Are you gearing up for an interview for a Assembly Stock Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Assembly Stock Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

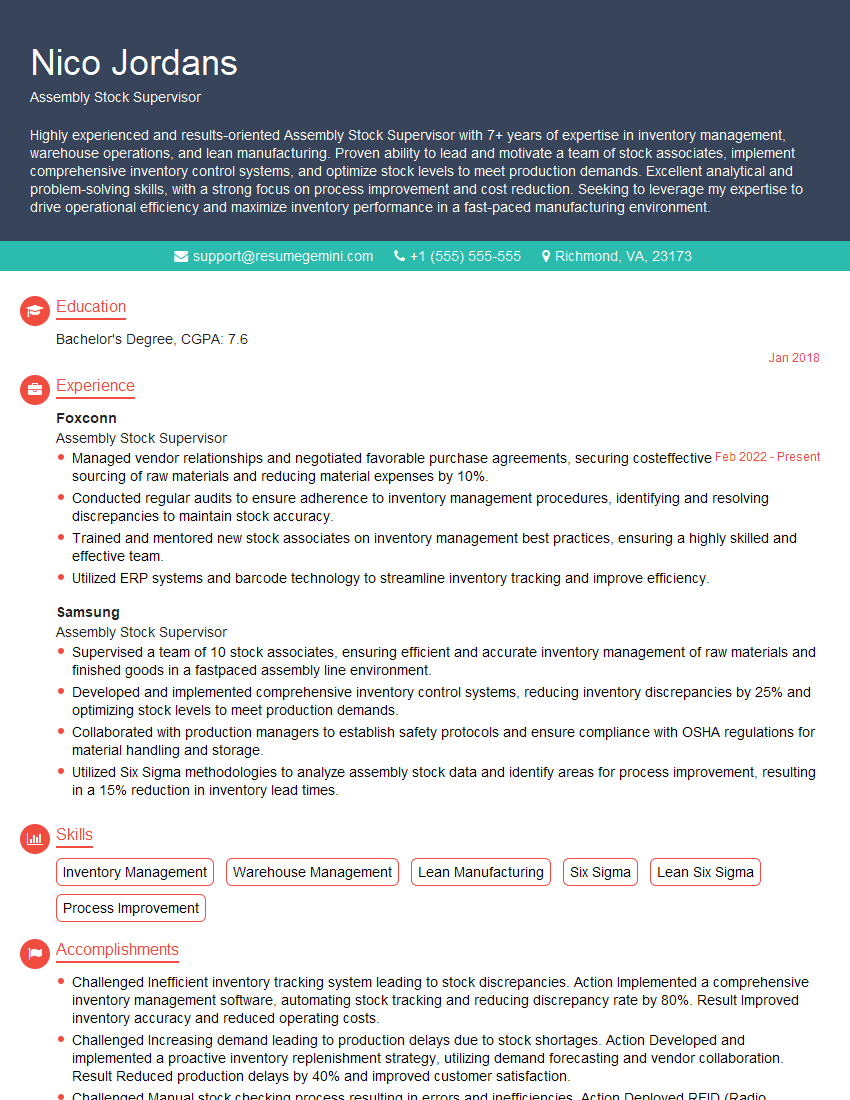

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assembly Stock Supervisor

1. Explain the role and responsibilities of an Assembly Stock Supervisor?

As an Assembly Stock Supervisor, my primary responsibilities would encompass:

- Overseeing all aspects of assembly stock management, ensuring efficient and accurate inventory control.

- Establishing and implementing stock replenishment strategies to maintain optimal inventory levels.

- Collaborating with assembly teams to identify stock requirements and prioritize urgent orders.

- Managing stock movement, including receiving, storing, and issuing materials to assembly lines.

- Conducting stock audits, reconciling discrepancies, and investigating any inventory variances.

