Feeling lost in a sea of interview questions? Landed that dream interview for Auger Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Auger Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

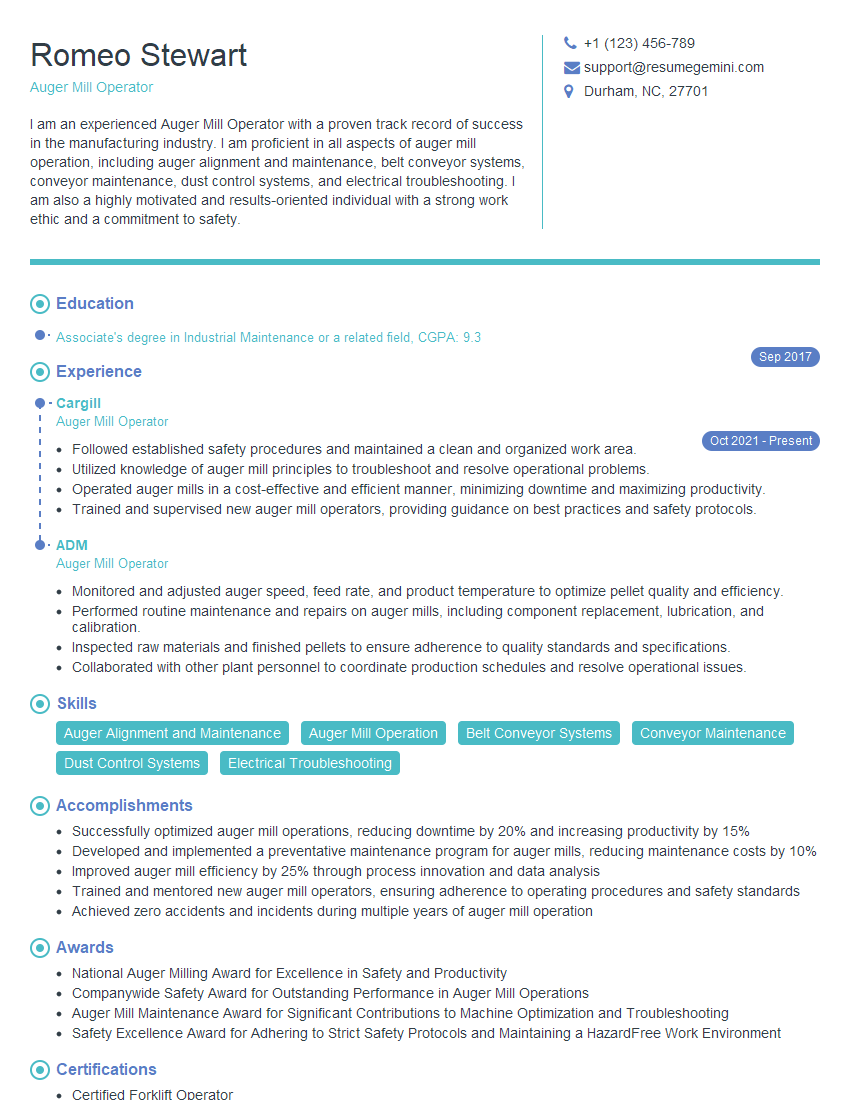

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auger Mill Operator

1. What are the key responsibilities of an Auger Mill Operator?

- Operate and monitor auger mill equipment to grind and blend raw materials.

- Control the flow of materials through the mill and adjust settings to ensure proper mixing and grinding.

- Monitor and maintain equipment, including lubrication, cleaning, and repairs.

- Work with other operators to ensure smooth and efficient production.

- Follow safety protocols and regulations.

2. What are the different types of auger mills and their applications?

Types of Auger Mills

- Horizontal Auger Mills: Used for continuous grinding and mixing of materials that flow easily.

- Vertical Auger Mills: Used for grinding and mixing materials that are difficult to flow or require a high degree of mixing.

Applications

- Food Processing: Grinding grains, spices, and other food ingredients.

- Pharmaceutical Industry: Mixing and grinding pharmaceutical products.

- Chemical Industry: Grinding and mixing chemicals for various applications.

- Waste Management: Grinding and mixing waste materials for disposal or recycling.

3. How do you determine the proper settings for an auger mill based on the materials being processed?

- Consider the material’s hardness, size, and moisture content.

