Are you gearing up for a career in Auto Machinist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Auto Machinist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

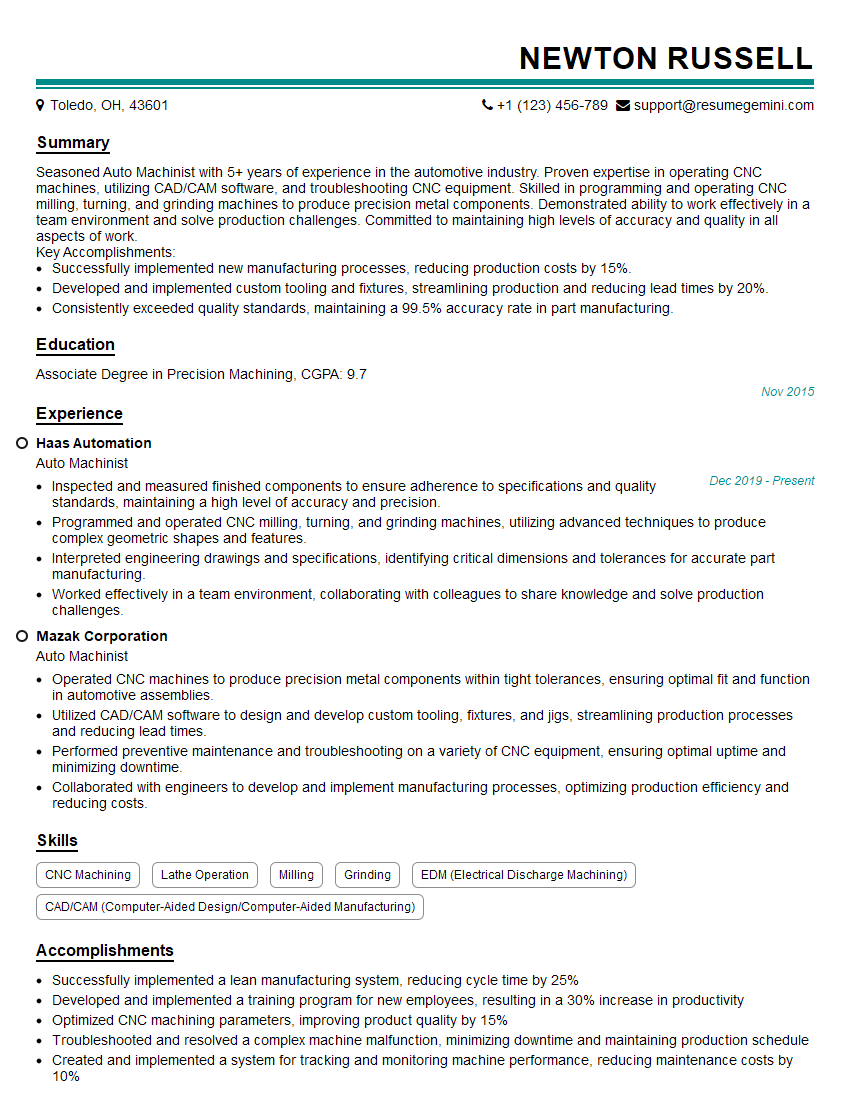

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto Machinist

1. Explain the process of precision machining?

Precision machining is a manufacturing process that removes material from a workpiece in a controlled manner to achieve precise dimensions and tolerances. It involves the use of cutting tools, such as CNC machines, to remove material in increments, resulting in highly accurate and repeatable parts. Key steps in precision machining include:

- Creating a design or model of the desired part using CAD software

- Selecting the appropriate cutting tools and materials for the job

- Programming the CNC machine to execute the cutting operations

- Monitoring the machining process to ensure accuracy and quality

- Inspecting and validating the finished part to ensure it meets specifications

2. Describe the different types of CNC machines and their capabilities?

There are several types of CNC machines, each with its own capabilities and applications. Some common types include:

Milling machines

- Used for creating complex shapes and contours on workpieces

- Can perform operations such as drilling, boring, milling, and contouring

Turning machines

- Used for creating cylindrical parts

- Can perform operations such as turning, facing, grooving, and threading

Grinding machines

- Used for finishing and precision grinding of workpieces

- Can remove small amounts of material to achieve high surface finishes and tight tolerances

Electrical discharge machining (EDM) machines

- Used for machining complex shapes and materials that are difficult to cut with conventional tools

- Employs electrical sparks to erode material from the workpiece

3. What types of materials can be machined using precision machining?

Precision machining can be used to machine a wide variety of materials, including:

- Metals (e.g., steel, aluminum, titanium)

