Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Auto Clutch Rebuilder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

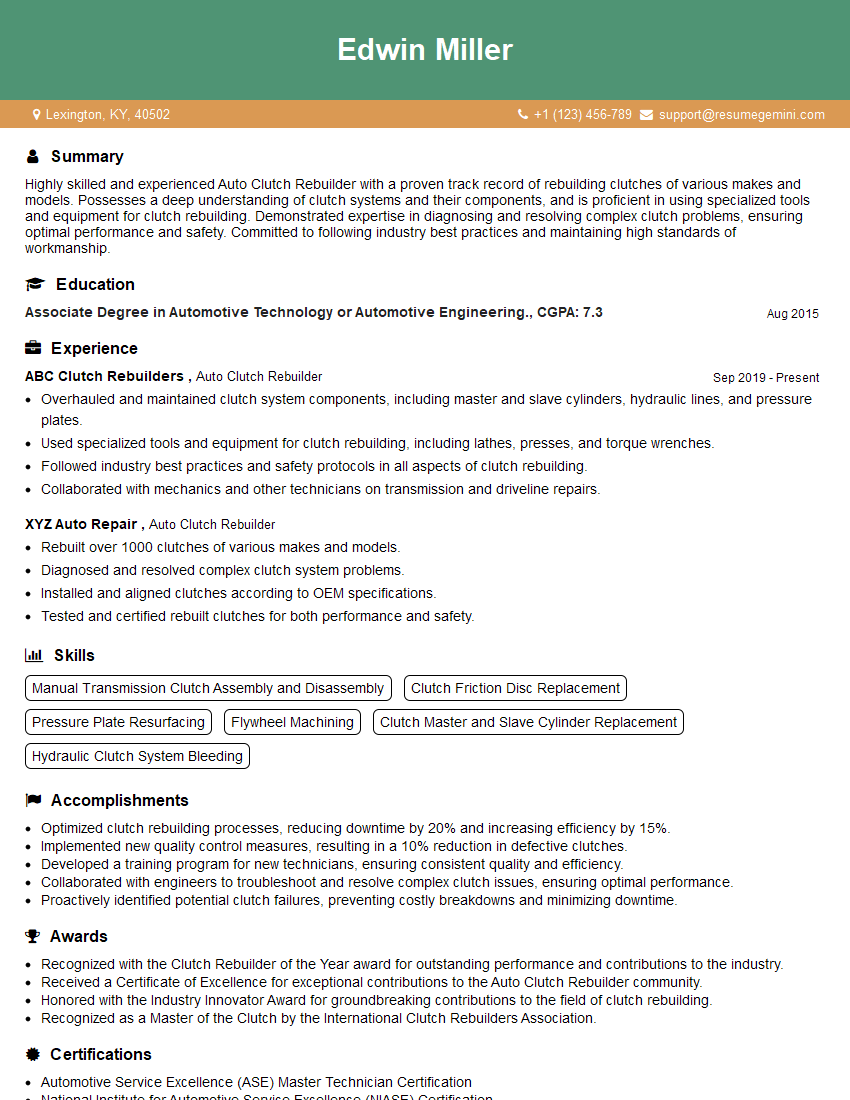

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto Clutch Rebuilder

1. Explain the process of rebuilding an auto clutch?

A clutch rebuild involves disassembling, inspecting, and replacing worn or damaged components. The process typically includes the following steps:

- Inspecting the clutch assembly for signs of wear or damage

- Disassembling the clutch assembly, including removing the pressure plate, clutch disc, and flywheel

- Inspecting all components for wear or damage, and replacing any that are worn or damaged

- Resurfacing the flywheel to ensure a smooth surface for the clutch disc to engage

- Reassembling the clutch assembly, ensuring that all components are properly aligned and torqued

- Testing the clutch assembly to ensure proper operation

2. What are the common types of clutch problems and their causes?

Types of Clutch Problems

- Slipping clutch

- Grabbing clutch

- Juddering clutch

- Heavy clutch pedal

Causes of Clutch Problems

- Worn clutch disc

- Damaged pressure plate

- Faulty release bearing

- Hydraulic or cable issues

3. What are the different types of clutch discs and their applications?

- Organic clutch discs: Made from organic materials such as cotton or paper, organic clutch discs are known for their smooth engagement and durability.

- Ceramic clutch discs: Made from ceramic materials, ceramic clutch discs are designed for high-performance applications and can withstand extreme temperatures and wear.

- Sintered metal clutch discs: Made from a combination of metal powders, sintered metal clutch discs are known for their durability and heat resistance.

4. How do you diagnose a slipping clutch?

- Check for signs of excessive heat or burning on the clutch disc

- Look for any signs of wear or damage on the pressure plate or flywheel

- Check the hydraulic or cable system for leaks or damage

- Perform a road test and observe the clutch engagement and disengagement

5. What are the torque specifications for a clutch assembly?

The torque specifications for a clutch assembly vary depending on the make and model of the vehicle. It is important to refer to the manufacturer’s specifications for the correct torque values.

6. How do you adjust a clutch pedal?

- Locate the clutch pedal adjustment mechanism, which is usually located near the top of the clutch pedal

- Use a wrench or pliers to adjust the length of the pushrod or cable

- Adjust the pedal until there is approximately 1 inch of free play at the top of the pedal travel

7. What are the safety precautions to be taken when working on a clutch assembly?

- Always wear safety glasses and gloves

- Ensure that the vehicle is properly supported and the parking brake is engaged

- Disconnect the battery negative terminal before working on the clutch assembly

- Be aware of hot surfaces and sharp edges

- Never attempt to work on a clutch assembly while the engine is running

8. What are the different types of clutch release mechanisms?

- Mechanical release mechanism: Uses a lever or fork to disengage the clutch

- Hydraulic release mechanism: Uses a hydraulic cylinder to disengage the clutch

- Cable release mechanism: Uses a cable to disengage the clutch

9. How do you test a clutch release bearing?

- Listen for any unusual noises coming from the clutch area

- Check for any signs of wear or damage on the release bearing

- Perform a road test and observe the clutch engagement and disengagement

10. What are the signs of a worn clutch?

- Slipping clutch

- Grabbing clutch

- Juddering clutch

- Heavy clutch pedal

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto Clutch Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto Clutch Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Auto Clutch Rebuilder is responsible for rebuilding and repairing clutches in vehicles. They work with a variety of clutches, including manual transmissions, automatic transmissions, and dual-clutch transmissions.

1. Disassemble and Inspect Clutches

Auto Clutch Rebuilders disassemble clutches to inspect them for wear and tear. They look for signs of damage, such as worn or broken friction plates, damaged pressure plates, or warped flywheels.

- Identify and assess the condition of clutch components, including friction plates, pressure plates, release bearings, and flywheels.

- Determine the root cause of clutch failure and recommend appropriate repairs.

2. Repair and Rebuild Clutches

Auto Clutch Rebuilders repair and rebuild clutches by replacing worn or damaged components. They may also resurface flywheels or pressure plates to create a smooth surface for the clutch to engage with.

- Replace worn or damaged clutch components, such as friction plates, pressure plates, and release bearings.

- Resurface flywheels and pressure plates to restore a smooth friction surface.

- Reassemble and adjust clutches to ensure proper operation.

3. Test and Adjust Clutches

Auto Clutch Rebuilders test and adjust clutches to ensure that they are functioning properly. They may use a variety of tools, such as a clutch alignment tool or a torque wrench, to make sure that the clutch is properly adjusted.

- Test clutches to verify proper engagement and disengagement.

- Adjust clutches to meet manufacturer specifications.

- Document repairs and adjustments for future reference.

4. Maintain a Clean and Organized Work Area

Auto Clutch Rebuilders must maintain a clean and organized work area to ensure the safety and efficiency of their work. They may also be responsible for cleaning and maintaining tools and equipment.

- Keep work area clean and free of debris.

- Maintain tools and equipment in good working condition.

- Follow safety protocols to prevent accidents and injuries.

Interview Tips

Preparing for an interview can be a daunting task, but with the right strategies, you can increase your chances of success. Here are some interview tips for auto clutch rebuilders:

1. Research the Company and Position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get an idea of the work environment and culture.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this job?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- Tailor your answers to the specific job you are applying for.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as an auto clutch rebuilder. Be prepared to talk about your training, certifications, and any relevant work experience you have.

- Highlight your technical skills, such as your ability to diagnose and repair clutch problems.

- Emphasize your customer service skills, such as your ability to communicate effectively and build relationships.

- Discuss your safety record and your commitment to quality workmanship.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the job and that you respect their time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive at the interview location a few minutes early to give yourself time to relax and prepare.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Auto Clutch Rebuilder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.