Are you gearing up for an interview for a Auto Roller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Auto Roller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

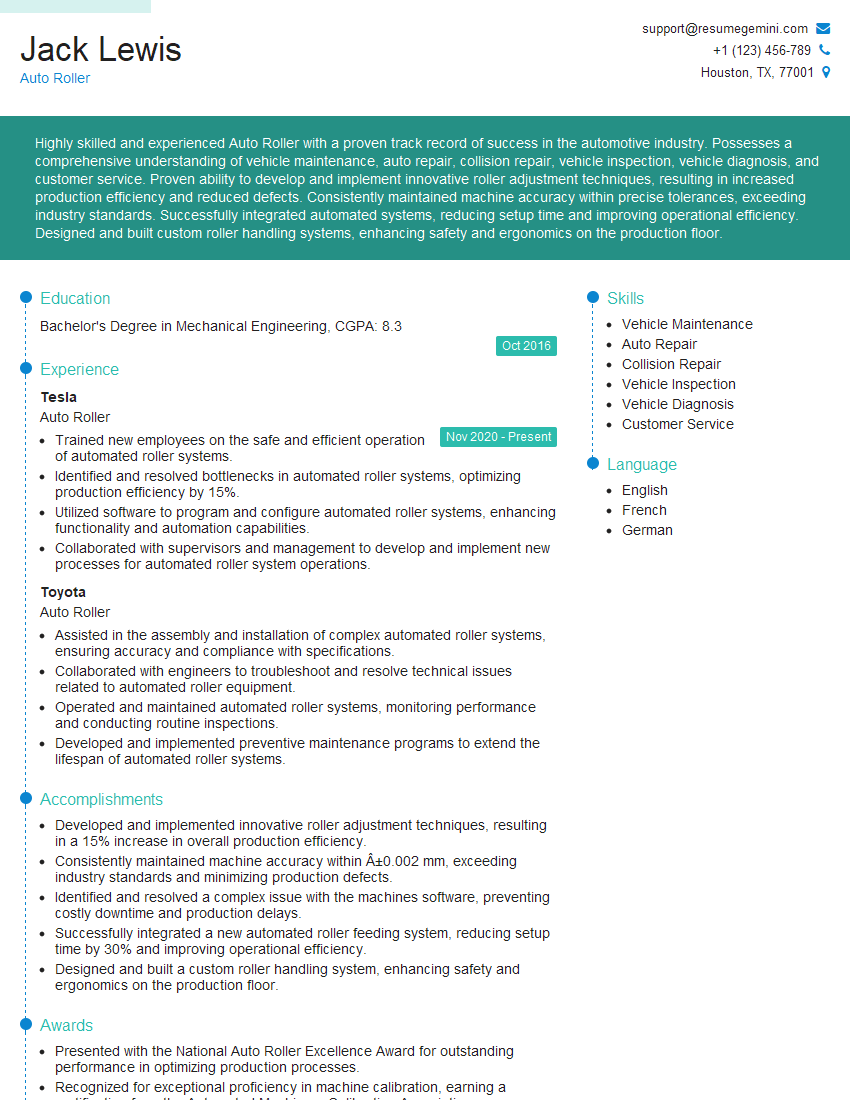

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto Roller

1. How do you measure the efficiency of an auto roller?

To measure the efficiency of an auto roller, I would consider the following factors:

- Coverage rate: The area that the auto roller can cover in a given amount of time.

- Compaction rate: The density that the auto roller can achieve in a given number of passes.

- Fuel consumption: The amount of fuel that the auto roller consumes per hour of operation.

- Maintenance costs: The cost of maintaining and repairing the auto roller over its lifetime.

2. What are the key features to look for when selecting an auto roller?

Durability

- The frame and components should be made of high-quality materials that can withstand the rigors of construction work.

- The auto roller should have a good warranty.

Performance

- The auto roller should have a powerful engine that can provide enough torque to compact the soil effectively.

- The auto roller should have a wide drum that can cover a large area in a short amount of time.

Ease of use

- The auto roller should have intuitive controls that are easy to learn and operate.

- The auto roller should be able to maneuver easily in tight spaces.

3. What are the different types of auto rollers available?

There are several different types of auto rollers available, each with its own advantages and disadvantages:

- Static auto rollers: These auto rollers have a heavy drum that provides a high compaction force. They are typically used for compacting soil and asphalt.

- Vibratory auto rollers: These auto rollers have a drum that vibrates as it rolls, which helps to compact the soil more effectively. They are typically used for compacting soil and gravel.

