Are you gearing up for an interview for a Assembly Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Assembly Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

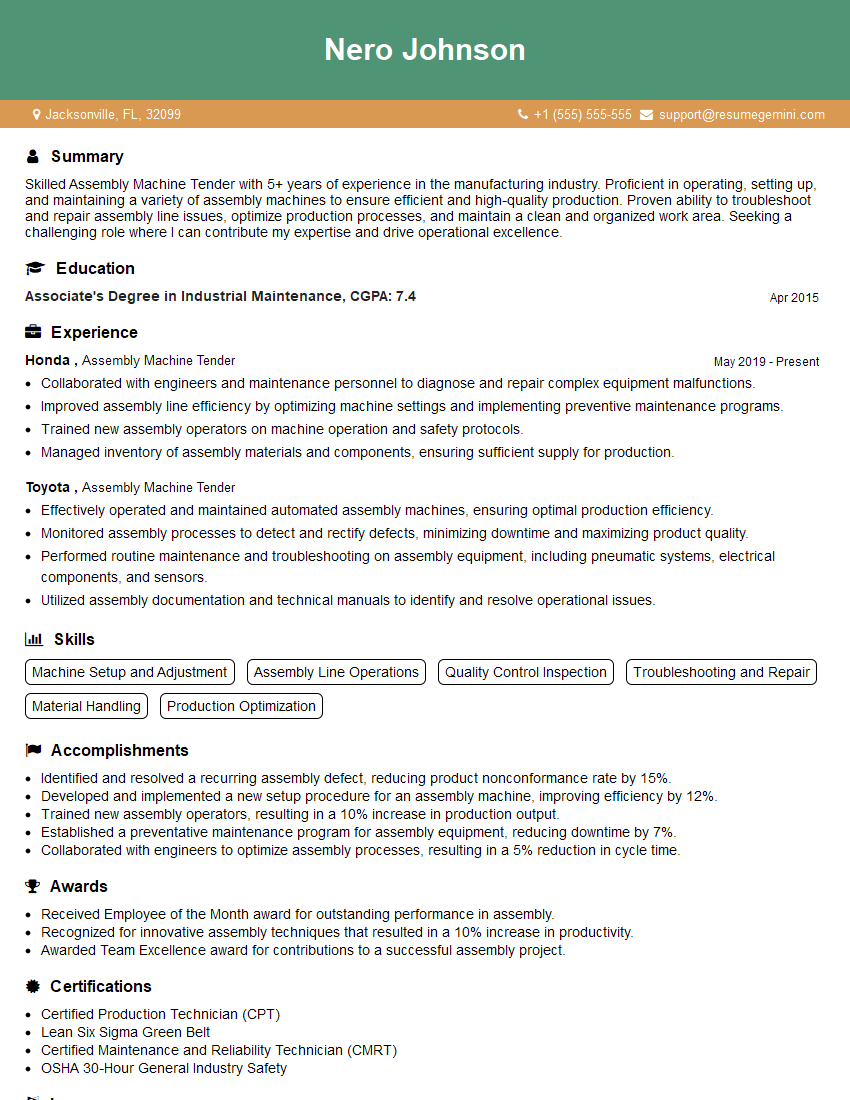

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Machine Tender

1. Describe your experience in operating and maintaining assembly machines.

In my previous role as an Assembly Machine Tender, I was responsible for operating and maintaining a variety of assembly machines, including automated assembly lines, conveyors, and robotic welding equipment. I have a deep understanding of the principles of assembly machine operation, including machine setup, configuration, and troubleshooting. Additionally, I am proficient in performing preventive maintenance and repairs to ensure optimal machine performance.

2. What are the key safety procedures that you follow when working with assembly machines?

Adhering to Safety Regulations

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Follow established lockout/tagout procedures to prevent accidental machine startups.

- Inspect machines regularly for potential hazards and report any identified issues promptly.

Observing Safe Work Practices

- Maintain a clean and organized work area to minimize tripping hazards and potential spills.

- Be aware of moving machine parts and keep hands clear of danger zones.

- Never operate machines without proper training and authorization.

3. Can you explain the process of setting up and calibrating an assembly machine?

The process of setting up and calibrating an assembly machine typically involves the following steps:

- Preparation: Gather necessary tools, materials, and documentation.

- Machine Setup: Position the machine in the designated area, connect necessary utilities, and mount tooling and fixtures.

- Parameter Configuration: Enter machine parameters, such as cycle time, pressure settings, and feed rates, based on the assembly specifications.

- Calibration: Use precision measuring tools and gauges to verify that the machine is operating within specified tolerances.

- Test Run: Perform a test run to ensure that the machine is functioning correctly and producing acceptable parts.

4. How do you handle machine breakdowns and minimize downtime?

When a machine breaks down, I follow a systematic approach to minimize downtime:

- Immediate Response: Secure the machine, isolate the problem, and notify the supervisor.

- Troubleshooting: Use diagnostic tools and procedures to identify the root cause of the issue.

- Repair: Perform necessary repairs or replacements using appropriate tools and techniques.

