Are you gearing up for an interview for a Asphalt Mixing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Asphalt Mixing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

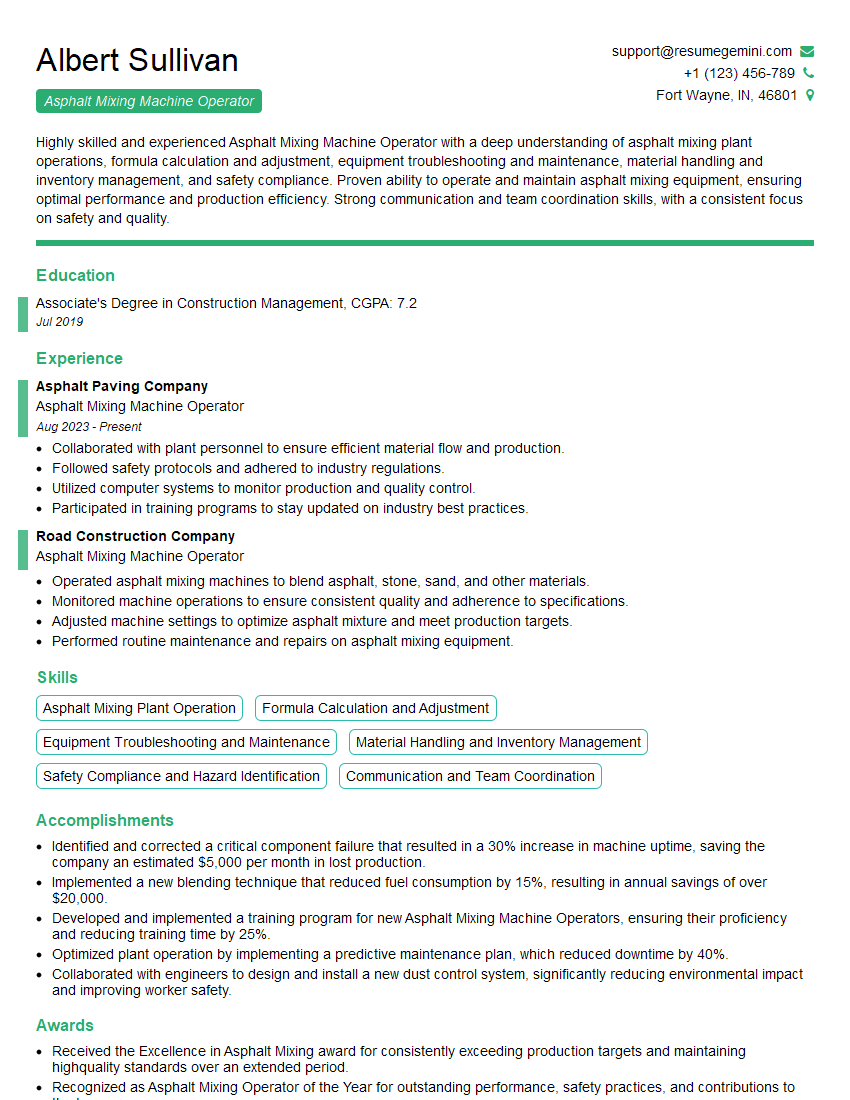

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Mixing Machine Operator

1. Describe the key components of an asphalt mixing machine?

The key components of an asphalt mixing machine are:

- Aggregate bins: These bins hold the different sizes of aggregate that will be used in the asphalt mix.

- Asphalt binder tank: This tank holds the asphalt binder that will be mixed with the aggregate.

- Mixer: This unit mixes the aggregate and asphalt binder together to create the asphalt mix.

- Discharge chute: This chute allows the asphalt mix to be discharged from the machine.

- Control panel: This panel allows the operator to control the machine’s functions, such as the temperature of the asphalt binder and the speed of the mixer.

2. What are the different types of asphalt mixes?

Hot mix asphalt (HMA):

- Most common type of asphalt mix

- Made with heated aggregate and asphalt binder

- Compacted at high temperatures

Warm mix asphalt (WMA):

- Similar to HMA, but mixed at lower temperatures

- Uses additives to reduce the temperature at which the asphalt binder can be mixed and compacted

Cold mix asphalt (CMA):

- Mixed at ambient temperatures

- Uses a liquid asphalt binder that is emulsified with water

- Compacted at low temperatures

3. What are the factors that affect the quality of asphalt mix?

- Quality of the aggregate

- Quality of the asphalt binder

- Gradation of the aggregate

- Temperature of the asphalt mix

- Compaction of the asphalt mix

4. What are the safety precautions that must be taken when operating an asphalt mixing machine?

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, and gloves.

- Be aware of the moving parts of the machine and keep a safe distance.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for operating the machine.

5. What is the role of an asphalt mixing machine operator?

The role of an asphalt mixing machine operator is to operate the machine to produce asphalt mix. This involves:

- Loading the machine with aggregate and asphalt binder

- Setting the machine’s controls to the desired temperature and speed

- Monitoring the machine’s operation and making adjustments as needed

- Ensuring that the asphalt mix is produced to the required specifications

- Cleaning and maintaining the machine

6. What are the qualifications to become an asphalt mixing machine operator?

- High school diploma or equivalent

- Experience operating heavy machinery

- Knowledge of asphalt mix production

- Ability to read and understand technical manuals

- Good communication and interpersonal skills

7. What are the career opportunities for asphalt mixing machine operators?

- Asphalt paving crew foreman

- Asphalt plant manager

- Construction manager

- Quality control inspector

- Sales representative

8. What is the average salary for an asphalt mixing machine operator?

The average salary for an asphalt mixing machine operator is $50,000 per year.

9. What are the benefits of working as an asphalt mixing machine operator?

- Competitive salary and benefits

- Opportunity to work outdoors

- Chance to learn a valuable trade

- Job security

- Opportunity for advancement

10. What are the challenges of working as an asphalt mixing machine operator?

- Working in all weather conditions

- Working long hours

- Being exposed to loud noise and dust

- Operating heavy machinery

- Working in a team environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Mixing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Mixing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Asphalt Mixing Machine Operators play a crucial role in the production of asphalt, a vital material used in road construction and pavement maintenance. Their primary responsibilities involve operating and maintaining asphalt mixing equipment to ensure efficient and high-quality production.

1. Machine Operation

– Operate asphalt mixing machines, feeding raw materials such as aggregate, bitumen, and additives into the mixer.

– Control the mixing process, adjusting settings to meet specified proportions and temperatures.

– Monitor the production process, ensuring smooth operation and maintaining optimal output.

2. Maintenance and Troubleshooting

– Perform regular maintenance tasks on asphalt mixing machines, including lubrication, cleaning, and adjustments.

– Identify and troubleshoot equipment malfunctions or breakdowns, promptly addressing issues to minimize downtime.

– Maintain accurate maintenance records and report any significant issues to supervisors.

3. Quality Control

– Collect and test asphalt samples to ensure they meet quality standards.

– Adjust mixing parameters based on test results to maintain consistent product quality.

– Comply with established quality control procedures and document all relevant data.

4. Safety and Compliance

– Adhere to all safety regulations and guidelines related to asphalt mixing operations.

– Wear appropriate personal protective equipment (PPE) and follow established safety protocols.

– Participate in safety training programs and maintain a safe working environment.

Interview Tips

Preparing for an interview for an Asphalt Mixing Machine Operator position requires a well-rounded approach that encompasses technical knowledge, problem-solving skills, and a commitment to safety. Here are some tips to help you ace the interview:

1. Research the Company and Position

– Gather information about the company’s background, values, and current projects.

– Review the job description thoroughly to understand the specific responsibilities and requirements.

2. Highlight Your Technical Skills

– Showcase your experience in operating and maintaining asphalt mixing machines.

– Discuss your knowledge of the mixing process and quality control procedures.

– Provide examples of how you have addressed equipment malfunctions or breakdowns.

3. Emphasize Safety Awareness

– Stress your commitment to safety and your adherence to industry regulations.

– Explain your experience in following PPE protocols and maintaining a safe working environment.

– Highlight any safety certifications or training programs you have completed.

4. Practice Common Interview Questions

– Prepare answers to common interview questions related to your experience, skills, and career goals.

– Practice the STAR method (Situation, Task, Action, Result) to effectively convey your experiences.

– Consider using behavioral interview questions to demonstrate your problem-solving abilities and teamwork skills.

5. Prepare Questions for the Interviewer

– Ask thoughtful questions to demonstrate your interest in the position and the company.

– Inquire about the company’s current projects, growth opportunities, and safety initiatives.

– Asking questions shows that you are engaged and invested in the interview process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Asphalt Mixing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.