- Plastics

- Ceramics

- Composites

4. What are the key factors to consider when selecting cutting tools for precision machining?

When selecting cutting tools for precision machining, several key factors need to be considered:

- The material being machined

- The desired surface finish

- The accuracy and tolerances required

- The type of machine being used

- The cutting tool geometry

- The cutting tool material

5. How do you ensure quality and accuracy in precision machining?

Ensuring quality and accuracy in precision machining involves implementing several measures:

- Using high-quality materials and cutting tools

- Maintaining proper machine setup and calibration

- Following established machining procedures

- Conducting regular inspections and measurements

- Implementing quality control systems

6. What are the common challenges faced in precision machining?

Common challenges faced in precision machining include:

- Achieving high surface finishes

- Maintaining tight tolerances

- Minimizing tool wear and breakage

- Controlling vibration and chatter

- Ensuring dimensional stability of workpieces

7. How do you stay up-to-date with the latest advancements in precision machining?

Staying up-to-date with the latest advancements in precision machining requires:

- Attending industry conferences and exhibitions

- Reading trade publications and technical journals

- Participating in online forums and discussions

- Consulting with experts and manufacturers

- Investing in training and development

8. What are some of the emerging trends in precision machining?

Some emerging trends in precision machining include:

- Increased use of automation and robotics

- Development of new cutting tool materials and geometries

- Integration of additive manufacturing techniques

- Focus on sustainable and environmentally friendly machining

- Advancements in measurement and inspection technologies

9. How do you handle complex or unusual machining projects?

Handling complex or unusual machining projects requires:

- Thorough planning and preparation

- Collaboration with designers and engineers

- Use of specialized tooling and techniques

- Regular monitoring and adjustment

- Flexibility and problem-solving skills

- Attention to detail and quality control

10. What are your career goals and aspirations in the field of precision machining?

My career goals and aspirations in precision machining are to:

- Develop and refine my skills as a highly skilled machinist

- Contribute to the production of high-quality and innovative products

- Advance my knowledge and expertise in the field

- Take on leadership roles within the machining industry

- Make a positive impact on the manufacturing sector

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Auto Machinist is a highly skilled professional responsible for operating and maintaining sophisticated machinery to manufacture and repair automotive components with utmost precision. Their key responsibilities include:1. Manufacturing and Repairing Automotive Components

Auto Machinists specialize in producing and repairing intricate automotive components, such as engine blocks, crankshafts, and transmission parts.

- Operate CNC machines, lathes, and grinders to shape and finish metal components according to specifications.

- Inspect and measure components using precision instruments to ensure they meet quality standards.

- Repair worn or damaged components by welding, grinding, and replacing parts.

2. Machine Setup and Maintenance

Auto Machinists play a crucial role in ensuring the proper functioning of machinery.

- Set up and calibrate machines according to blueprints and work orders.

- Regularly inspect and maintain machines to prevent breakdowns and ensure optimal performance.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

3. Quality Control and Assurance

Maintaining the highest quality standards is paramount for Auto Machinists.

- Inspect finished components to ensure they adhere to specifications and industry standards.

- Implement quality control measures throughout the manufacturing process to minimize defects.

- Document all inspection and testing results to maintain a comprehensive record of quality.

4. Safety and Compliance

Auto Machinists prioritize safety and compliance in their workplace.

- Follow established safety protocols and wear appropriate personal protective equipment.

- Ensure that machinery is properly guarded and maintained to prevent accidents.

- Adhere to industry regulations and environmental standards related to manufacturing processes.

Interview Tips

Preparing thoroughly for an Auto Machinist interview is essential to showcase your skills and land the job. Consider the following tips:1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company’s history, products, and industry reputation. Study the job description thoroughly to understand the specific requirements and expectations.

2. Highlight Your Technical Skills

Auto Machinists are highly skilled professionals. Focus on showcasing your expertise in operating and maintaining CNC machines, lathes, and grinders. Provide specific examples of projects where you successfully applied these skills.

3. Emphasize Quality and Precision

Quality and precision are crucial in auto machining. Share instances where you implemented quality control measures or resolved production issues to ensure high-quality results.

4. Communicate Your Safety Consciousness

Safety is paramount in this field. Emphasize your commitment to following safety protocols, wearing appropriate protective gear, and maintaining a safe work environment.

Example Outline

When answering interview questions, consider using the STAR method to provide clear and concise responses:

- Situation: Briefly describe the situation or task you faced.

- Task: Explain your role and responsibilities in the situation.

- Action: Describe the specific actions you took to address the situation.

- Result: Highlight the positive outcome or impact of your actions.

Next Step:

Now that you’re armed with the knowledge of Auto Machinist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Auto Machinist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini