Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ash Conveyor Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

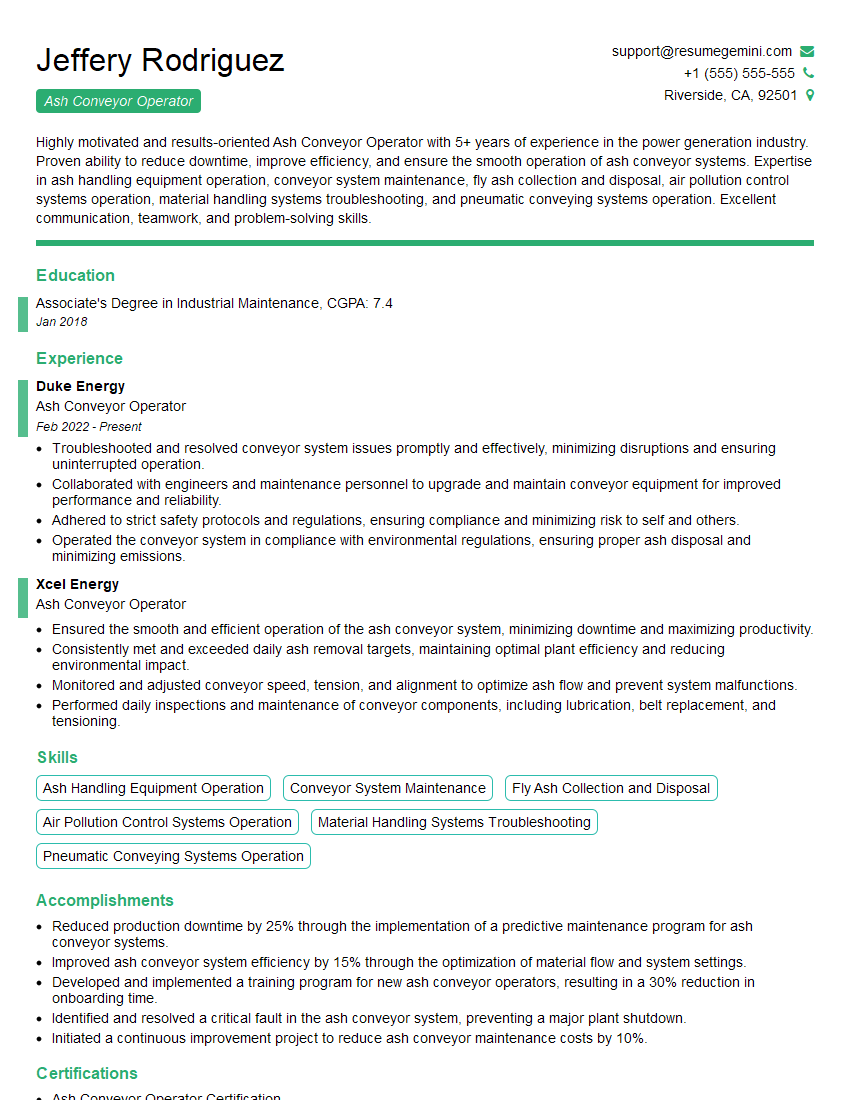

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ash Conveyor Operator

1. Explain the process of loading ash into the conveyor system?

The process of loading ash into the conveyor system involves several steps:

– Preparation: Ensure the conveyor system is operational and ready for use.

– Ash collection: Collect ash from various sources, such as boilers and precipitators.

– Transportation: Transport the collected ash to the conveyor loading point.

– Loading: Utilize a loading device, such as a front-end loader or vacuum truck, to transfer the ash onto the conveyor belt.

– Monitoring: Monitor the loading process to ensure smooth operation and prevent spillage.

2. How do you ensure the safe operation of the ash conveyor system?

Compliance with Regulations:

- Adhere to all applicable safety regulations and guidelines.

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and gloves.

Regular Maintenance and Inspection:

- Perform routine inspections of the conveyor system, including belts, rollers, and drive components.

- Identify and address any potential hazards or areas of concern promptly.

- Schedule regular maintenance to ensure the system operates reliably and efficiently.

Training and Supervision:

- Provide comprehensive training to all operators on safety procedures, emergency response plans, and proper operation of the system.

- Supervise operators and monitor their performance to ensure compliance with safety protocols.

Emergency Preparedness:

- Establish clear emergency response plans and communicate them to all personnel.

- Conduct regular drills to ensure readiness and response effectiveness.

3. How do you handle ash buildup and blockages in the conveyor system?

To effectively handle ash buildup and blockages in the conveyor system:

– Regular Cleaning and Monitoring: Regularly clean and inspect the conveyor system to remove accumulated ash and identify potential blockage points.

– Use of High-Pressure Water Jets: Utilize high-pressure water jets to dislodge and remove ash buildup or blockages from the conveyor belt and components.

– Manual Removal: In cases of severe blockages, manually remove the ash buildup or blockages while ensuring safety precautions are followed.

– System Modifications: If frequent blockages occur, consider modifying the system design or installing additional equipment to prevent or minimize future blockages.

– Training and Communication: Train operators on proper cleaning and maintenance techniques, and ensure clear communication to address blockages promptly.

4. Describe the different types of ash handling equipment used in the conveyor system and their functions?

- Belt Conveyors: Transport ash over long distances, providing a continuous flow of material.

- Screw Conveyors: Move ash horizontally or at an incline, capable of handling large volumes.

- Bucket Elevators: Lift ash vertically, used in conjunction with other conveyors for multi-level systems.

