Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Assembled Wood Products Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

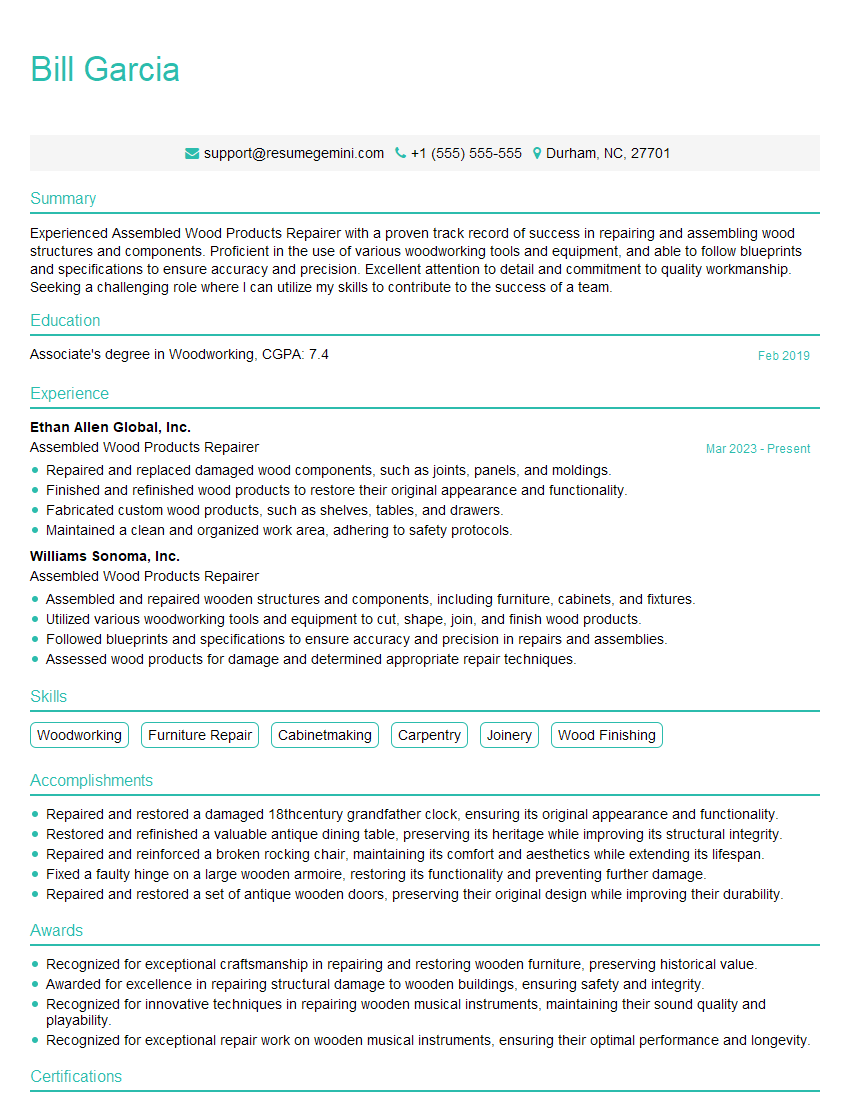

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembled Wood Products Repairer

1. Describe the process you would follow to repair a cracked wooden table?

- Inspect the crack and determine the extent of the damage.

- Clean the crack area and remove any debris or splinters.

- Apply wood glue to the crack and clamp it together.

- Allow the glue to dry completely.

- Sand the repaired area smooth.

- Apply a finish to the repaired area to protect it.

2. What are the different types of wood joints used in furniture making?

Mortise and tenon joint

- A mortise and tenon joint is a strong and durable joint that is often used in furniture making.

- It is made by cutting a mortise (a square or rectangular hole) into one piece of wood and a tenon (a protruding tongue) into the other piece of wood.

- The tenon is then inserted into the mortise and the joint is secured with glue or nails.

Dowel joint

- A dowel joint is a simple and quick to make joint that is often used in furniture making.

- It is made by drilling two holes into the two pieces of wood that need to be joined and inserting a dowel (a cylindrical piece of wood) into the holes.

- The dowel is then glued into place and the joint is complete.

3. What are the different types of wood finishes used in furniture making?

- Oil finishes are made from natural oils, such as linseed oil or tung oil.

- They penetrate into the wood and provide a durable, water-resistant finish.

- Varnish is a hard, clear finish that is made from resin and oil.

- It provides a high-gloss finish that is resistant to wear and tear.

- Lacquer is a clear finish that is made from nitrocellulose.

- It provides a durable, high-gloss finish that is resistant to scratches and chemicals.

4. What are the different types of wood stains used in furniture making?

- Water-based stains are made from water-soluble dyes.

- They are easy to apply and can be used to create a wide range of colors.

- Oil-based stains are made from oil-soluble dyes.

- They penetrate into the wood and provide a rich, durable finish.

- Gel stains are made from a combination of water-soluble and oil-soluble dyes.

- They have a thick, gel-like consistency that makes them easy to apply and control.

5. What are the different types of wood adhesives used in furniture making?

- Polyvinyl acetate (PVA) glue is a water-based adhesive that is commonly used in furniture making.

- It is easy to apply and provides a strong, durable bond.

- Epoxy glue is a two-part adhesive that is made from resin and hardener.

- It provides a very strong and durable bond that is resistant to water and chemicals.

- Cyanoacrylate glue (super glue) is a fast-acting adhesive that is used for bonding small pieces of wood.

- It provides a strong bond that is resistant to water and chemicals.

6. What are the different types of wood screws used in furniture making?

- Wood screws are used to join two pieces of wood together.

- They come in a variety of sizes and types, depending on the application.

- The most common type of wood screw is the flat head screw.

- It has a flat head that sits flush with the surface of the wood.

- Other types of wood screws include the round head screw, the oval head screw, and the hex head screw.

7. What are the different types of wood nails used in furniture making?

- Wood nails are used to join two pieces of wood together.

- They are made from a variety of materials, including steel, brass, and aluminum.

- The most common type of wood nail is the common nail.

- It has a pointed tip and a flat head.

- Other types of wood nails include the brad nail, the finishing nail, and the box nail.

8. What are the different types of wood tools used in furniture making?

- Hand saws are used to cut wood.

- They come in a variety of sizes and types, depending on the application.

- The most common type of hand saw is the crosscut saw.

- It has teeth that are designed to cut across the grain of the wood.

- Other types of hand saws include the rip saw, the coping saw, and the jigsaw.

9. What are the different types of power tools used in furniture making?

- Power tools are used to cut, shape, and join wood.

- They come in a variety of sizes and types, depending on the application.

- The most common type of power tool is the circular saw.

- It has a circular blade that is used to cut wood.

- Other types of power tools include the miter saw, the table saw, and the jointer.

10. What are the different types of measuring tools used in furniture making?

- Measuring tools are used to measure the length, width, and thickness of wood.

- They come in a variety of sizes and types, depending on the application.

- The most common type of measuring tool is the ruler.

- It has a straight edge that is used to measure the length of wood.

- Other types of measuring tools include the tape measure, the carpenter’s square, and the level.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembled Wood Products Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembled Wood Products Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assembled Wood Products Repairers are responsible for repairing and refinishing assembled wood products, such as furniture, cabinets, and doors. They may also be required to build new products from scratch. Some of the key job responsibilities of an Assembled Wood Products Repairer include:

1. Repairing damaged wood products

Repairers may need to fix cracks, dents, scratches, and other damage to wood products. They may also need to replace broken or missing parts.

- Inspecting damaged wood products to determine the extent of the damage

- Repairing cracks, dents, scratches, and other damage using a variety of tools and techniques

- Replacing broken or missing parts

2. Refinishing wood products

Repairers may also need to refinish wood products to restore their original appearance. This may involve sanding, staining, and painting or varnishing.

- Sanding wood products to remove old finish or smooth out rough surfaces

- Staining wood products to change their color or appearance

- Painting or varnishing wood products to protect them from damage and improve their appearance

3. Building new wood products

In some cases, repairers may also be required to build new wood products from scratch. This may involve cutting, shaping, and assembling wood pieces.

- Cutting wood pieces to size using a variety of tools

- Shaping wood pieces using a variety of tools

- Assembling wood pieces to create new products

4. Maintaining and cleaning work area

Repairers are also responsible for maintaining and cleaning their work area. This may involve sweeping, mopping, and dusting, as well as keeping tools and equipment in good condition.

- Maintaining and cleaning work area to ensure a safe and efficient work environment

- Keeping tools and equipment in good condition to minimize downtime and ensure quality repairs

Interview Tips

Interviewing for a job as an Assembled Wood Products Repairer can be a daunting task, but there are a few things you can do to prepare and increase your chances of success.

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn more about their history, mission, and products or services.

- Read online reviews of the company to get an idea of what it is like to work there.

- Check out the company’s social media pages to see what kind of content they post and how they interact with their followers.

- Look at the job description carefully and identify the key skills and experience that the employer is looking for.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Think about your strengths and weaknesses and how they relate to the job requirements.

- Prepare examples of your work experience that demonstrate the skills and experience that the employer is looking for.

- Be prepared to talk about your education and training.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the employer that you are serious about the job and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview a few minutes early so that you have time to check in and prepare yourself.

4. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and let your personality shine through.

- Be honest and open about your skills and experience.

- Be enthusiastic and positive about the job and the company.

- Ask questions at the end of the interview to show that you are interested and engaged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembled Wood Products Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!