- Pneumatic auto rollers: These auto rollers have a drum that is filled with air, which provides a more uniform compaction force. They are typically used for compacting sand and other loose materials.

4. What are the safety precautions that should be taken when operating an auto roller?

When operating an auto roller, it is important to take the following safety precautions:

- Always wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and watch for other workers and equipment.

- Operate the auto roller at a safe speed.

- Never leave the auto roller unattended while it is running.

- Follow all manufacturer’s instructions for operating and maintaining the auto roller.

5. What are the maintenance requirements for an auto roller?

To keep an auto roller in good working condition, it is important to perform regular maintenance, which may include the following tasks:

- Checking the oil and coolant levels.

- Greasing the bearings.

- Inspecting the tires for wear and tear.

- Cleaning the air filter.

- Having the auto roller serviced by a qualified technician on a regular basis.

6. What are the common problems that can occur with auto rollers?

Some of the common problems that can occur with auto rollers include:

- Engine problems: These can include problems with the starter, alternator, or fuel system.

- Transmission problems: These can include problems with the gears, clutch, or torque converter.

- Hydraulic problems: These can include problems with the hydraulic pump, hoses, or cylinders.

- Electrical problems: These can include problems with the wiring, lights, or sensors.

7. What are the troubleshooting steps for an auto roller that is not starting?

If an auto roller is not starting, the following troubleshooting steps can be taken:

- Check the battery to make sure that it is connected and has a sufficient charge.

- Check the starter to make sure that it is working properly.

- Check the fuel system to make sure that there is fuel in the tank and that the fuel lines are not clogged.

- Check the ignition system to make sure that the spark plugs are firing properly.

8. What are the troubleshooting steps for an auto roller that is not compacting the soil properly?

If an auto roller is not compacting the soil properly, the following troubleshooting steps can be taken:

- Check the drum to make sure that it is clean and free of debris.

- Check the tire pressure to make sure that it is set to the correct level.

- Check the water tank to make sure that it is full and that the water is flowing properly.

- Check the engine to make sure that it is running at the correct speed.

9. What are the latest trends in auto roller technology?

Some of the latest trends in auto roller technology include:

- GPS-enabled auto rollers: These auto rollers use GPS technology to track their location and progress, which helps to ensure that the soil is compacted evenly and to the correct specifications.

- Solar-powered auto rollers: These auto rollers use solar panels to generate electricity, which helps to reduce fuel consumption and emissions.

- Electric auto rollers: These auto rollers are powered by electric motors, which helps to reduce noise and emissions.

10. What are the key factors to consider when purchasing an auto roller?

When purchasing an auto roller, the following key factors should be considered:

- The type of soil that will be compacted.

- The size of the area that will be compacted.

- The budget for the auto roller.

- The features that are desired in the auto roller.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Auto Roller is responsible for operating and maintaining road rollers used in the construction and maintenance of roads, parking lots, and other paved surfaces.

1. Preparing the Work Area

Before operating the roller, the Auto Roller must prepare the work area by clearing away any debris, such as rocks, sticks, or other objects that could damage the roller or the pavement.

- Inspecting the work area for any hazards

- Setting up traffic control devices, such as cones or signs

2. Operating the Roller

Once the work area is prepared, the Auto Roller can begin operating the roller. The Auto Roller must follow the manufacturer’s instructions for operating the roller and must be aware of the surroundings at all times.

- Controlling the speed and direction of the roller

- Adjusting the roller’s settings, such as the vibration frequency and amplitude

- Monitoring the roller’s performance and making adjustments as needed

3. Maintaining the Roller

In addition to operating the roller, the Auto Roller is also responsible for maintaining the roller. This includes cleaning the roller, lubricating the moving parts, and checking the roller for any damage.

- Cleaning the roller after each use

- Lubricating the moving parts regularly

- Checking the roller for any damage and making repairs as needed

4. Other Duties

In addition to the above responsibilities, the Auto Roller may also be responsible for:

- Assisting with the setup and breakdown of the job site

- Loading and unloading the roller from the transport trailer

- Performing other duties as assigned by the supervisor

Interview Tips

Preparing for an interview for an Auto Roller position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare for your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, Glassdoor, and other online resources.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer behavioral questions

- Prepare questions to ask the interviewer

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a construction environment.

4. Be Punctual

Punctuality is important for any job interview, but it is especially important for an Auto Roller position. This is because construction projects are often time-sensitive, and you will need to be able to start work on time.

5. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about the job. Be sure to convey your excitement about the opportunity to work as an Auto Roller and highlight your positive attitude.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Auto Roller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.