Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Asphalt Still Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Asphalt Still Operator so you can tailor your answers to impress potential employers.

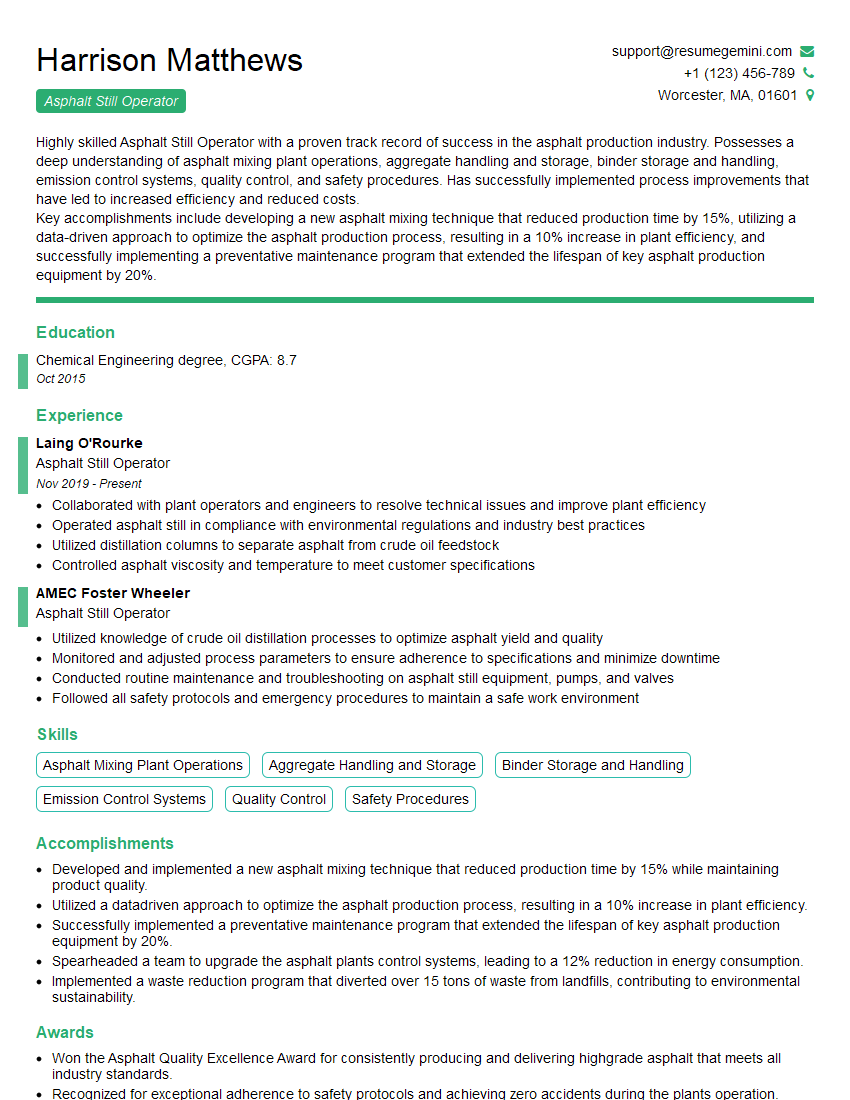

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Still Operator

1. What are the different types of asphalt stills and how do they operate?

There are two main types of asphalt stills: batch stills and continuous stills.

- Batch stills are used to produce small batches of asphalt, typically less than 100 tons. They operate by heating the asphalt feedstock in a tank until it reaches the desired temperature. The asphalt is then cooled and stored in a separate tank.

- Continuous stills are used to produce large batches of asphalt, typically more than 100 tons. They operate by continuously feeding the asphalt feedstock into a heated drum. The asphalt is then vaporized and condensed in a separate drum. The condensed asphalt is then stored in a tank.

2. What are the key operating parameters of an asphalt still and how do you control them?

Temperature

- The temperature of the asphalt still is one of the most important operating parameters. It must be controlled carefully to ensure that the asphalt is not overheated or underheated.

- The temperature of the asphalt still is controlled by adjusting the flow of heat into the still.

Pressure

- The pressure of the asphalt still is also an important operating parameter. It must be controlled carefully to ensure that the asphalt does not vaporize or condense.

- The pressure of the asphalt still is controlled by adjusting the flow of gas into the still.

Flow rate

- The flow rate of the asphalt still is the rate at which the asphalt feedstock is fed into the still. It must be controlled carefully to ensure that the still does not overflow or run dry.

- The flow rate of the asphalt still is controlled by adjusting the speed of the feed pump.

3. What are the safety hazards associated with operating an asphalt still and how do you mitigate them?

- The main safety hazards associated with operating an asphalt still are fire, explosion, and chemical burns.

- To mitigate the risk of fire, the asphalt still must be operated in a well-ventilated area and all sources of ignition must be removed.

- To mitigate the risk of explosion, the asphalt still must be equipped with a pressure relief valve and all gas lines must be properly sealed.

- To mitigate the risk of chemical burns, the asphalt still must be operated in accordance with all applicable safety regulations and all workers must wear appropriate personal protective equipment.

4. What are the maintenance procedures for an asphalt still and how often should they be performed?

- The maintenance procedures for an asphalt still include cleaning, inspecting, and repairing the still and its components.

- The still should be cleaned on a regular basis to remove any build-up of asphalt or other materials.

- The still should be inspected on a regular basis to identify any potential problems.

- The still should be repaired as needed to ensure that it is operating safely and efficiently.

5. What are the troubleshooting procedures for an asphalt still and how do you perform them?

- The troubleshooting procedures for an asphalt still include identifying the problem, determining the cause of the problem, and taking corrective action.

- To identify the problem, the operator should observe the still and its components for any unusual behavior.

- To determine the cause of the problem, the operator should check the still’s operating parameters and compare them to the desired values.

- To take corrective action, the operator should adjust the still’s operating parameters or repair the still’s components as needed.

6. What are the quality control procedures for asphalt and how do you ensure that the asphalt produced by your still meets the desired specifications?

- The quality control procedures for asphalt include testing the asphalt for its physical and chemical properties.

- The asphalt should be tested for its viscosity, penetration, and ductility.

- The asphalt should also be tested for its specific gravity, flash point, and fire point.

- The asphalt should meet the desired specifications for its intended use.

7. What are the environmental regulations that apply to asphalt stills and how do you ensure that your still complies with these regulations?

- The environmental regulations that apply to asphalt stills include the Clean Air Act, the Clean Water Act, and the Resource Conservation and Recovery Act.

- To ensure that your still complies with these regulations, you should obtain a permit from the appropriate regulatory authority.

- You should also develop and implement a plan to control air emissions, water discharges, and solid waste disposal.

8. What are the latest trends in asphalt still technology and how do you stay up-to-date on these trends?

- The latest trends in asphalt still technology include the use of new materials and new processes to improve the efficiency and environmental performance of stills.

- To stay up-to-date on these trends, you should read trade publications, attend industry conferences, and visit with manufacturers and suppliers.

9. What are your strengths and weaknesses as an Asphalt Still Operator?

My strengths as an Asphalt Still Operator include my:

- Experience and knowledge of the asphalt still process

- Ability to operate and maintain the still safely and efficiently

- Attention to detail and commitment to quality

My weaknesses include my:

- Lack of experience with some of the latest asphalt still technologies

- Limited knowledge of some of the environmental regulations that apply to asphalt stills

10. Why do you want to work as an Asphalt Still Operator for our company?

- I am interested in working for your company because of its reputation as a leader in the asphalt industry.

- I am confident that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about the latest asphalt still technologies and environmental regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Asphalt Still Operator, you will be responsible for the safe and efficient operation of an asphalt still, ensuring the production of high-quality asphalt pavement material. Your key job responsibilities include:

1. Asphalt Production

Operate and maintain the asphalt still, including monitoring temperatures, pressures, and flow rates to ensure optimal production.

- Calibrate and maintain equipment to ensure accurate measurements and control.

- Troubleshoot and resolve operational issues promptly to minimize downtime.

2. Quality Control

Monitor the quality of the asphalt produced, conducting tests and making adjustments as necessary to meet specifications.

- Collect and analyze samples to assess properties such as viscosity, penetration, and flash point.

- Make necessary adjustments to raw materials or process parameters to maintain product quality.

3. Equipment Maintenance

Perform routine maintenance and repairs on the asphalt still and related equipment to ensure smooth operation.

- Inspect, clean, and lubricate equipment regularly.

- Identify and repair minor malfunctions to prevent major breakdowns.

4. Safety Compliance

Adhere strictly to all safety regulations and procedures to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow established safety protocols.

- Report any potential hazards or unsafe conditions immediately.

Interview Tips

To ace your interview as an Asphalt Still Operator, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Research the specific responsibilities of the Asphalt Still Operator position.

2. Highlight Your Technical Skills

Emphasize your expertise in asphalt production, quality control, and equipment maintenance. Provide specific examples of your experience and skills.

3. Demonstrate Safety Awareness

Stress your commitment to safety and your knowledge of industry regulations. Share examples of how you have prioritized safety in previous roles.

4. Be Prepared for Industry Questions

Prepare answers to questions about the different types of asphalt, the impact of weather conditions on asphalt production, and common troubleshooting techniques.

5. Practice Your Interview Responses

Rehearse your answers to common interview questions, such as “Tell me about your experience operating an asphalt still” or “How do you ensure the quality of the asphalt produced?”

6. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving at the interview on time. Your appearance and punctuality convey respect and professionalism.

7. Be Confident and Enthusiastic

Approach the interview with confidence and enthusiasm. Believe in your abilities and demonstrate your passion for the field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Asphalt Still Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!