Are you gearing up for an interview for a Assembly Cleaner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Assembly Cleaner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

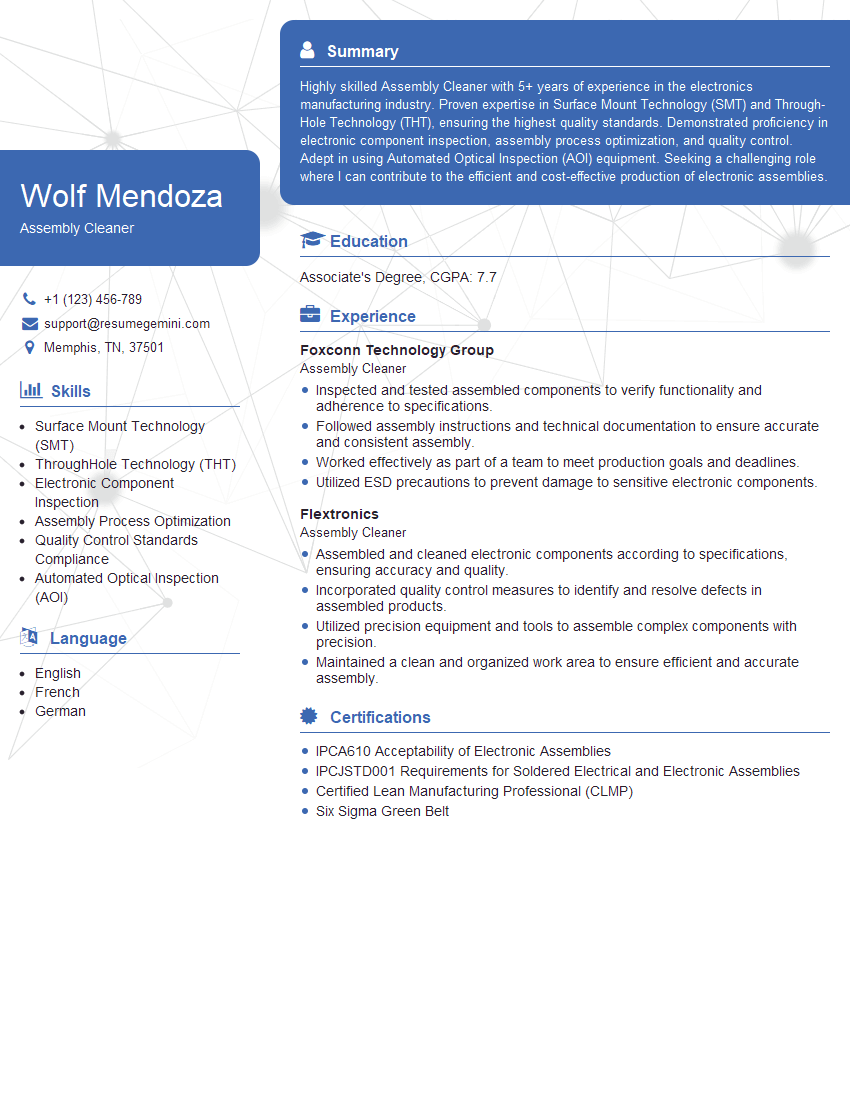

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Cleaner

1. What are the different cleaning methods you use for general cleaning of an assembly area?

In general cleaning of an assembly area, I follow a systematic approach to ensure thorough and effective cleaning. My methods include:

- Dry cleaning: Using a vacuum cleaner or compressed air to remove dust, dirt, and debris from surfaces.

- Wet cleaning: Using a mop or cloth dampened with a cleaning solution to wipe down surfaces and remove stains or spills.

- Disinfection: Using a disinfectant solution to kill bacteria and viruses on surfaces, ensuring a hygienic environment.

2. How do you ensure that the assembly area is kept free of contamination and particles?

Maintaining a Clean and Controlled Environment

- Regular cleaning: I adhere to a regular cleaning schedule to remove contaminants and prevent their accumulation.

- Controlling access: I restrict access to the assembly area to authorized personnel only, minimizing the risk of contamination.

Using Proper Cleaning Techniques

- Vacuuming: I use a HEPA filter vacuum cleaner to efficiently remove dust and particles from surfaces.

- Wiping and mopping: I use microfiber cloths and mops to effectively capture and remove contaminants.

3. What is your approach to cleaning delicate or sensitive components during assembly?

When handling delicate or sensitive components during assembly, I take utmost care to prevent damage:

- Soft and lint-free materials: I use soft, lint-free cloths or brushes to gently clean and remove contaminants.

- Specialized cleaning solutions: I employ specific cleaning solutions designed for sensitive materials, ensuring their integrity.

- Precision cleaning: I use precise and controlled movements to avoid applying excessive force or causing damage.

4. How do you handle the disposal of hazardous cleaning agents and waste materials?

I prioritize the safe and responsible disposal of hazardous cleaning agents and waste materials:

- Proper storage: I store hazardous materials in designated and well-ventilated areas, adhering to safety regulations.

- Neutralization: I neutralize certain cleaning agents before disposal, reducing their environmental impact.

- Collaboration with waste management: I work closely with authorized waste management companies to ensure proper disposal and recycling.

5. What is your understanding of electrostatic discharge (ESD) and how do you prevent it during assembly?

Electrostatic discharge (ESD) is a critical concern in assembly environments, and I take the following measures to prevent it:

- Grounding: I ensure that all equipment and work surfaces are properly grounded to dissipate static charges.

- Anti-static materials: I use anti-static mats, wrist straps, and clothing to minimize the accumulation of static electricity.

- Handling techniques: I handle components with care, avoiding direct contact with sensitive pins or connectors.

6. How do you stay updated with the latest cleaning techniques and industry best practices?

To stay abreast of the latest cleaning techniques and industry best practices, I engage in continuous learning:

- Training and workshops: I attend training sessions and workshops conducted by industry experts.

- Research and online resources: I actively seek knowledge through research papers, articles, and online forums.

- Collaboration with peers: I exchange ideas and experiences with colleagues and industry professionals.

7. What are your strengths and weaknesses as an Assembly Cleaner?

Strengths:

- Attention to detail: I am meticulous and thorough in my cleaning tasks, ensuring a spotless and contamination-free environment.

- Technical knowledge: I possess a strong understanding of cleaning techniques, materials, and safety protocols.

- Team player: I work effectively in a team environment, contributing to maintaining a clean and organized assembly area.

Weaknesses:

- Limited experience with certain specialized cleaning equipment: While I am proficient in a range of cleaning techniques, I may need additional training on specific equipment.

- Balancing multiple tasks: During peak cleaning periods, I may need to prioritize tasks to ensure efficient and timely completion.

8. Describe a situation where you had to troubleshoot a problem related to cleanliness in an assembly area.

In an assembly area, I encountered an issue with excessive dust accumulation. I traced the source to a faulty air filtration system. I promptly reported the issue and collaborated with maintenance personnel to resolve it. By identifying and addressing the root cause, I ensured the cleanliness and productivity of the assembly area.

9. How do you prioritize your cleaning tasks to ensure the most critical areas are addressed first?

I establish a cleaning priority based on the criticality of the assembly area and the potential impact of contamination. High-traffic areas, sensitive components, and areas prone to spills receive immediate attention. I also consider the production schedule to minimize disruption and ensure efficient cleaning.

10. What are your expectations and goals as an Assembly Cleaner in our company?

As an Assembly Cleaner in your esteemed organization, I aim to contribute to a pristine and efficient assembly environment. My goals include:

- Maintaining high cleaning standards: I am committed to exceeding expectations and ensuring the assembly area meets the highest standards of cleanliness.

- Continuous improvement: I believe in ongoing learning and improvement. I will actively seek opportunities to enhance my skills and contribute to the team’s success.

- Team collaboration: I am eager to collaborate with colleagues and support the overall goals of the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Assembly Cleaner is a crucial member of a production team, responsible for maintaining a clean and safe work environment. Their primary duties involve ensuring that assembly lines and equipment are spotless, thereby preventing contamination and ensuring efficient operations.

1. Cleaning and Maintenance

Maintaining a sanitary and well-organized work area is paramount. This includes:

- Sweeping, mopping, and vacuuming floors, work surfaces, and equipment

- Wiping down and disinfecting machinery, tools, and workstations

- Removing debris, spills, and waste materials promptly

2. Equipment Upkeep

Assembly Cleaners play a vital role in preventive maintenance:

- Lubricating moving parts and inspecting equipment for any signs of wear or damage

- Reporting any maintenance issues to supervisors promptly

- Assisting with minor repairs and adjustments under supervision

3. Quality Control

Ensuring product quality is an integral part of an Assembly Cleaner’s role:

- Inspecting parts and assemblies for cleanliness and adherence to specifications

- Identifying potential defects or contamination issues

- Taking corrective actions to prevent quality problems

4. Safety and Compliance

Assembly Cleaners are responsible for maintaining a safe and compliant work environment:

- Adhering to established safety protocols and regulations

- Wearing appropriate personal protective equipment (PPE)

- Maintaining hazardous materials in designated areas

- Properly disposing of waste and chemicals

Interview Preparation Tips

To ace an interview for an Assembly Cleaner position, candidates should thoroughly prepare and highlight their relevant skills and experience. Here are some interview preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific job requirements. This demonstrates your genuine interest and enthusiasm for the role.

2. Practice Common Interview Questions

Prepare for typical interview questions related to your experience, skills, and qualifications. Practice answering them concisely and effectively, emphasizing your strengths and how they align with the position.

3. Highlight Relevant Skills and Experience

Review the job description carefully and identify the key skills and experience required. Showcase your proficiency in these areas, providing specific examples and quantifying your accomplishments whenever possible.

4. Demonstrate Attention to Detail

Emphasize your meticulous nature and keen attention to detail, as it is crucial for maintaining a clean and organized assembly environment. Highlight instances where you have demonstrated these qualities in previous roles.

5. Ask Meaningful Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your engagement, interest, and desire to learn more about the company and the position.

6. Maintain a Positive Attitude

Throughout the interview, maintain a professional and positive demeanor. Be confident in your abilities, but also be humble and eager to learn. A positive attitude can leave a lasting impression on the interviewer.

7. Dress Appropriately

First impressions matter, so make sure to dress professionally for the interview. Choose clothing that is clean, ironed, and suitable for the industrial or manufacturing setting.

8. Be Punctual

Arrive for the interview on time, demonstrating your punctuality and respect for the interviewer’s time. Being late can reflect poorly on your professionalism.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembly Cleaner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.