Feeling lost in a sea of interview questions? Landed that dream interview for Asphalt Plant Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Asphalt Plant Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

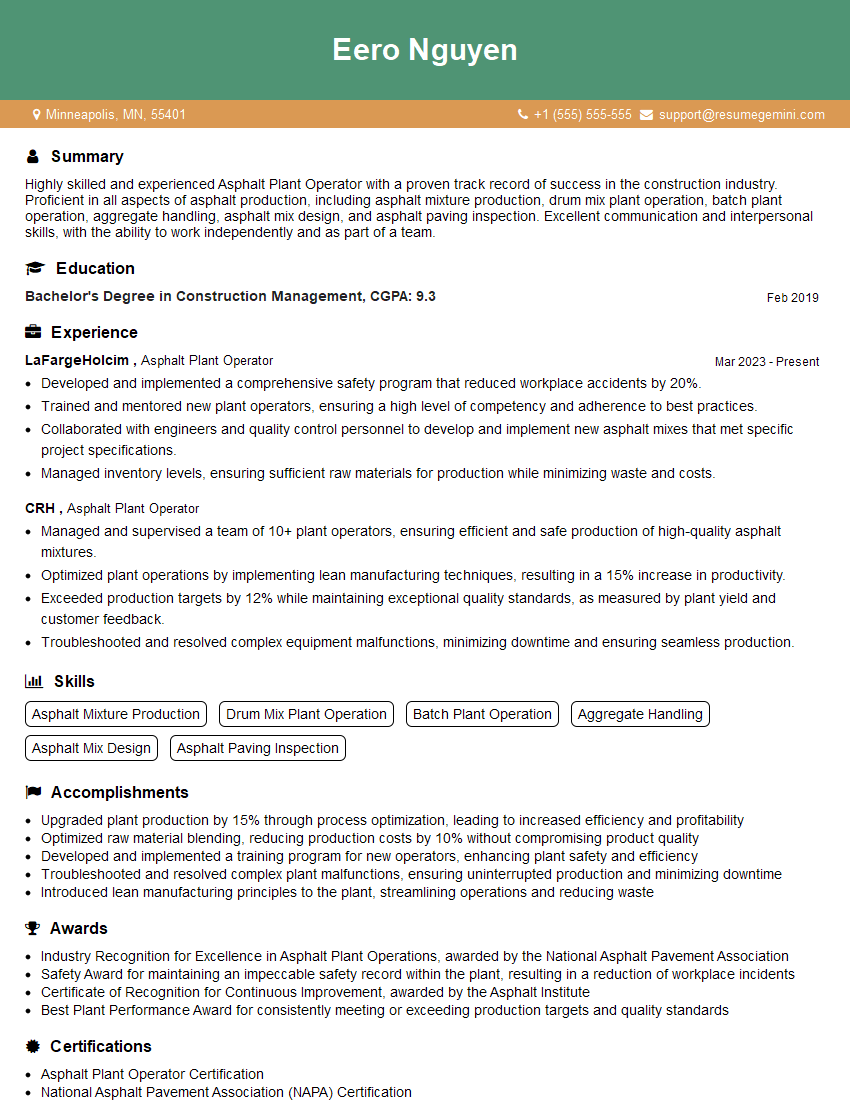

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Plant Operator

1. What are the key responsibilities of an Asphalt Plant Operator?

As an Asphalt Plant Operator, my key responsibilities include:

- Operate and maintain asphalt mixing equipment, including mixers, pug mills, and conveyors

- Monitor and adjust asphalt mix ingredients, such as aggregate, sand, and asphalt cement, to meet specifications

2. Describe the process of producing asphalt mix.

Mixing

- Load aggregate, sand, and asphalt cement into the mixer

- Operate the mixer to blend the ingredients until a uniform mix is achieved

Quality Control

- Monitor mix temperature and density to ensure it meets specifications

- Collect and test samples of the mix to verify quality

Loading and Dispatching

- Load asphalt mix into trucks or other transport vehicles

- Coordinate with truck drivers and dispatchers to ensure timely delivery of asphalt mix to construction sites

3. What are some common problems that can occur during asphalt production and how do you resolve them?

Some common problems include:

- Overheating: Overheating can cause the asphalt to become stiff and difficult to work with. To resolve this, reduce the temperature of the mix or add cold aggregate.

- Segregation: Segregation occurs when the different components of the asphalt mix separate. To resolve this, increase the mixing time or adjust the proportions of the ingredients.

- Porosity: Porosity can lead to cracking and premature failure of the asphalt pavement. To resolve this, increase the density of the mix or use a different type of aggregate.