- Testing and Verification: Thoroughly test the machine after repairs to ensure it is operating correctly.

- Documentation: Record the breakdown, troubleshooting process, and repair actions for future reference.

5. What techniques do you use to improve the efficiency and productivity of assembly machines?

To enhance machine efficiency and productivity, I employ the following techniques:

- Process Optimization: Analyze machine operations and identify areas for improvement, such as reducing cycle time or minimizing material waste.

- Preventive Maintenance: Regularly perform maintenance tasks, such as cleaning, lubrication, and part replacement, to prevent breakdowns and extend machine lifespan.

- Operator Training: Provide training to operators on proper machine setup, operation, and maintenance techniques to minimize errors and improve efficiency.

- Automation: Explore opportunities to automate processes, such as material handling or data entry, to reduce manual intervention and increase productivity.

6. How do you ensure the quality of assembled products?

To ensure product quality, I implement the following measures:

- Visual Inspection: Regularly inspect assembled products for defects, such as missing components or misalignments.

- Dimensional Verification: Use measuring tools to verify that assembled products meet specified dimensions and tolerances.

- Functional Testing: For assemblies involving electrical or mechanical components, I perform functional tests to ensure proper operation and performance.

- Process Monitoring: Continuously monitor assembly processes to identify any deviations from established quality standards and take corrective actions as needed.

7. Tell me about your experience in working with automated assembly systems.

In my previous role, I worked extensively with automated assembly systems, including programmable logic controllers (PLCs) and robotic arms. I am proficient in programming PLCs to control machine sequences, monitor sensors, and perform automated quality checks. Additionally, I have experience in operating and maintaining robotic arms used for precision assembly tasks.

8. Describe a challenging assembly project you worked on and how you overcame the difficulties.

One challenging project I worked on involved assembling a complex electronic device with numerous small components. To overcome the difficulty, I carefully analyzed the assembly process and identified areas for improvement. I implemented a series of modifications to the assembly line, including automated component placement and improved operator ergonomics. As a result, we significantly reduced assembly time and improved product quality.

9. What are your strengths and weaknesses as an Assembly Machine Tender?

Strengths:

- Proficient in operating and maintaining various assembly machines

- Strong understanding of assembly principles and quality control techniques

- Excellent troubleshooting and problem-solving skills

- Ability to work independently and as part of a team

- Committed to safety and continuous improvement

Weaknesses:

- Limited experience with certain specialized assembly equipment (can be addressed through training)

- Working extended hours can sometimes be physically demanding

10. Why are you interested in working as an Assembly Machine Tender for our company?

I am eager to join your company as an Assembly Machine Tender because I am impressed by your reputation as a leader in the industry. Your commitment to innovation and quality aligns with my own professional goals. I believe that my skills and experience would make me a valuable asset to your team, and I am confident that I can contribute to the success of your assembly operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assembly Machine Tenders are responsible for operating and maintaining assembly machines. They ensure that the machines are running smoothly and that the products being assembled are meeting quality standards. Some of the key job responsibilities of an Assembly Machine Tender include:

1. Operating and monitoring assembly machines

Assembly Machine Tenders are responsible for operating and monitoring assembly machines. This involves setting up the machines, loading the materials, and starting the production process. They also monitor the machines during operation to ensure that they are running smoothly and that the products being assembled are meeting quality standards.

2. Inspecting finished products

Assembly Machine Tenders are responsible for inspecting finished products to ensure that they meet quality standards. This involves checking the products for defects, such as scratches, dents, or missing parts. They also check the products to ensure that they are assembled correctly and that all of the components are functioning properly.

3. Troubleshooting and repairing assembly machines

Assembly Machine Tenders are responsible for troubleshooting and repairing assembly machines. This involves identifying the source of the problem and making the necessary repairs. They also perform preventive maintenance on the machines to prevent problems from occurring in the future.

4. Maintaining a clean and organized work area

Assembly Machine Tenders are responsible for maintaining a clean and organized work area. This involves keeping the work area free of debris, such as scrap materials and tools. They also keep the machines clean and lubricated to ensure that they are operating properly.

Interview Tips

To prepare for an interview for an Assembly Machine Tender position, it is important to have a strong understanding of the key job responsibilities. You should also be prepared to answer questions about your experience operating and maintaining assembly machines. Here are some tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. You can find information about the company on their website, social media pages, and Glassdoor. You can also find information about the position in the job description.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. You can also prepare for questions about your experience operating and maintaining assembly machines by reviewing your resume and highlighting your relevant skills and experience.

3. Be prepared to talk about your experience and skills

In addition to answering common interview questions, you will also be asked to talk about your experience and skills. Be sure to highlight your experience operating and maintaining assembly machines, as well as any other relevant skills and experience that you have. You can also talk about your problem-solving skills, your attention to detail, and your ability to work independently.

4. Be enthusiastic and positive

It is important to be enthusiastic and positive during your interview. This will show the interviewer that you are interested in the position and that you are confident in your abilities. Be sure to make eye contact with the interviewer, smile, and speak clearly and confidently. You should also be prepared to answer questions about your availability and your salary expectations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembly Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!