Are you gearing up for an interview for a Assistant Offset Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Assistant Offset Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

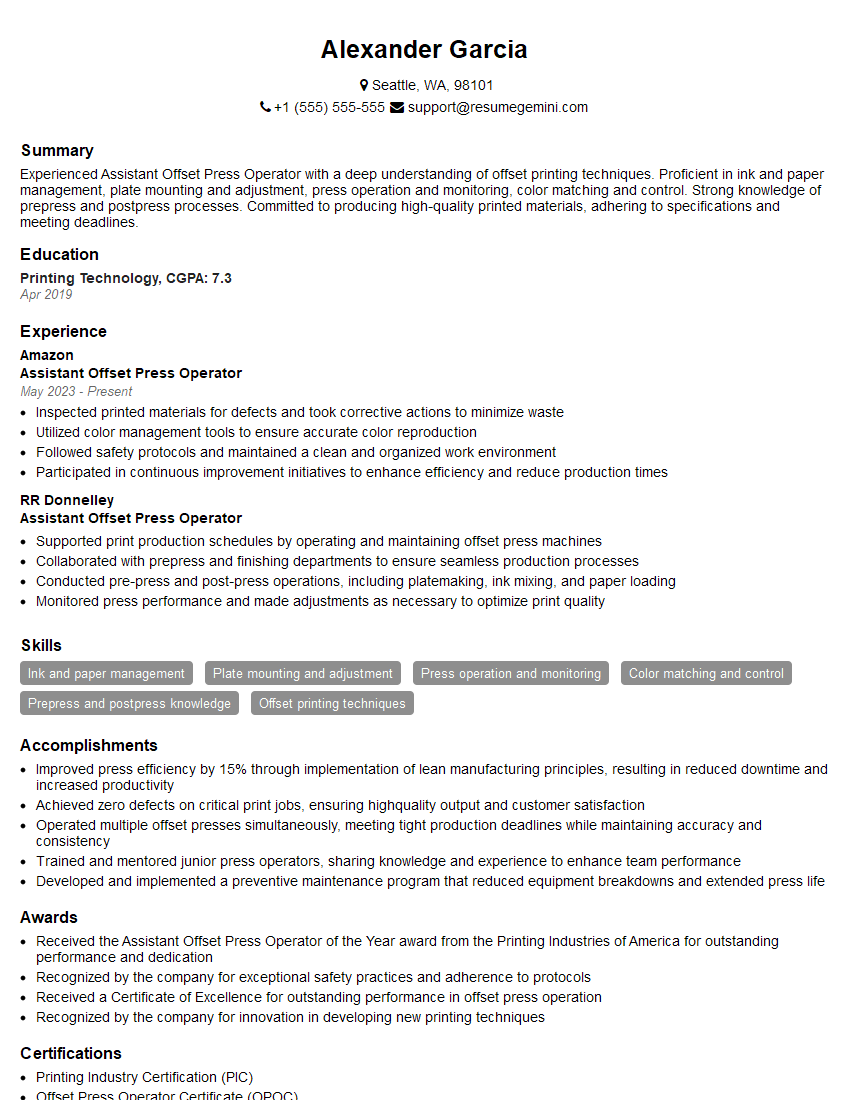

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Assistant Offset Press Operator

1. Explain the process of platemaking in offset printing?

Platemaking in offset printing involves creating a metal plate with the desired image or text to be printed. The process includes several steps:

- Generating a Digital Image: The original image or text is converted into a digital format using a computer and design software.

- Creating a Photomask: A photomask is a transparent film with the image or text burned onto it using a laser or light source.

- Exposing the Plate: The photomask is placed over a photosensitive metal plate, and ultraviolet light is shone through it, exposing the areas of the plate that correspond to the image.

- Developing the Plate: The exposed plate is then developed in a chemical solution, which removes the unexposed areas, leaving the image or text as raised areas on the plate.

- Baking the Plate: The developed plate is baked to harden the image and make it more durable.

2. What are the different types of inks used in offset printing and their applications?

Pigmented Inks

- These inks contain pigments, which are insoluble particles that provide color and opacity.

- They are commonly used for commercial printing, such as brochures, magazines, and newspapers.

Dye-Based Inks

- These inks contain dyes, which are soluble in the solvent or water used in the ink.

- They are known for their vibrant colors and are often used in fine art printing, packaging, and label printing.

Metallic Inks

- These inks contain metallic particles, such as aluminum or bronze, which give a metallic sheen to the printed image.

- They are commonly used in packaging, labels, and decorative printing.

UV Curable Inks

- These inks cure or dry when exposed to ultraviolet light, rather than through evaporation.

- They offer faster drying times and are used in applications where durability and resistance to abrasion are required.

3. Describe the key components of an offset printing press?

- Plate Cylinder: Holds the metal plate with the image or text to be printed.

- Blanket Cylinder: Transfers the image from the plate to the paper.