4. How do you ensure the safety of yourself and others when working at an asphalt plant?

Safety is my top priority. I adhere to all safety regulations and wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and earplugs.

- I always inspect equipment before operating it and report any potential hazards to my supervisor.

- I follow established lockout/tagout procedures when performing maintenance or repairs.

- I am aware of the location of emergency exits and firefighting equipment.

5. What is your experience with troubleshooting and repairing asphalt plant equipment?

I have experience troubleshooting and repairing a variety of asphalt plant equipment, including:

- Mixers

- Pug mills

- Conveyors

- Boilers

- Dust collectors

I am able to identify common problems and quickly implement solutions to minimize downtime and maintain efficient plant operation.

6. What are some of the challenges you have faced as an Asphalt Plant Operator and how did you overcome them?

One of the biggest challenges I have faced is maintaining consistent mix quality during periods of high demand.

- To overcome this, I worked closely with the quality control team to optimize the mix design and implement rigorous testing procedures.

- I also coordinated with the logistics team to ensure a steady supply of materials and minimize production delays

7. How do you stay up-to-date on the latest developments in asphalt production and technology?

I stay up-to-date on industry best practices through various methods:

- Attending industry conferences and workshops

- Reading technical publications and industry magazines

- Participating in online forums and discussion groups

- Consulting with equipment manufacturers and suppliers

8. What is your understanding of environmental regulations related to asphalt production?

I am familiar with environmental regulations related to asphalt production, including:

- Air quality regulations, such as those governing emissions of particulate matter and volatile organic compounds (VOCs)

- Water quality regulations, such as those governing stormwater runoff and wastewater discharge

- Solid waste regulations, such as those governing the disposal of asphalt waste and byproducts

I strive to comply with all applicable regulations and minimize the environmental impact of asphalt production

9. How do you handle working in a fast-paced and demanding production environment?

I thrive in fast-paced and demanding environments.

- I am able to prioritize tasks effectively and manage my time wisely.

- I am also comfortable working independently and as part of a team.

- I am committed to meeting deadlines and exceeding expectations

10. Why are you interested in this Asphalt Plant Operator position with our company?

I am eager to contribute my skills and experience to your company.

- I am particularly interested in your company’s commitment to safety and quality.

- I believe that my dedication to these values, combined with my technical expertise, would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Asphalt Plant Operator is a skilled professional responsible for operating, maintaining, and monitoring an asphalt plant, ensuring the production of high-quality asphalt for road construction and repair.

1. Plant Operation

Operate the asphalt plant’s machinery and equipment, including the mixer, heating system, and storage tanks.

- Adjust and calibrate plant settings to maintain optimal production levels and asphalt quality.

- Monitor plant processes, including temperature, pressure, and flow rates, to ensure safe and efficient operation.

2. Material Management

Control the flow of materials, including aggregates, bitumen, and additives, into the plant.

- Ensure a consistent supply of raw materials to meet production demands.

- Monitor the quality and quantity of materials received and adjust plant settings accordingly.

3. Equipment Maintenance

Perform basic maintenance and repairs on plant equipment, troubleshooting and resolving operational issues.

- Lubricate moving parts, replace filters, and clean equipment to prevent breakdowns.

- Notify supervisors of any major equipment issues or repairs that require specialized attention.

4. Safety and Environment

Maintain a safe working environment, adhering to industry regulations and company safety protocols.

- Wear appropriate personal protective equipment and follow safety procedures at all times.

- Monitor emissions and waste generated by the plant, ensuring compliance with environmental regulations.

Interview Tips

Preparing thoroughly for an Asphalt Plant Operator interview can significantly increase your chances of success.

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the specific company and the asphalt industry.

- Visit the company website to learn about their operations, values, and recent projects.

- Read industry publications and articles to stay updated on current trends and technologies.

2. Highlight Relevant Skills and Experience

Review the job description carefully and tailor your resume and answers to emphasize your relevant skills and experience.

- Quantify your accomplishments whenever possible, using specific numbers and data to demonstrate your impact.

- If you have prior experience operating asphalt plants, highlight your expertise in equipment operation, material management, and safety procedures.

3. Practice Common Interview Questions

Prepare for common interview questions by researching typical questions and practicing your responses.

- Develop concise and articulate answers that showcase your abilities and enthusiasm for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your accomplishments.

4. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing professionally and arriving on time for the interview.

- Wear clean, pressed clothing that is appropriate for an industrial setting.

- Plan your route in advance to avoid any delays and demonstrate your respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Asphalt Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!