technical Expertise:

Emphasize your knowledge of asbestos-cement sheet production, quality control procedures, and safety management practices.

3. Showcase Your Leadership Skills:

Describe your experience in leading and motivating teams, setting clear expectations, and resolving conflicts.

4. Prepare for Technical Questions:

Be prepared to answer questions about specific aspects of asbestos-cement sheet production, such as mixing proportions, curing processes, and testing methods.

5. Emphasize Your Safety Consciousness:

Highlight your commitment to safety and your experience in implementing and enforcing safety regulations.

6. Practice Your Communication Skills:

Practice your communication skills to clearly and effectively convey your knowledge and experience.

7. Dress Professionally:

First impressions matter, so dress professionally to show respect for the interviewers and the company.

8. Be Confident and Enthusiastic:

Be confident and enthusiastic about your abilities and your desire to join the company.

Next Step:

Now that you’re armed with the knowledge of Asbestos-Cement Sheet Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Asbestos-Cement Sheet Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini