Feeling lost in a sea of interview questions? Landed that dream interview for Assembling Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Assembling Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

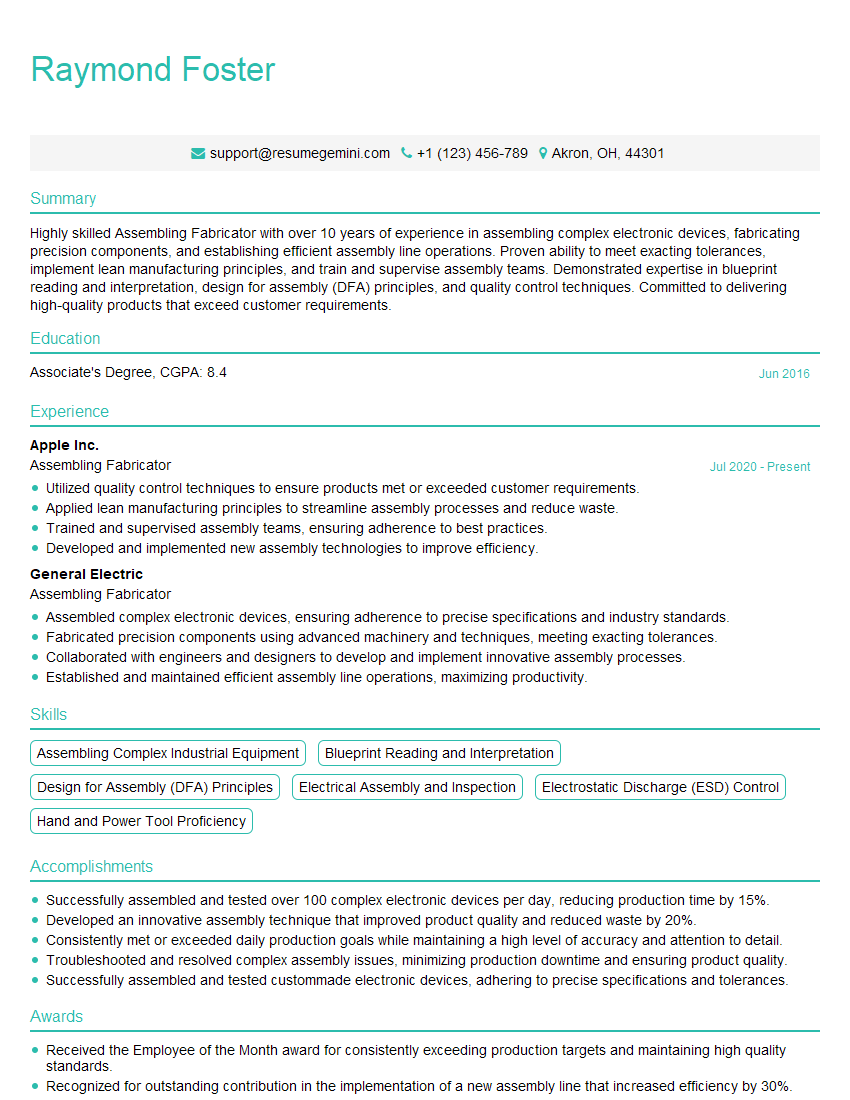

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembling Fabricator

1. What is the typical fabrication process for assembling metal components?

The typical fabrication process for assembling metal components involves several steps:

- Preparation: This includes cleaning and preparing the metal components, such as removing any rust or dirt.

- Cutting: The metal components are cut into the desired shapes and sizes using tools such as saws, shears, or lasers.

- Bending: The components are bent into the required shapes using bending machines or hand tools.

- Welding: The components are joined together using welding techniques such as MIG welding, TIG welding, or spot welding.

- Finishing: The assembled components may undergo finishing processes such as grinding, polishing, or painting to improve their appearance or durability.

2. What are the different types of welding techniques used in fabrication?

- MIG welding (Metal Inert Gas welding): It uses a continuously fed wire electrode and an inert gas shield to protect the weld from contamination.

- TIG welding (Tungsten Inert Gas welding): It uses a non-consumable tungsten electrode and an inert gas shield to provide a high-quality weld.

- Spot welding: It uses two copper electrodes to apply pressure and an electrical current to create localized welds.

- Arc welding: It uses an electric arc between an electrode and the metal to create the weld.

3. What are the common materials used in fabrication?

- Steel: It is a strong and durable material commonly used in fabrication, such as structural steel, stainless steel, or galvanized steel.

- Aluminum: It is a lightweight and corrosion-resistant material often used in aerospace, automotive, and marine applications.

- Copper: It is a good conductor of electricity and heat, making it suitable for electrical components and heat exchangers.

- Brass: It is an alloy of copper and zinc, providing strength and corrosion resistance, used in plumbing, musical instruments, and decorative applications.

- Plastic: It is a versatile material offering a wide range of properties, such as flexibility, durability, and resistance to chemicals or corrosion.

4. What are the common fabrication tools and equipment?

- Welding machines: These are used for welding metal components together.

- Cutting machines: These are used for cutting metal components into shapes and sizes.

- Bending machines: These are used for bending metal components into desired shapes.

- Grinders: These are used for smoothing and shaping metal surfaces.

- Measuring and layout tools: These are used for ensuring accuracy in fabrication.

- Safety equipment: This is essential for protecting fabricators from hazards.

5. What are the safety precautions to be taken while working with fabrication machinery?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Ensure that the equipment is properly grounded and maintained to prevent electrical hazards.

- Keep the work area clean and well-lit to prevent accidents.

- Follow proper operating procedures and avoid loose clothing or jewelry that could get caught in machinery.

- Be aware of the potential hazards associated with welding, such as fumes and arc flash.

6. What are the different types of assembly techniques used in fabrication?

- Mechanical assembly: It involves using fasteners such as bolts, nuts, and screws to connect components.

- Welding: It uses welding techniques to permanently join metal components.

- Adhesive bonding: It uses adhesives to bond components together, providing a strong and durable bond.

- Press fitting: It involves using pressure to fit components together, creating a tight and secure connection.

7. What are the quality control measures implemented during fabrication?

- Dimensional inspection: Ensuring components meet the specified dimensions and tolerances.

- Visual inspection: Checking for defects or imperfections on the surface of the fabricated parts.

- Non-destructive testing (NDT): Using techniques like ultrasonic testing or dye penetrant testing to detect internal defects.

- Material testing: Verifying the material properties and ensuring they meet the required specifications.

- Functional testing: Testing the assembled product to ensure it meets the desired performance criteria.

8. What are the challenges faced in assembly fabrication?

- Precision and accuracy: Ensuring components fit together precisely and meet specified tolerances.

- Material compatibility: Choosing materials that are compatible with each other and suitable for the intended application.

- Efficiency and productivity: Optimizing processes to minimize fabrication time and cost while maintaining quality.

- Safety: Implementing proper safety measures to protect workers from potential hazards.

- Quality control: Maintaining consistency in quality and meeting customer specifications.

9. What is the importance of following assembly drawings and specifications?

- Ensures accurate fabrication: Assembly drawings provide detailed instructions and specifications for fabricating components.

- Maintains consistency: Following specifications ensures that all components are fabricated to the same standards, resulting in a uniform and functional product.

- Prevents errors: Adhering to specifications minimizes the risk of errors and rework, saving time and resources.

- Facilitates communication: Assembly drawings serve as a common reference point for fabricators and assemblers, reducing miscommunications.

10. How do you stay up to date with the latest fabrication techniques and technologies?

- Attend industry events and conferences: These provide opportunities to learn about new technologies and best practices.

- Read industry publications and technical journals: They offer insights into current trends and advancements.

- Participate in online forums and discussion groups: These connect fabricators and allow for knowledge sharing.

- Seek training and certification: Completing courses and obtaining certifications demonstrates commitment to professional development.

- Collaborate with suppliers and manufacturers: They can provide information about new products and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembling Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembling Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assembling Fabricators are responsible for assembling and fabricating a variety of products, often using specialized tools and equipment. They work in a variety of industries, including automotive, aerospace, and construction. Some of the key job responsibilities of an Assembling Fabricator include:

1. Assembling products according to blueprints and specifications

Assembling Fabricators must be able to read and interpret blueprints and specifications in order to assemble products correctly. They must also be able to follow instructions and work independently.

- Assemble components and parts into finished products.

- Use hand tools and power tools to assemble and fabricate products.

2. Fabricating parts using a variety of materials

Assembling Fabricators may need to fabricate parts using a variety of materials, including metal, plastic, and wood. They must be able to use a variety of tools and equipment to fabricate parts to the required specifications.

- Fabricate parts using a variety of materials, such as metal, plastic, and wood.

- Use welding, soldering, and other fabrication techniques to create parts.

3. Inspecting products to ensure quality

Assembling Fabricators are responsible for inspecting products to ensure that they meet quality standards. They must be able to identify defects and take corrective action as necessary.

- Inspect products to ensure that they meet quality standards.

- Identify defects and take corrective action as necessary.

4. Maintaining a clean and safe work area

Assembling Fabricators must maintain a clean and safe work area to prevent accidents and injuries. They must also be able to follow safety procedures and regulations.

- Maintain a clean and safe work area.

- Follow safety procedures and regulations.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for an Assembling Fabricator position:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. You can research the company on their website, LinkedIn, and other online sources.

- Visit the company’s website to learn about their history, mission, and values.

- Check out the company’s LinkedIn page to see what employees are saying about the company.

- Read online reviews of the company to get a sense of the company’s culture and work environment.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- You can also practice answering questions specific to the Assembling Fabricator position, such as “What experience do you have in assembling and fabricating products?”.

- It is also helpful to prepare questions to ask the interviewer. This shows that you are interested in the position and the company.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in appropriate business attire.

- Arrive on time for your interview.

4. Be yourself and be enthusiastic

It is important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be yourself and let your personality shine through.

- Be yourself and be enthusiastic.

- The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembling Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!