2. Describe the key performance indicators (KPIs) you would track to measure the effectiveness of your stock management?

Inventory accuracy:

The percentage of stock items that are correctly recorded and accounted for in the inventory system.Stock turnover rate:

The number of times inventory is sold and replaced within a given period.Fill rate:

The percentage of customer orders that are fulfilled from stock without any backorders.Lead time:

The average time it takes to receive stock items from suppliers.Inventory carrying costs:

The total cost of holding inventory, including storage, insurance, and obsolescence.

3. How do you manage stock levels to prevent both overstocking and understocking?

To optimize stock levels, I employ a comprehensive approach that combines:

Demand forecasting:

Using historical data and industry trends to predict future demand for stock items.Safety stock management:

Maintaining a buffer of stock to cover unexpected fluctuations in demand or supply.Supplier lead time management:

Establishing clear lead times with suppliers to ensure timely delivery of stock items.Economic order quantity (EOQ) calculations:

Determining the optimal quantity to order each time to minimize total inventory costs.Just-in-time (JIT) inventory management:

Ordering stock items only when they are needed to reduce inventory carrying costs.

4. How do you ensure the quality of stock items and prevent the use of defective materials in assembly?

To guarantee stock quality and prevent assembly disruptions, I implement the following measures:

Supplier evaluation and qualification:

Assessing suppliers’ quality control processes and selecting those that meet our standards.Incoming inspection:

Inspecting all incoming stock items against defined quality specifications.Stock rotation:

Implementing a first-in, first-out (FIFO) system to ensure that the oldest stock items are used first.Quality assurance checks:

Conducting random quality checks on stock items throughout the storage period.Supplier collaboration:

Working closely with suppliers to resolve any quality issues and improve processes.

5. How do you handle stock discrepancies and investigate inventory variances?

When stock discrepancies or inventory variances occur, I follow a systematic approach to investigate and resolve them:

Physical inventory counts:

Conducting manual counts to verify the accuracy of inventory records.Transaction analysis:

Reviewing all stock transactions to identify any errors or unauthorized usage.Supplier reconciliation:

Comparing stock records with supplier invoices and delivery notes.Root cause analysis:

Identifying the underlying causes of discrepancies and implementing corrective actions.Loss prevention measures:

Enhancing security and implementing controls to prevent theft or unauthorized stock usage.

6. How do you leverage technology to improve stock management processes?

I embrace technology to streamline stock management operations:

Inventory management software:

Utilizing software to track stock levels, manage replenishment, and generate reports.Barcode scanning and RFID technology:

Automating stock tracking and reducing errors in receiving, storage, and issuing.Data analytics:

Analyzing inventory data to identify trends, optimize stock levels, and improve forecasting accuracy.Mobile inventory management:

Empowering staff with mobile devices to access stock information and perform tasks on the go.Electronic data interchange (EDI):

Exchanging data with suppliers and customers electronically to enhance communication and reduce paperwork.

7. How do you manage a team of stock personnel and ensure their productivity and job satisfaction?

Clear communication:

Establishing clear roles, responsibilities, and expectations for team members.Training and development:

Providing ongoing training to enhance team members’ skills and knowledge.Motivation and recognition:

Recognizing and rewarding team members for their contributions and achievements.Empowerment:

Delegating responsibilities and giving team members autonomy to make decisions.Team collaboration:

Fostering a collaborative environment where team members share ideas and support each other.

8. How do you stay updated on industry best practices and advancements in stock management?

Attending industry conferences and workshops:

Networking and learning from experts in the field.Reading industry publications and research papers:

Keeping abreast of the latest trends and methodologies.Consulting with peers and mentors:

Seeking advice and insights from experienced professionals.Participating in online forums and webinars:

Engaging in discussions and learning from others.Experimenting with new technologies and techniques:

Continuously evaluating and implementing innovative solutions.

9. How do you ensure compliance with regulatory requirements and industry standards related to stock management?

To maintain compliance, I adhere to the following measures:

Regular audits:

Conducting internal audits to assess compliance and identify areas for improvement.Documentation:

Maintaining accurate records of all stock transactions and inventory movements.Training:

Educating staff on regulatory requirements and industry best practices.Supplier management:

Ensuring that suppliers comply with relevant regulations and standards.Continuous improvement:

Regularly reviewing and updating processes to ensure ongoing compliance.

10. Describe a challenging situation you faced in stock management and how you overcame it.

During a period of high demand, our inventory levels were critically low, and we were facing the risk of production delays. I implemented the following strategies to overcome this challenge:

Supplier negotiation:

I negotiated with suppliers to expedite deliveries and increase order quantities.Emergency procurement:

I sourced stock items from alternative suppliers to supplement our primary supply chain.Inventory optimization:

I analyzed inventory data to identify non-critical stock items that could be temporarily replaced or reduced.Cross-functional collaboration:

I worked closely with assembly teams to prioritize urgent orders and adjust production schedules.Communication:

I kept management and stakeholders informed of the situation and provided regular updates on progress.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assembly Stock Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assembly Stock Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Assembly Stock Supervisors play a crucial role in ensuring the smooth functioning of assembly operations involving inventory management. Their primary responsibilities include:

1. Inventory Management

Efficiently managing stock levels by monitoring inventory, forecasting demand, and placing orders for materials and parts required for assembly.

- Maintaining accurate records of inventory levels and transactions.

- Implementing inventory control systems to optimize stock utilization and minimize waste.

2. Material Handling

Supervising the receipt, storage, and distribution of materials and parts within the assembly area.

- Verifying incoming materials against purchase orders and specifications.

- Ensuring proper storage and handling of materials to prevent damage or spoilage.

3. Production Support

Providing timely and accurate supply of materials and parts to assembly lines to maintain production schedules.

- Coordinating with production supervisors to understand production requirements and adjust inventory accordingly.

- Identifying and resolving any material shortages or quality issues that may impact production.

4. Quality Control

Inspecting materials and parts to ensure they meet quality standards before issuing them for assembly.

- Adhering to established quality control procedures to ensure the integrity of incoming materials.

- Identifying and segregating defective materials to prevent their use in assembly.

5. Team Management

Leading and motivating a team of stock associates and ensuring their adherence to safety and inventory management protocols.

- Providing training and guidance to team members on stock management practices and procedures.

- Maintaining a safe and organized work environment for the inventory team.

Interview Tips

To prepare for an Assembly Stock Supervisor interview, it is essential to research the company and the specific role, and practice answering common interview questions.

1. Tell me about your inventory management experience.

Be prepared to discuss your experience managing inventory in previous roles, including your knowledge of inventory control systems and techniques.

- Highlight your ability to optimize stock levels, reduce waste, and ensure the availability of materials for production.

- Share specific examples of how you implemented inventory management practices that improved efficiency and cost-effectiveness.

2. How do you handle material shortages or quality issues?

Describe your approach to resolving material shortages and quality issues, including your communication and problem-solving skills.

- Explain how you identify and prioritize material shortages, and your steps for finding alternative suppliers or expediting deliveries.

- Discuss your processes for isolating defective materials, communicating with suppliers, and ensuring that only quality materials are used in production.

3. How do you motivate and lead a team?

Share your experience leading and motivating teams, emphasizing your ability to provide training, delegate tasks, and foster a positive work environment.

- Describe how you set clear goals and expectations for your team, and how you provide feedback and support.

- Discuss your strategies for building a team culture that promotes safety, efficiency, and collaboration.

4. What is your understanding of quality control standards?

Explain your knowledge of quality control standards and procedures, and how you ensure the quality of incoming materials and parts.

- Discuss your experience with quality inspections, adherence to specifications, and documentation of quality checks.

- Share examples of how you have identified and resolved quality issues in previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Assembly Stock Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!