Feeling lost in a sea of interview questions? Landed that dream interview for Ash Kier Boiler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ash Kier Boiler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

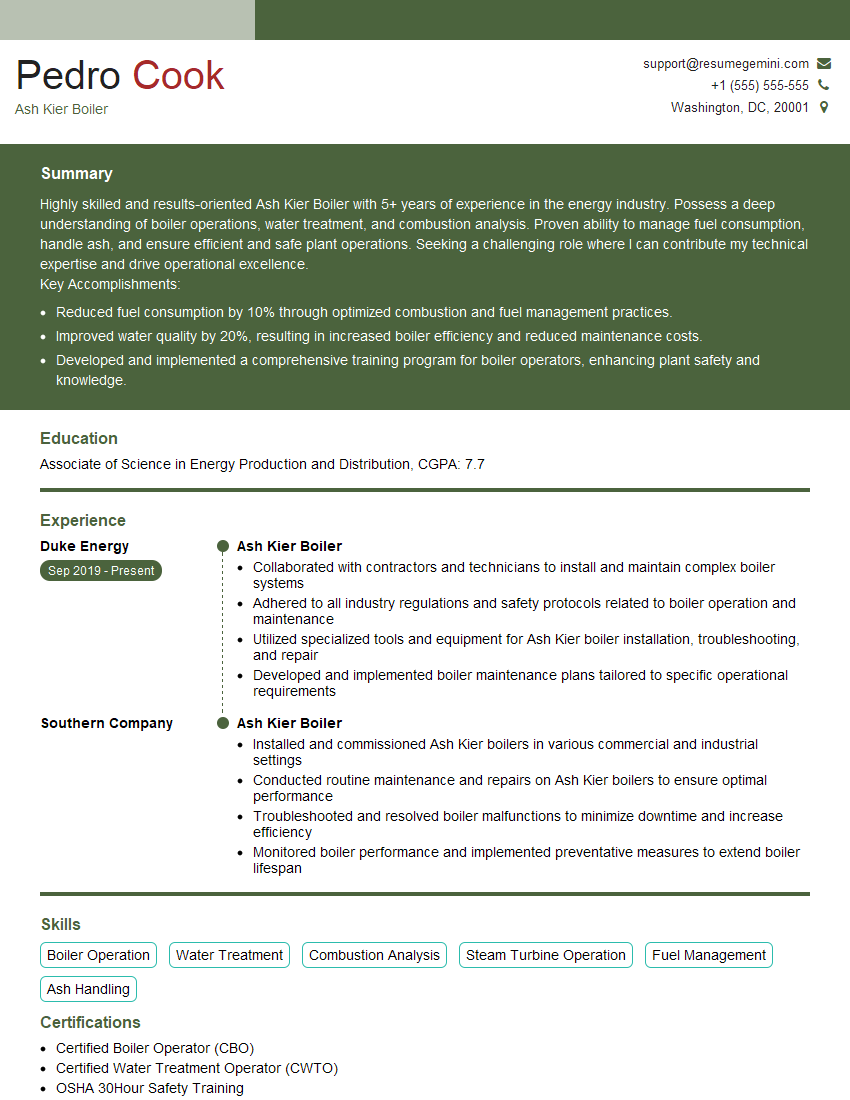

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ash Kier Boiler

1. Explain the concept of “Safety Integrity Level” (SIL) in the context of boiler operations. How do you determine and implement the required SIL for a given boiler application?

SIL is a measure of the likelihood of a system failing in a way that could cause harm to people, the environment, or equipment. In the context of boiler operations, SIL is used to determine the level of protection required for a given application. The required SIL is typically determined through a risk assessment, which considers the potential hazards associated with the boiler and the consequences of a system failure. Once the required SIL has been determined, it is necessary to implement measures to achieve that level of protection. These measures may include the use of redundant systems, fail-safe designs, and other risk reduction strategies.

2. Describe the typical maintenance procedures for a boiler system, including preventive maintenance, corrective maintenance, and predictive maintenance. How do you prioritize and schedule these maintenance activities?

Preventive maintenance

- Regular inspections and cleaning

- Lubrication and adjustment of moving parts

- Replacement of worn or damaged components

Corrective maintenance

- Repair or replacement of failed components

- Troubleshooting and diagnostics

Predictive maintenance

- Condition monitoring and diagnostics

- Trend analysis and failure prediction

The prioritization and scheduling of maintenance activities is based on the following factors:

- The criticality of the boiler system

- The risk of failure

- The cost of maintenance

- The availability of resources

3. Discuss the different types of boiler fuels and their relative advantages and disadvantages. How do you select the appropriate fuel for a given boiler application?

- Natural gas: Clean-burning, low emissions, high efficiency

- Oil: More expensive than natural gas, higher emissions, lower efficiency

- Coal: Dirty-burning, high emissions, low efficiency

- Biomass: Renewable, low emissions, but can be expensive

The selection of the appropriate fuel for a given boiler application is based on the following factors:

- The availability and cost of fuel

- The environmental regulations

- The boiler design

- The desired boiler performance

4. Explain the process of boiler commissioning and startup. What are the key steps involved and what are the safety considerations?

- Inspection of the boiler and all associated systems

- Filling the boiler with water

- Raising the boiler pressure and temperature

- Checking for leaks and other problems

- Synchronizing the boiler with the electrical grid

The following safety considerations are essential during boiler commissioning and startup:

- All personnel must be properly trained and qualified

- All safety procedures must be followed

- The boiler must be operated within its design limits

- All alarms and safety devices must be functioning properly

5. Describe the different methods for controlling boiler water chemistry. How do you monitor and maintain boiler water quality?