- Adjust the auger speed, screen size, and feed rate to achieve the desired grind size and consistency.

- Monitor the output and make adjustments as needed to optimize performance.

4. What are the common troubleshooting techniques for auger mill malfunctions?

- Check for blockages or clogs in the auger or screen.

- Inspect the bearings and lubricate them if necessary.

- Ensure the motor is receiving sufficient power and is operating properly.

- Check the settings and adjust them to match the material being processed.

- Consult the manufacturer’s instructions or contact the supplier for assistance.

5. How do you maintain and clean an auger mill to ensure optimal performance?

- Regularly clean the auger and screen to remove any buildup or debris.

- Lubricate all moving parts according to the manufacturer’s specifications.

- Inspect the equipment for any signs of wear or damage and make necessary repairs promptly.

- Follow the manufacturer’s recommended maintenance schedule.

6. What safety precautions should be taken when operating an auger mill?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Keep the work area clean and free from hazards.

- Ensure the equipment is properly grounded and shielded.

- Never attempt to clear blockages while the auger is running.

- Follow all safety protocols and procedures.

7. What is the role of a SCADA system in monitoring and controlling an auger mill?

- Provides real-time monitoring of mill parameters, such as speed, temperature, and power consumption.

- Allows for remote control and adjustment of mill settings.

- Records and stores data for analysis and optimization.

- Generates alarms and notifications for any deviations or potential issues.

8. How do you handle variations in material feed rate and ensure consistent output?

- Monitor the feed rate and adjust the auger speed or screen size accordingly.

- Utilize a feeder system to maintain a consistent flow of material into the mill.

- Make gradual adjustments to avoid overfeeding or underfeeding the mill.

9. What experience do you have with different types of materials and how have you adapted your operation to achieve desired results?

- Share experiences with handling various materials, such as grains, plastics, chemicals, or waste.

- Explain how you adjusted mill settings, feed rates, and techniques to achieve optimal results.

- Highlight your ability to troubleshoot and adapt to different material characteristics.

10. What are your career goals and how do you see this role aligning with them?

- Express interest in growing within the field of auger mill operation or related industries.

- Highlight your desire to contribute to process optimization and efficiency.

- Explain how the role aligns with your long-term career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auger Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auger Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Auger Mill Operators are responsible for operating and maintaining auger mills, which are used to grind and mix various materials such as grain, feed, and minerals.

1. Operation of Auger Mills

Operate auger mills according to established procedures and safety regulations.

- Monitor mill operation and make adjustments as needed to ensure efficient and safe operation.

- Control the flow of material through the mill, ensuring a consistent and uniform product.

2. Maintenance of Auger Mills

Perform routine maintenance and repairs on auger mills to ensure optimal performance and longevity.

- Inspect and clean mills regularly, identifying and addressing any potential issues.

- Replace worn or damaged parts, such as bearings, seals, and screens.

- Lubricate and adjust moving parts to minimize friction and wear.

3. Quality Control

Monitor the quality of the milled product, ensuring it meets specifications and customer requirements.

- Collect samples and conduct tests to assess product consistency, particle size, and other quality parameters.

- Make adjustments to the milling process as needed to maintain desired product quality.

4. Health and Safety

Follow established health and safety protocols to ensure a safe and healthy work environment.

- Wear appropriate personal protective equipment (PPE) and follow safe work practices.

- Identify and mitigate potential hazards, such as dust, noise, and moving machinery.

Interview Tips

Preparing for an interview for an Auger Mill Operator position requires careful research and practice.

1. Research the Company

Learn about the company’s history, mission, values, and products or services.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the company’s activities.

2. Practice Common Interview Questions

Familiarize yourself with common interview questions and prepare your responses.

- Tell me about yourself and why you’re interested in this position?

- Describe your experience with operating and maintaining auger mills?

- How do you ensure the quality of the milled product?

- How do you handle health and safety concerns in the workplace?

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job requirements.

- Quantify your accomplishments using specific metrics and data.

- Provide examples of how you have successfully solved problems and improved efficiency in previous roles.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest in the position and the company.

- What are the company’s goals for this role?

- What opportunities are there for professional development and advancement?

- What are the biggest challenges facing the company in the industry?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Auger Mill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Auger Mill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.