Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Auto Bumper Straightener interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Auto Bumper Straightener so you can tailor your answers to impress potential employers.

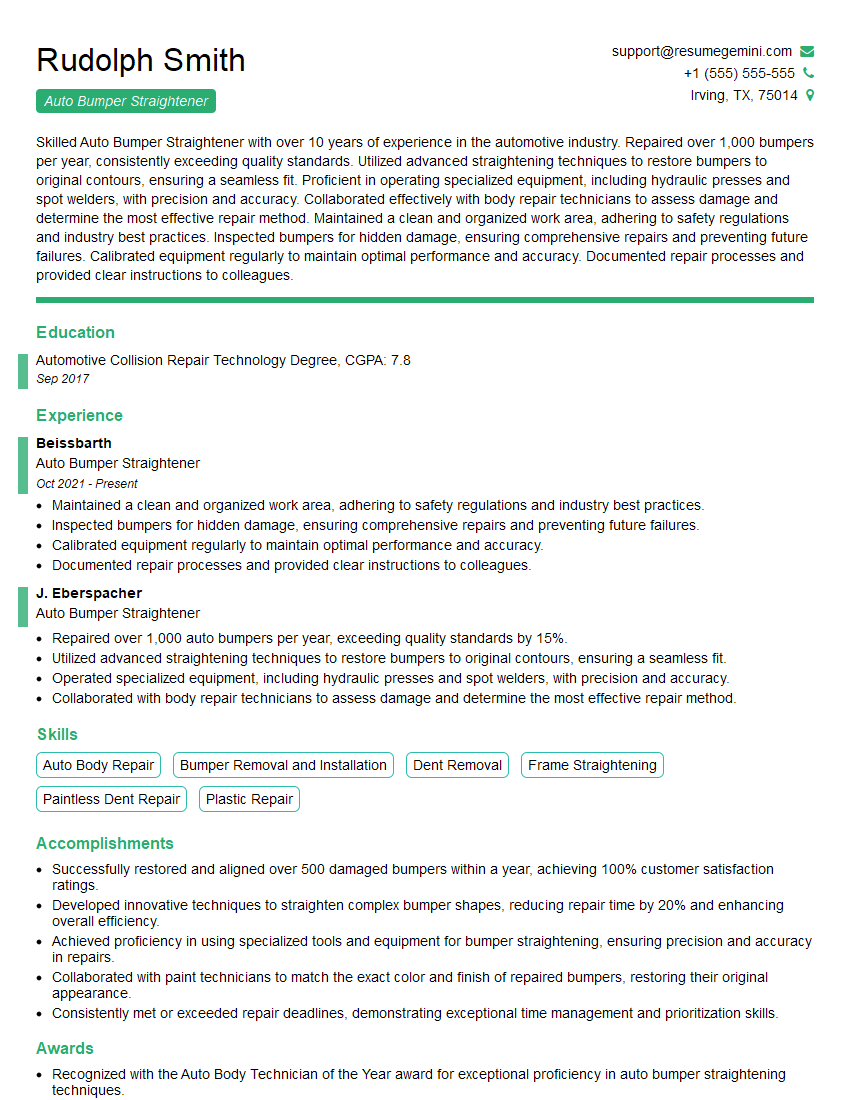

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto Bumper Straightener

1. What are the different types of auto bumper materials and their characteristics?

Auto bumpers are typically made from one of three materials: plastic, metal, or fiberglass.

- Plastic bumpers are the most common type, and they are made from a variety of polymers, including polyethylene, polypropylene, and polyurethane. Plastic bumpers are lightweight, durable, and corrosion-resistant. They are also relatively inexpensive to manufacture.

- Metal bumpers are made from steel or aluminum. They are stronger than plastic bumpers, but they are also heavier and more expensive. Metal bumpers are often used on trucks and other heavy-duty vehicles.

- Fiberglass bumpers are made from a composite material that consists of fiberglass fibers embedded in a resin. Fiberglass bumpers are lightweight and strong, and they can be molded into a variety of shapes. They are also more expensive than plastic or metal bumpers.

2. What are the steps involved in repairing a plastic bumper?

Assessing the damage

- Inspect the bumper for cracks, scratches, and dents.

- Determine the extent of the damage and whether it can be repaired.

Preparing the bumper for repair

- Clean the bumper with a mild detergent and water.

- Sand the damaged area with a fine-grit sandpaper to remove any rough edges.

- Mask off the surrounding area to protect it from overspray.

Repairing the bumper

- Apply a thin layer of plastic filler to the damaged area.

- Sand the filler smooth once it has dried.

- Prime the repaired area and allow it to dry.

- Paint the repaired area to match the rest of the bumper.

Finishing the repair

- Remove the masking tape.

- Buff and polish the repaired area to restore its original shine.

3. What are the different types of welding used to repair metal bumpers?

- MIG welding is a type of arc welding that uses a continuously fed wire electrode. MIG welding is fast and efficient, and it can be used to weld a variety of metals, including steel, aluminum, and stainless steel.

- TIG welding is a type of arc welding that uses a non-consumable tungsten electrode. TIG welding is slower than MIG welding, but it produces a higher quality weld. TIG welding is often used to weld thin metals and exotic metals.

- Oxyacetylene welding is a type of gas welding that uses a mixture of oxygen and acetylene. Oxyacetylene welding is versatile and can be used to weld a variety of metals, including steel, aluminum, and cast iron.

4. How do you repair a fiberglass bumper?

- Clean the bumper with a mild detergent and water.

- Sand the damaged area with a fine-grit sandpaper to remove any rough edges.