- Chemical treatment: Addition of chemicals to the boiler water to control pH, alkalinity, and dissolved solids

- Mechanical treatment: Use of filters, softeners, and demineralizers to remove impurities from the boiler water

- Blowdown: Removal of a portion of the boiler water to prevent the buildup of impurities

Boiler water quality is monitored by measuring the following parameters:

- pH

- Alkalinity

- Dissolved solids

- Conductivity

- Oxygen

6. Discuss the potential causes of boiler tube failures. How can these failures be prevented or mitigated?

- Overheating: Caused by insufficient water flow, scale buildup, or flame impingement

- Corrosion: Caused by acidic or corrosive boiler water, or exposure to oxygen

- Erosion: Caused by high-velocity water or steam flow

- Fatigue: Caused by repeated thermal cycling

Boiler tube failures can be prevented or mitigated by the following measures:

- Maintaining proper water flow and chemistry

- Preventing scale buildup

- Protecting the boiler from corrosion

- Minimizing thermal cycling

- Regular inspection and maintenance

7. Explain the operation of a boiler economizer. How does an economizer improve boiler efficiency and reduce emissions?

An economizer is a heat exchanger that preheats the boiler feedwater using the heat from the boiler flue gases. This reduces the amount of energy required to heat the feedwater, which in turn improves boiler efficiency. Economizers also reduce emissions by lowering the temperature of the flue gases, which reduces the formation of harmful pollutants such as nitrogen oxides (NOx) and sulfur oxides (SOx).

8. Describe the different types of boiler controls and their functions. How do these controls ensure safe and efficient boiler operation?

- Pressure controls: Regulate the boiler pressure to prevent overpressure or underpressure

- Temperature controls: Regulate the boiler temperature to prevent overheating or underheating

- Level controls: Regulate the boiler water level to prevent low water or high water conditions

- Fuel controls: Regulate the fuel flow to the boiler to maintain the desired firing rate

- Safety controls: Protect the boiler from hazardous conditions such as flame failure, low water, or high pressure

These controls ensure safe and efficient boiler operation by automatically responding to changes in operating conditions and taking corrective action as needed.

9. Explain the concept of “boiler efficiency” and how it is measured. What factors can affect boiler efficiency?

Boiler efficiency is a measure of how much of the energy in the fuel is converted into useful heat. It is typically expressed as a percentage, with higher percentages indicating higher efficiency. Boiler efficiency is measured by comparing the heat output of the boiler to the heat input of the fuel.

Factors that can affect boiler efficiency include:

- Boiler design

- Fuel type

- Boiler operating conditions

- Maintenance and upkeep

10. Discuss the environmental regulations that apply to boiler operations. How do you ensure that your boiler operations are in compliance with these regulations?

Boiler operations are subject to a variety of environmental regulations, including those governing air emissions, water discharge, and waste disposal. To ensure compliance with these regulations, it is important to:

- Familiarize yourself with the applicable regulations

- Implement measures to control emissions and discharges

- Monitor and record boiler operating data

- Report any violations to the appropriate authorities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ash Kier Boiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ash Kier Boiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ash Kier Boiler is responsible for managing the day-to-day operation of a boiler room. They ensure that the boiler is running efficiently and safely, and make repairs as needed.

1. Boiler Operation

The operator must be familiar with the boiler’s operation and maintenance procedures. They must be able to start, stop, and adjust the boiler to meet varying steam demands.

- Monitor boiler operation and make adjustments as needed

- Respond to boiler alarms and take corrective action

2. Boiler Maintenance

The operator must perform regular maintenance on the boiler, including cleaning, lubricating, and inspecting the boiler and its components. They must also keep a log of all maintenance activities.

- Perform routine maintenance on the boiler, including cleaning, lubricating, and inspecting

- Troubleshoot and repair boiler problems

3. Water Treatment

The operator must monitor the boiler’s water chemistry and make adjustments as needed to prevent corrosion and scaling. They must also blow down the boiler to remove impurities.

- Monitor boiler water chemistry and make adjustments as needed

- Blow down the boiler to remove impurities

4. Safety

The operator must follow all safety procedures when working on the boiler. They must wear appropriate personal protective equipment and be aware of the potential hazards associated with boiler operation.

- Follow all safety procedures when working on the boiler

- Wear appropriate personal protective equipment

Interview Tips

To ace your interview for an Ash Kier Boiler position, there are a few things you can do to prepare.

1. Research the Company

Before your interview, take some time to research the company. This will help you understand their business, culture, and values. You can visit the company’s website, read news articles, and talk to people who work there.

- Visit the company’s website

- Read news articles about the company

2. Practice Your Answers

Once you have researched the company, you can start practicing your answers to interview questions. You can write down your answers or practice them out loud. This will help you feel more confident and prepared during your interview.

- Write down your answers to common interview questions

- Practice your answers out loud

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear clean, pressed clothes

- Dress in a business suit or business casual attire

4. Be Punctual

Punctuality is important for any interview, but it is especially important for an Ash Kier Boiler interview. This shows that you are reliable and respectful of the interviewer’s time.

- Arrive on time for your interview

- If you are running late, call the interviewer and let them know

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ash Kier Boiler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ash Kier Boiler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.