- Pneumatic Conveyors: Utilize compressed air to transport ash through pipelines, suitable for enclosed environments.

- Vacuum Trucks: Collect and transport ash from various locations, offering flexibility and mobility.

5. Explain the maintenance procedures you follow to ensure the conveyor system operates at peak efficiency?

- Regular Inspection: Conduct regular visual inspections to identify any signs of wear, damage, or misalignment.

- Belt Tensioning: Ensure proper belt tension to prevent slippage and premature wear.

- Roller Maintenance: Regularly lubricate and replace rollers to minimize friction and maintain smooth operation.

- Cleaning and Debris Removal: Clean the conveyor system to remove accumulated ash and debris, preventing blockages and ensuring efficient operation.

- Component Replacement: Replace worn or damaged components promptly to maintain system reliability and efficiency.

6. How do you troubleshoot and resolve common problems in the ash conveyor system?

- Belt Misalignment: Adjust the alignment of the conveyor belt to prevent material spillage and premature wear.

- Blockages: Identify and remove blockages in the conveyor system to restore material flow.

- Electrical Faults: Troubleshoot and repair electrical faults to ensure proper operation of motors, sensors, and other electrical components.

- Mechanical Issues: Diagnose and resolve mechanical issues, such as bearing failures or gearbox problems, to maintain system functionality.

- Ash Buildup: Implement measures to reduce ash buildup and prevent blockages, such as using high-pressure water jets or modifying the system design.

7. Describe your experience in working with different types of ash, including fly ash and bottom ash?

I have extensive experience working with various types of ash, including fly ash and bottom ash.

– Fly Ash: Fly ash is a fine, powdery material that requires special handling techniques to prevent fugitive dust emissions. I am proficient in utilizing dust collectors and proper ventilation systems to mitigate these issues.

– Bottom Ash: Bottom ash is typically coarser and more abrasive than fly ash. I have experience working with heavy-duty conveyor systems designed to handle this type of material, ensuring efficient and safe operation.

8. How do you stay up-to-date on the latest industry standards and best practices for ash handling?

- Attend Industry Conferences and Webinars: Participate in industry events to learn about new technologies and best practices.

- Read Trade Publications and Technical Journals: Stay informed about the latest advancements and research in the field.

- Seek Continuing Education and Training: Pursue further education and training opportunities to enhance my knowledge and skills.

- Network with Other Professionals: Engage with colleagues and industry experts to exchange ideas and stay abreast of industry trends.

9. How do you ensure that the ash conveyor system meets environmental compliance regulations?

To ensure compliance with environmental regulations, I implement the following measures:

– Proper Ash Handling and Disposal: Adhere to established procedures for ash handling and disposal, minimizing environmental impact.

– Fugitive Dust Control: Utilize dust collectors, water sprays, and other measures to control fugitive dust emissions during ash handling operations.

– Monitoring and Reporting: Conduct regular monitoring of ash emissions and submit reports to regulatory authorities as required.

– Spill Prevention and Response: Establish spill prevention and response plans to minimize the impact of any accidental releases of ash.

– Training and Awareness: Provide training to personnel on environmental regulations and proper ash handling practices.

10. Describe your experience in working with automated ash handling systems?

I have experience working with both manual and automated ash handling systems.

– Manual Systems: I am proficient in manually operating ash handling equipment, including conveyor belts, bucket elevators, and vacuum trucks.

– Automated Systems: I have worked with PLC-controlled automated ash handling systems that utilize sensors, actuators, and other components to optimize system operation.

– Troubleshooting and Maintenance: I am capable of troubleshooting and performing maintenance on automated ash handling systems, ensuring their reliable and efficient operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ash Conveyor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ash Conveyor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Ash Conveyor Operator, you will play a key role in ensuring the efficient and safe operation of ash conveyor systems. Your responsibilities will include:

1. Monitor and Control Conveyor Systems

You will be responsible for monitoring the conveyor system and making any necessary adjustments to ensure optimal performance. This may include:

- Starting, stopping, and adjusting the speed of conveyors

- Observing conveyor components for signs of wear or damage

- Reporting any problems or irregularities to supervisors

2. Maintain and Repair Equipment

You will perform routine maintenance and repairs on conveyor systems to ensure smooth operation. This may involve:

- Lubricating moving parts

- Tightening bolts and screws

- Replacing worn or damaged components

- Cleaning and inspecting conveyors

3. Ensure Safety and Compliance

You will be responsible for ensuring the safety of yourself and others while operating conveyor systems. This may include:

- Following all safety protocols and regulations

- Using proper protective equipment

- Reporting any unsafe conditions or practices

- Maintaining a clean and organized work area

4. Communicate with Operators and Supervisors

You will communicate with operators and supervisors to coordinate activities and ensure smooth operation of conveyor systems. This may involve:

- Providing updates on the status of conveyor systems

- Reporting any problems or delays

- Receiving instructions and guidance

- Participating in safety meetings and training sessions

Interview Tips

To help you ace your interview for an Ash Conveyor Operator position, here are some tips:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand their business, industry, and the role you would be playing.

2. Practice Your Answers

Think about common interview questions and practice your answers. This will help you feel more confident and prepared during the interview. Some common interview questions include:

- “Tell us about your experience operating ash conveyor systems.”

- “What are some of the challenges you’ve faced in this role and how did you overcome them?”

- “How do you ensure safety while operating conveyor systems?”

- “What are some best practices for conveyor maintenance?”

- “Why are you interested in this position at our company?”

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or business casual attire.

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and positive about their work. Show the interviewer that you’re excited about the opportunity and that you’re confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ash Conveyor Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.