Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Assembly Riveter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

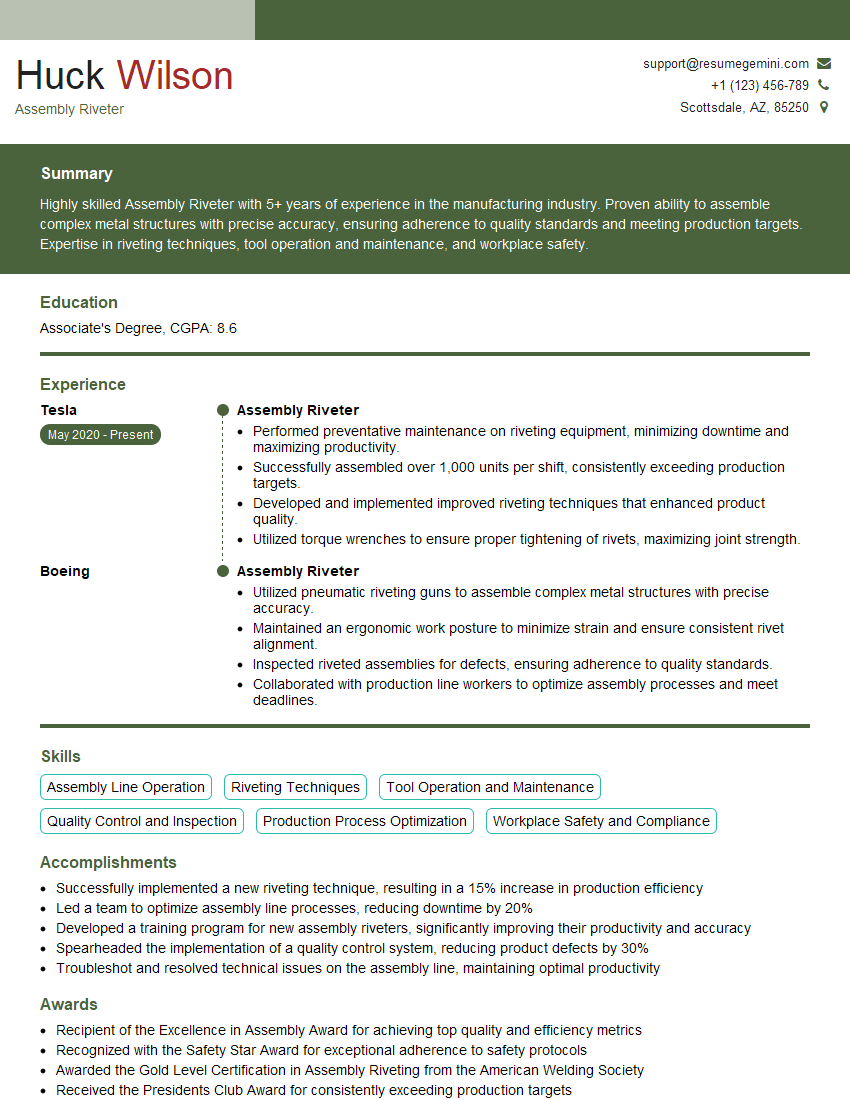

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Riveter

1. Explain the assembly process of riveting in detail.

- Identify the materials and tools required for the assembly process.

- Describe the steps involved in preparing the components for riveting.

- Explain the techniques used for applying rivets to the components.

- Discuss the importance of quality control during the assembly process.

2. What types of rivets are commonly used in assembly and what are their applications?

- Solid Rivets

- Blind Rivets

- Self-Piercing Rivets

- Aircraft Manufacturing

- Automotive Industry

- Construction

Types of Rivets:

Applications:

3. Describe the different types of riveting machines and their advantages and disadvantages.

- Pneumatic Riveting Machines

- Hydraulic Riveting Machines

- Electric Riveting Machines

- Pneumatic: Powerful, portable, but noisy.

- Hydraulic: Precise, but bulky and expensive.

- Electric: Compact, quiet, but limited power.

Types of Riveting Machines:

Advantages and Disadvantages:

4. How do you ensure the quality of rivets and their installation?

- Inspect rivets for defects (e.g., cracks, burrs).

- Verify rivet dimensions meet specifications.

- Set and maintain proper riveting machine parameters (e.g., force, time).

- Conduct visual inspections and perform pull tests to ensure rivet integrity.

- Monitor the assembly process and make adjustments as needed.

5. Explain the importance of proper rivet spacing and why it should be maintained during assembly.

- Ensures uniform strength and load distribution.

- Prevents excessive stress concentration and potential failures.

- Facilitates proper clinching and ensures reliable joint integrity.

- Adheres to engineering specifications and design requirements.

- Maintains structural integrity and reliability of the assembly.

6. Describe the safety precautions you take when operating riveting machines and handling rivets.

- Wear appropriate safety gear (e.g., eye protection, gloves).

- Ensure the machine is properly grounded.

- Inspect tools and machinery regularly.

- Use proper handling techniques to avoid injuries.

- Follow established safety protocols and procedures.

7. How do you troubleshoot common riveting problems, such as loose or misaligned rivets?

- Check rivet size and type.

- Adjust riveting machine settings.

- Ensure proper alignment of components.

- Check riveting machine settings.

- Inspect materials for defects.

- Clean riveting tools and machinery.

Loose Rivets:

Misaligned Rivets:

General Troubleshooting:

8. Explain the role of adhesives in riveting and when they are used in the assembly process.

- Enhance joint strength and fatigue resistance.

- Seal joints and prevent corrosion.

- Used in conjunction with rivets to provide additional bonding.

- Applied before or after riveting, depending on the specific application.

- Follow manufacturer’s instructions for proper usage and curing time.

9. Describe the techniques used for removing rivets from an assembly.

- Drill out the rivet head.

- Use a center punch to drive the rivet out.

- Drill out the rivet head.

- Use a rivet removal tool to pull the rivet out.

Manual Removal:

Mechanical Removal:

10. How do you maintain and calibrate riveting machines to ensure their accuracy and efficiency?

- Follow manufacturer’s maintenance instructions.

- Lubricate machine components regularly.

- Inspect and replace worn parts as needed.

- Calibrate the machine using traceable standards.

- Maintain records of maintenance and calibration activities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Riveter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Riveter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Assembly Riveter is responsible for assembling and riveting various components of aircraft, vehicles, and other products. They work in a fast-paced environment, often meeting strict deadlines. Some of their key responsibilities include:

1. Assemble components

The Assembly Riveter will need to assemble various components according to blueprints and specifications. This may involve attaching parts using rivets, bolts, or other fasteners.

- Read and interpret blueprints and specifications

- Assemble components according to specifications

- Inspect assembled components for accuracy

2. Rivet components

The Assembly Riveter will need to rivet components together to create a strong and durable bond. This process involves using a riveting gun to insert rivets into holes in the components.

- Select the correct rivet size and type

- Insert rivets into holes in components

- Use a riveting gun to set rivets

- Inspect riveted joints for strength and durability

3. Inspect assembled products

The Assembly Riveter will need to inspect assembled products to ensure that they meet quality standards. This may involve checking for defects, such as loose rivets or misaligned components.

- Inspect assembled products for defects

- Identify and correct any defects

- Maintain a clean and organized work area

4. Maintain equipment

The Assembly Riveter will need to maintain their equipment to ensure that it is in good working order. This may involve cleaning and lubricating the equipment, as well as making minor repairs.

- Clean and lubricate equipment

- Make minor repairs to equipment

- Calibrate equipment to ensure accuracy

Interview Tips

To ace the interview for an Assembly Riveter position, there are a few things you can do to prepare:

1. Research the company and the position

- Learn about the company’s history, products, and services

- Read the job description carefully and identify the key requirements

2. Practice your answers to common interview questions

- Prepare answers to questions about your experience, skills, and qualifications

- Practice your answers out loud so that you can deliver them confidently

3. Dress professionally and arrive on time for your interview

- First impressions matter, so make sure you dress appropriately and arrive on time

- This will show the interviewer that you are serious about the position

4. Be enthusiastic and engaged during your interview

- Show the interviewer that you are interested in the position and that you are eager to learn more about the company

- Ask questions about the company, the position, and the industry

5. Follow up after your interview

- Send a thank-you note to the interviewer within 24 hours

- In your note, reiterate your interest in the position and thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembly Riveter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!