- Impression Cylinder: Presses the paper against the blanket cylinder to transfer the image.

- Inking System: Supplies ink to the plate cylinder.

- Dampening System: Supplies water to the plate cylinder to prevent the non-image areas from picking up ink.

- Paper Feed System: Feeds the paper into the press.

- Delivery System: Stacks or collects the printed paper.

4. Explain the difference between CMYK and RGB color models?

- CMYK (Cyan, Magenta, Yellow, Key/Black): This color model is used in printing and subtractive color mixing.

- RGB (Red, Green, Blue): This color model is used in digital displays and additive color mixing.

5. What are the common problems that can occur during offset printing and how can they be resolved?

- Color Misregistration: Occurs when the colors are not aligned properly on the printed sheet.

- Improper Ink Density: Can result in faded or too dark printing.

- Paper Curl: Occurs when the printed paper curls or warps due to uneven moisture distribution.

- Smearing: Refers to smudging or blurring of the printed image.

- Ghosting: A faint second image appearing on the printed sheet, usually caused by excessive ink or improper drying.

6. Describe the different types of paper used in offset printing and their characteristics?

- Uncoated Paper: Has a rougher surface and absorbs ink more easily, making it suitable for printing text-heavy documents.

- Coated Paper: Has a smooth surface that provides a glossy or matte finish, enhancing image quality.

- Recycled Paper: Made from recycled materials and is an environmentally friendly option.

- Specialty Papers: Include papers with different colors, textures, or finishes, used for specific applications.

7. What is the purpose of a trap in offset printing?

- A trap is a small overlap between two colors when printing to prevent gaps or white lines from appearing due to misregistration.

8. Explain the importance of prepress in offset printing?

- Prepress involves preparing the files and materials for printing.

- Ensures that the final printed product meets the required specifications and quality standards.

9. What are the safety precautions to be observed when operating an offset printing press?

- Wear appropriate safety gear.

- Keep hands away from moving parts.

- Follow proper operating procedures.

10. Describe your experience in maintaining and troubleshooting offset printing equipment?

- Regularly inspected and cleaned the press.

- Diagnosed and resolved mechanical and electrical issues.

- Calibrated and adjusted the press for optimal performance.

- Ensured that the equipment met safety and quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Assistant Offset Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Assistant Offset Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Assistant Offset Press Operator plays a crucial role in a printing production environment. Their primary task is to assist the Offset Press Operator in the setup, operation, and maintenance of offset presses, ensuring efficient and high-quality printing processes. Key responsibilities include:

1. Press Setup and Operation

- Assisting in the preparation and installation of printing plates on the press.

- Loading and feeding paper rolls or sheets into the press.

- Adjusting press settings to achieve optimal print quality, including ink density, registration, and color balance.

- Monitoring press performance and making adjustments as needed to maintain consistent production.

2. Maintenance and Troubleshooting

- Performing routine maintenance tasks such as cleaning, lubrication, and minor repairs.

- Identifying and troubleshooting press malfunctions promptly to minimize downtime.

- Assisting in major repairs and overhauls as required.

3. Quality Control

- Inspecting printed materials for defects and ensuring compliance with quality standards.

- Maintaining records of press settings and production data for quality assurance purposes.

- Communicating any quality concerns or issues to the Offset Press Operator promptly.

4. Safety and Compliance

- Adhering to safety protocols and operating the press in a safe and responsible manner.

- Ensuring compliance with environmental regulations related to printing operations.

- Wearing appropriate personal protective equipment (PPE) as required.

Interview Tips

Preparing thoroughly for an Assistant Offset Press Operator interview is essential to demonstrate your skills, experience, and enthusiasm for the role. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

- Visit the company’s website and social media pages to learn about their history, values, and current projects.

- Review the job description carefully and identify the specific skills and qualifications required for the position.

2. Practice Your Answers

- Prepare thoughtful and concise answers to common interview questions, such as: “Tell me about yourself,” “Why are you interested in this role,” and “What is your experience with offset printing?”

- Practice your answers aloud and ask a friend or family member for feedback on your presentation and delivery.

3. Showcase Your Skills and Experience

- Highlight your technical skills related to offset printing, such as press setup, color matching, and troubleshooting.

- Quantify your experience by providing specific examples of your contributions to previous printing projects.

- Emphasize your ability to work in a fast-paced and demanding environment.

4. Ask Informed Questions

- Demonstrate your interest in the company and position by asking insightful questions about the printing process, the company’s production schedule, and opportunities for professional development.

- Avoid asking questions that are easily answered by the job description or company website.

5. Dress Professionally and Be Punctual

- Dress in business attire and arrive on time for the interview to show respect for the interviewer and the company.

- Bring a portfolio or samples of your work if relevant to the position.

Next Step:

Now that you’re armed with the knowledge of Assistant Offset Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Assistant Offset Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini