Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Assembly Lead Person interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Assembly Lead Person so you can tailor your answers to impress potential employers.

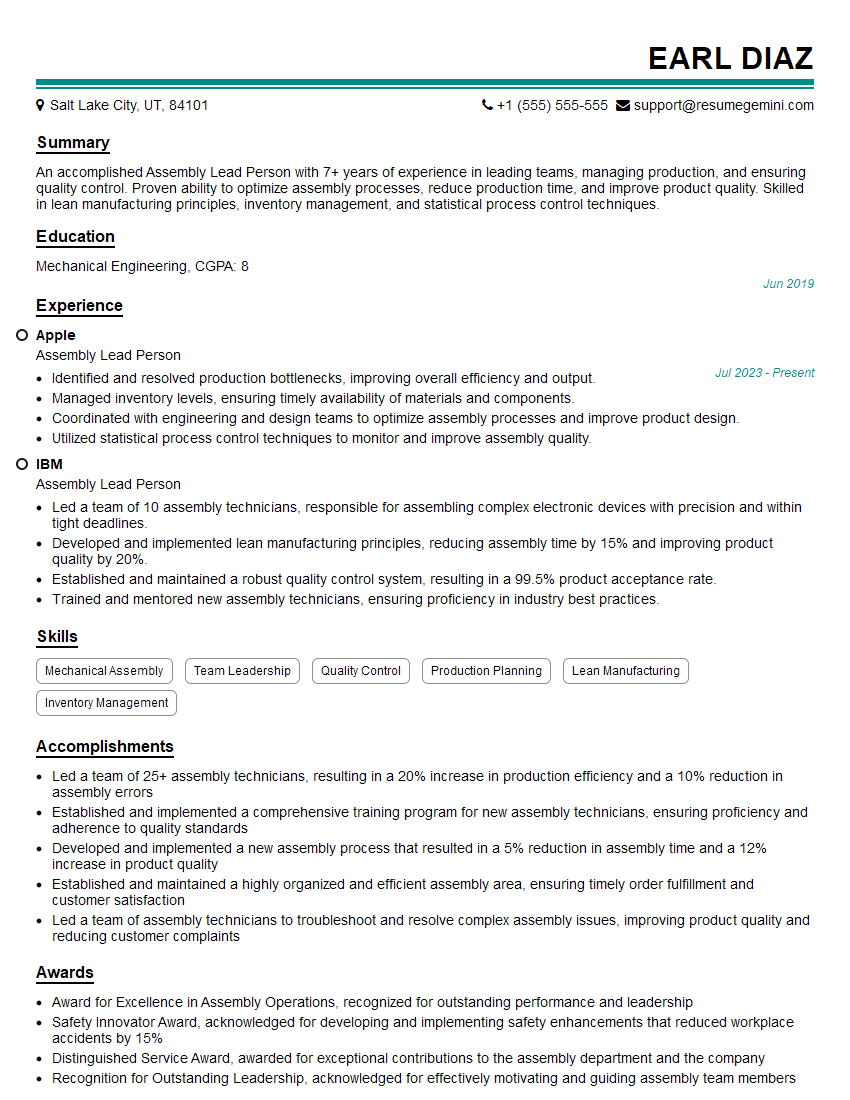

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Lead Person

1. What are the key responsibilities of an Assembly Lead Person?

The key responsibilities of an Assembly Lead Person typically include:

- Supervising and leading a team of assembly workers

- Ensuring that all assembly operations are carried out efficiently and according to quality standards

- Monitoring production output and identifying and resolving any bottlenecks or issues

- Providing training and support to assembly workers

- Maintaining a safe and organized work environment

2. What are the different types of assembly processes?

Manual assembly

- Involves the manual assembly of components by workers using hand tools

- Requires attention to detail and precision

Automated assembly

- Involves the use of machines and robots to assemble components

- Requires programming and maintenance skills

Semi-automated assembly

- Combines manual and automated assembly processes

- Requires a balance of technical and manual skills

3. What are the different types of assembly tools and equipment?

Various assembly tools and equipment are used in the industry, including:

- Hand tools (e.g., screwdrivers, wrenches, pliers)

- Power tools (e.g., drills, sanders, grinders)

- Assembly machines (e.g., conveyor systems, robots)

- Testing equipment (e.g., gauges, calipers, torque testers)

- Safety equipment (e.g., goggles, gloves, earplugs)

4. What are the key quality control measures in assembly operations?

Key quality control measures in assembly operations include:

- Visual inspections

- Dimensional measurements

- Functional testing

- Statistical process control

- Continuous improvement initiatives

5. What are the different types of assembly defects?

Common types of assembly defects include:

- Incorrect assembly sequence

- Missing or incorrect components

- Loose or overtightened fasteners

- Misalignment of components

- Damage to components or assemblies

6. How do you handle assembly defects?

When assembly defects are identified, it is important to:

- Identify the root cause of the defect

- Take corrective action to prevent the defect from recurring

- Document the defect and any corrective actions taken

- Communicate with relevant parties (e.g., customers, suppliers)

7. What are the key safety considerations in assembly operations?

Key safety considerations in assembly operations include:

- Proper use of tools and equipment

- Safe handling of materials

- Maintaining a clean and organized work environment

- Wearing appropriate personal protective equipment

- Following established safety procedures

8. How do you motivate and engage your assembly team?

To motivate and engage an assembly team, it is important to:

- Set clear goals and expectations

- Provide regular feedback and recognition

- Foster a positive and collaborative work environment

- Empower team members to make decisions

- Celebrate successes as a team

9. How do you stay up-to-date on the latest assembly technologies and best practices?

To stay up-to-date on the latest assembly technologies and best practices, it is important to:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Participate in online forums and discussion groups

- Network with other professionals in the field

10. How do you manage production schedules and ensure that deadlines are met?

To manage production schedules and ensure that deadlines are met, it is important to:

- Create and maintain a realistic production schedule

- Monitor progress against the schedule regularly

- Identify and address potential bottlenecks

- Communicate with relevant parties (e.g., suppliers, customers)

- Take corrective action when necessary

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Lead Person.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Lead Person‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Assembly Lead Person plays a crucial role in leading and supervising the assembly process, ensuring the smooth and efficient production of products. Their key responsibilities typically include:

1. Team Management

Leading and motivating a team of assembly workers, assigning tasks, and providing guidance and support.

- Establishing clear expectations and goals for the team.

- Monitoring performance and providing feedback to improve productivity.

2. Product Assembly Supervision

Overseeing the assembly process, ensuring that products meet specifications and quality standards.

- Identifying and resolving assembly issues promptly.

- Implementing process improvements to enhance efficiency and accuracy.

3. Quality Control Management

Enforcing quality control procedures to maintain product standards.

- Conducting inspections and audits to identify defects.

- Working with suppliers to resolve quality-related concerns.

4. Production Planning and Scheduling

Planning and scheduling assembly workloads to meet production targets.

- Coordinating with other departments to ensure timely delivery.

- Monitoring inventory levels and placing orders for necessary components.

Interview Tips

To ace an interview for an Assembly Lead Person position, it’s crucial to demonstrate your leadership skills, technical knowledge, and commitment to quality. Here are some tips to help you prepare and impress the interviewer:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and specific role you’re applying for. This will help you understand their business objectives and how your skills and experience align with their needs.

- Visit the company’s website and social media pages.

- Review industry news and publications to stay updated on trends.

2. Highlight Your Leadership Capabilities

Emphasize your ability to lead and motivate a team effectively. Provide specific examples of how you have successfully managed teams, resolved conflicts, and fostered a positive and productive work environment.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Quantify your achievements whenever possible to demonstrate the impact of your leadership.

3. Showcase Your Technical Expertise

Demonstrate your understanding of assembly processes, quality control techniques, and production planning principles. Discuss your experience with specific tools, equipment, and software used in assembly operations.

- Highlight your knowledge of industry best practices and standards.

- Share examples of process improvements you have implemented.

4. Emphasize Your Commitment to Quality

Stress your dedication to delivering high-quality products. Explain your experience in implementing and maintaining quality control systems. Discuss your attention to detail and commitment to meeting customer specifications.

- Share examples of how you have identified and resolved quality issues.

- Explain your understanding of quality management principles, such as ISO 9001.

5. Practice Your Answers

Take the time to prepare and practice your answers to common interview questions. Anticipate questions related to your leadership style, technical skills, and approach to quality control. Prepare concise and articulate responses that highlight your strengths and qualifications.

- Consider using a mock interview with a friend or family member to gain feedback.

- Record yourself answering questions to identify areas for improvement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Assembly Lead Person role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.