Are you gearing up for an interview for a Asphalt Paver Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Asphalt Paver Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

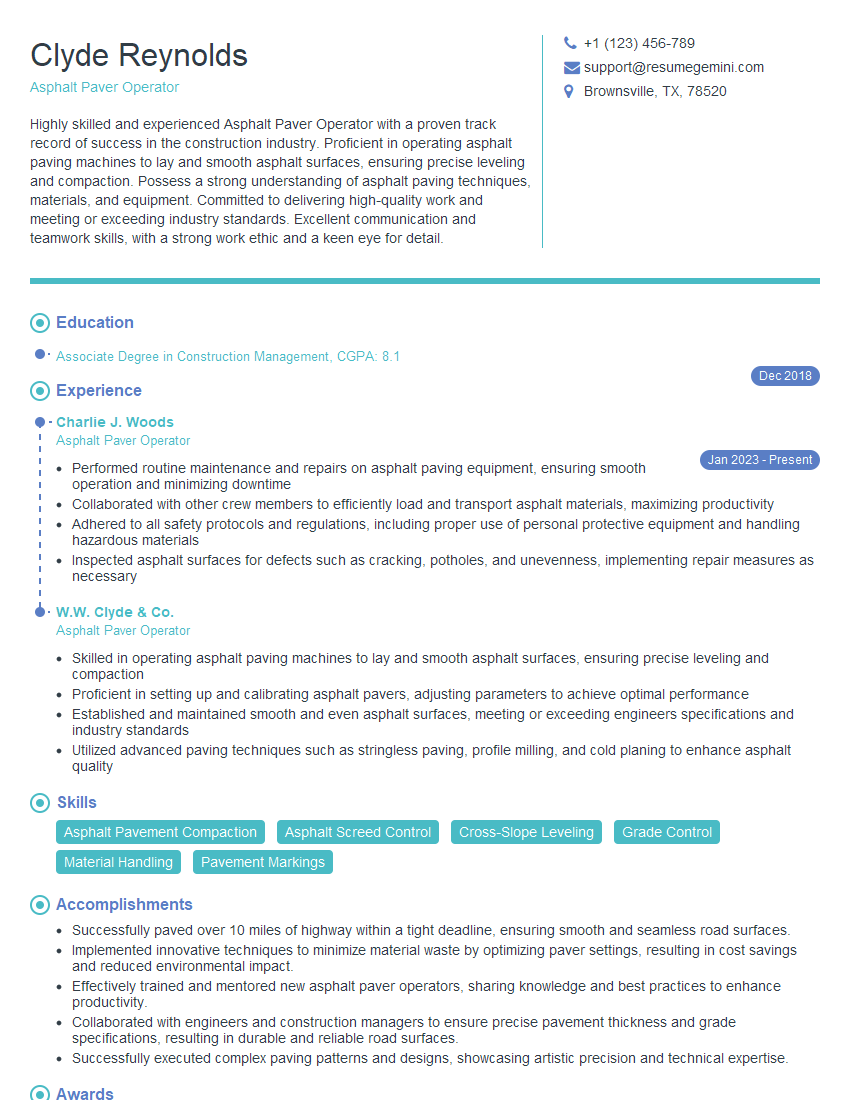

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Paver Operator

1. Explain the process of setting up and operating an asphalt paver?

Setting up an asphalt paver involves:

- Checking the paver for any damage or issues

- Calibrating the paver according to the specifications of the project

- Setting up the screed and extensions to the desired width

- Ensuring that the paver is level and stable

Operating an asphalt paver includes:

- Loading the paver with asphalt mix

- Controlling the paver’s speed and direction

- Adjusting the screed to achieve the desired mat thickness and smoothness

- Monitoring the paver’s operation and making adjustments as needed

2. Describe the different types of asphalt mixes and their applications?

Hot Mix Asphalt

- Most commonly used in paving roads, highways, and parking lots

- Mixed at high temperatures and applied hot

- Provides good durability, strength, and resistance to wear and tear

Warm Mix Asphalt

- Mixed at lower temperatures than hot mix asphalt

- Easier to handle and work with, reducing emissions

- Suitable for use in areas with lower traffic volumes or where environmental concerns are a priority

Cold Mix Asphalt

- Mixed at ambient temperatures and applied cold

- Used for temporary repairs, patching, and in areas where immediate use is required

- Less durable than hot mix asphalt, but provides quick and easy application

Asphalt Rubber

- Contains recycled rubber from scrap tires

- Provides increased flexibility and resistance to cracking

- Suitable for use in areas with heavy traffic or extreme temperature variations

3. What are the common problems encountered while operating an asphalt paver and how do you troubleshoot them?

- Tearing or raveling: Caused by incorrect mix temperature, poor compaction, or excessive moisture. Can be resolved by adjusting the mix temperature, compaction settings, or drainage.

- Rutting: Occurs when the asphalt is too soft and deforms under heavy traffic. Can be prevented by using a stiffer mix, increasing compaction, or reinforcing the subgrade.

- Bleeding: When excess asphalt rises to the surface, creating a slippery and uneven surface. Caused by high mix temperature, poor drainage, or excessive traffic. Can be resolved by lowering the mix temperature, improving drainage, or limiting traffic.

- Cracking: Caused by thermal stresses, traffic loading, or aging. Can be minimized by using a flexible mix, providing adequate drainage, and sealing cracks promptly.

4. How do you ensure the accuracy and quality of the asphalt pavement laid?

- Proper calibration and setup: Ensure the paver is calibrated according to project specifications and is operating at the correct speed and temperature.

- Monitoring the mix: Check the mix temperature, gradation, and moisture content to ensure it meets specifications.

- Adjusting the screed: Continuously monitor the screed to maintain the desired mat thickness and smoothness, using level sensors and visual inspection.

- Compaction: Ensure the asphalt is adequately compacted using rollers of appropriate weight and type, following the rolling pattern specified.

- Testing and quality control: Conduct field tests such as density and smoothness measurements to verify compliance with project requirements.

5. What safety precautions should be taken when operating an asphalt paver?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a hard hat.

- Be aware of the surroundings and potential hazards, including moving equipment, hot asphalt, and traffic.

- Follow proper lockout/tagout procedures when servicing or repairing the paver.

- Maintain a safe distance from the paver’s moving parts and hot surfaces.

- Communicate clearly with other crew members and follow established hand signals.

6. How do you maintain and service an asphalt paver to ensure optimal performance?

- Daily maintenance: Inspect the paver for any damage or issues, clean the screed and other components, and check fluid levels.

- Regular servicing: Perform scheduled maintenance tasks such as changing oil and filters, greasing bearings, and calibrating sensors.

- Repairs: Address any repairs promptly to prevent further damage or downtime. Follow manufacturer’s guidelines and use genuine parts.

- Winterization: Prepare the paver for winter storage by draining fluids, cleaning components, and applying protective coatings.

- Record keeping: Maintain accurate records of maintenance and repairs to track the paver’s condition and identify trends.

7. Describe your experience in working with different types of asphalt pavers and equipment?

I have experience operating various types of asphalt pavers, including both tracked and wheeled models. I am proficient in using different screed types, such as vibrating screeds for smoothness and tamper bars for high-density compaction. Additionally, I have experience with auxiliary equipment such as material transfer vehicles, rollers, and tack coat applicators.

8. How do you coordinate with other crew members to ensure efficient and safe operation of the asphalt paver?

- Communication: Establish clear lines of communication with the foreman, grade checkers, and roller operators.

- Teamwork: Work collaboratively to ensure smooth transitions between paving operations and other tasks.

- Safety: Communicate potential hazards and follow established safety protocols to protect the crew and the public.

- Problem-solving: Address any issues or discrepancies promptly and effectively to minimize delays.

- Continuous improvement: Share knowledge and ideas with crew members to enhance overall productivity and quality.

9. What factors influence the selection of the appropriate asphalt mix for a particular project?

- Traffic volume and type: Heavier traffic requires a more durable mix with higher stability.

- Climate conditions: Extreme temperatures, moisture, and UV exposure can affect the performance of the mix.

- Subgrade condition: A weak subgrade may require a thicker or reinforced asphalt layer.

- Project specifications: Specific requirements may dictate the type of mix used, such as its gradation, density, and performance properties.

- Environmental concerns: The use of recycled materials or warm mix asphalt can reduce environmental impact.

10. How do you manage the challenges of working in a fast-paced and demanding environment as an asphalt paver operator?

- Time management: Prioritize tasks and allocate time effectively to meet deadlines without compromising quality.

- Adaptability: Quickly adjust to changing conditions, unexpected delays, and equipment issues.

- Stress management: Maintain composure under pressure and make informed decisions in challenging situations.

- Physical endurance: Work long hours in physically demanding conditions, including heat, noise, and fumes.

- Safety awareness: Stay vigilant and adhere to safety protocols to prevent accidents and injuries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Paver Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Paver Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Asphalt Paver Operator is responsible for operating and maintaining asphalt paving equipment used in the construction and repair of roads, highways, and other paved surfaces. Key job responsibilities include:1. Operating Asphalt Pavers

Operate asphalt pavers in accordance with established procedures to ensure proper placement and compaction of asphalt.

- Set up and position the paver according to specifications.

- Control the flow of asphalt into the paver and onto the road surface.

- Adjust paver settings to ensure the desired thickness, width, and smoothness of the asphalt.

2. Maintaining Equipment

Perform routine maintenance and repairs on asphalt paving equipment to ensure optimal performance.

- Inspect equipment for wear and damage.

- Change filters, fluids, and other consumables.

- Troubleshoot and resolve equipment malfunctions.

3. Safety and Compliance

Adhere to safety regulations and industry best practices to ensure the safety of themselves, coworkers, and the public.

- Wear appropriate personal protective equipment (PPE).

- Follow proper procedures for handling and storing asphalt.

- Maintain a clean and organized work area.

4. Quality Control

Monitor the quality of asphalt pavement work and make adjustments as needed to ensure compliance with specifications.

- Take samples of asphalt for testing.

- Inspect finished pavement for smoothness and compaction.

- Make adjustments to paver settings or work practices based on test results and inspections.

Interview Tips

To ace the interview for an Asphalt Paver Operator position, candidates should consider the following tips:1. Research the Company and Position

Familiarize yourself with the company’s history, operations, and the specific requirements of the Asphalt Paver Operator role.

- Visit the company’s website and read about their products, services, and culture.

- Review the job description thoroughly and identify the key skills and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining asphalt paving equipment and your commitment to safety.

- Quantify your accomplishments whenever possible. For example, describe how you increased productivity by implementing a new maintenance schedule.

- Provide specific examples of how you have resolved equipment malfunctions or ensured the quality of asphalt pavement work.

3. Demonstrate Enthusiasm and Motivation

Express your interest in the position and the industry, and explain why you are a good fit for the company.

- Share your passion for construction and paving work.

- Describe how you stay up-to-date with industry best practices and advancements.

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer during the interview. This shows that you are interested in the position and the company.

- Inquire about the company’s current projects and their future plans.

- Ask about the company’s commitment to safety and environmental sustainability.

5. Professional Presentation

Dress appropriately for the interview, arrive on time, and be polite and respectful to everyone you meet.

- Choose clothing that is clean, pressed, and suitable for a construction environment.

- Be punctual and allow plenty of time to find the interview location.

- Make eye contact, smile, and introduce yourself with confidence.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Asphalt Paver Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.