- Apply a layer of fiberglass resin to the damaged area.

- Reinforce the repair with fiberglass cloth or mat.

- Allow the repair to dry and harden.

- Sand the repaired area smooth.

- Prime and paint the repaired area to match the rest of the bumper.

5. What are the different types of auto body fillers?

- Plastic fillers are made from a variety of polymers, including polyester, epoxy, and polyurethane. Plastic fillers are lightweight and easy to sand, but they can be brittle.

- Metal fillers are made from a mixture of metal particles and resin. Metal fillers are stronger than plastic fillers, but they are also heavier and more difficult to sand.

- Universal fillers are a combination of plastic and metal fillers. Universal fillers are versatile and can be used for a variety of repairs.

6. How do you choose the right auto body filler for a particular repair?

- The type of damage – Plastic fillers are best for small repairs, such as scratches and dents. Metal fillers are best for larger repairs, such as holes and cracks. Universal fillers can be used for a variety of repairs.

- The material of the bumper – Plastic fillers are best for plastic bumpers. Metal fillers are best for metal bumpers. Universal fillers can be used on either plastic or metal bumpers.

- The desired finish – Plastic fillers produce a smooth finish. Metal fillers produce a more textured finish. Universal fillers can produce a variety of finishes, depending on the type of filler used.

7. What are the different types of auto body paint?

- Lacquer is a type of paint that dries quickly and produces a glossy finish. Lacquer is easy to apply, but it is not as durable as other types of paint.

- Enamel is a type of paint that dries slowly and produces a hard, durable finish. Enamel is more difficult to apply than lacquer, but it is more durable.

- Urethane is a type of paint that combines the best qualities of lacquer and enamel. Urethane is durable, easy to apply, and produces a high-gloss finish.

8. How do you choose the right auto body paint for a particular repair?

- The type of repair – Lacquer is best for small repairs, such as scratches and dents. Enamel is best for larger repairs, such as holes and cracks. Urethane can be used for a variety of repairs.

- The material of the bumper – Lacquer is best for plastic bumpers. Enamel is best for metal bumpers. Urethane can be used on either plastic or metal bumpers.

- The desired finish – Lacquer produces a glossy finish. Enamel produces a hard, durable finish. Urethane produces a high-gloss finish.

9. What are the different types of auto body tools?

- Hand tools – Hand tools include hammers, wrenches, screwdrivers, and pliers. Hand tools are used for a variety of tasks, such as removing and installing parts, and shaping and forming metal.

- Power tools – Power tools include drills, sanders, and grinders. Power tools are used for a variety of tasks, such as drilling holes, sanding surfaces, and grinding metal.

- Specialty tools – Specialty tools are designed for specific tasks, such as dent removal and paint repair. Specialty tools are often more expensive than hand tools and power tools, but they can make certain tasks much easier.

10. How do you maintain auto body tools?

- Clean tools after each use – Cleaning tools after each use will help to prevent rust and corrosion. Use a mild detergent and water to clean tools, and then dry them thoroughly with a clean cloth.

- Lubricate moving parts – Lubricating moving parts will help to keep tools working smoothly. Use a light oil or grease to lubricate moving parts, such as hinges and bearings.

- Store tools in a dry place – Storing tools in a dry place will help to prevent rust and corrosion. If possible, store tools in a climate-controlled environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto Bumper Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto Bumper Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Auto Bumper Straighteners are responsible for repairing and replacing damaged bumpers on vehicles. They work in automotive repair shops and dealerships, and their duties include:

1. Inspecting damaged bumpers

Auto Bumper Straighteners must be able to identify the extent of damage to a bumper and determine the best course of action for repair.

- Assessing the severity of the damage

- Determining if the bumper can be repaired or needs to be replaced

- Determining the type of repair needed (e.g., welding, painting, etc.)

2. Removing and repairing bumpers

Auto Bumper Straighteners must be able to safely remove and repair bumpers.

- Removing the bumper from the vehicle

- Repairing the bumper using a variety of tools and techniques (e.g., welding, painting, etc.)

- Reattaching the bumper to the vehicle

3. Painting bumpers

Auto Bumper Straighteners must be able to paint bumpers to match the color of the vehicle.

- Preparing the bumper for painting

- Applying primer to the bumper

- Painting the bumper

- Applying clear coat to the bumper

4. Polishing and detailing bumpers

Auto Bumper Straighteners must be able to polish and detail bumpers to restore their shine and appearance.

- Polishing the bumper

- Applying wax or sealant to the bumper

- Detailing the bumper

Interview Tips

To prepare for an Auto Bumper Straightener interview, candidates should:

1. Research the company and the position

Candidates should research the company they are interviewing with and the specific position they are applying for. This will help them to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Learn about the company’s products or services

- Research the company’s competitors

2. Practice answering common interview questions

Candidates should practice answering common interview questions so that they can deliver their answers confidently and clearly. Some common interview questions that candidates may be asked include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with bumper repair?

- What is your hourly rate?

3. Dress professionally and arrive on time

Candidates should dress professionally for their interview and arrive on time. This will show the interviewer that they are serious about the position and that they respect the interviewer’s time.

- Wear a suit or business casual attire

- Be well-groomed and clean-shaven

- Arrive on time for your interview

4. Be prepared to talk about your experience

Candidates should be prepared to talk about their experience repairing bumpers. This includes discussing the types of repairs they have done, the tools and techniques they have used, and the results they have achieved.

- Describe the most challenging bumper repair you have ever done

- Explain the steps you took to repair the bumper

- Discuss the results of the repair

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Auto Bumper Straightener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!