Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Auto-Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

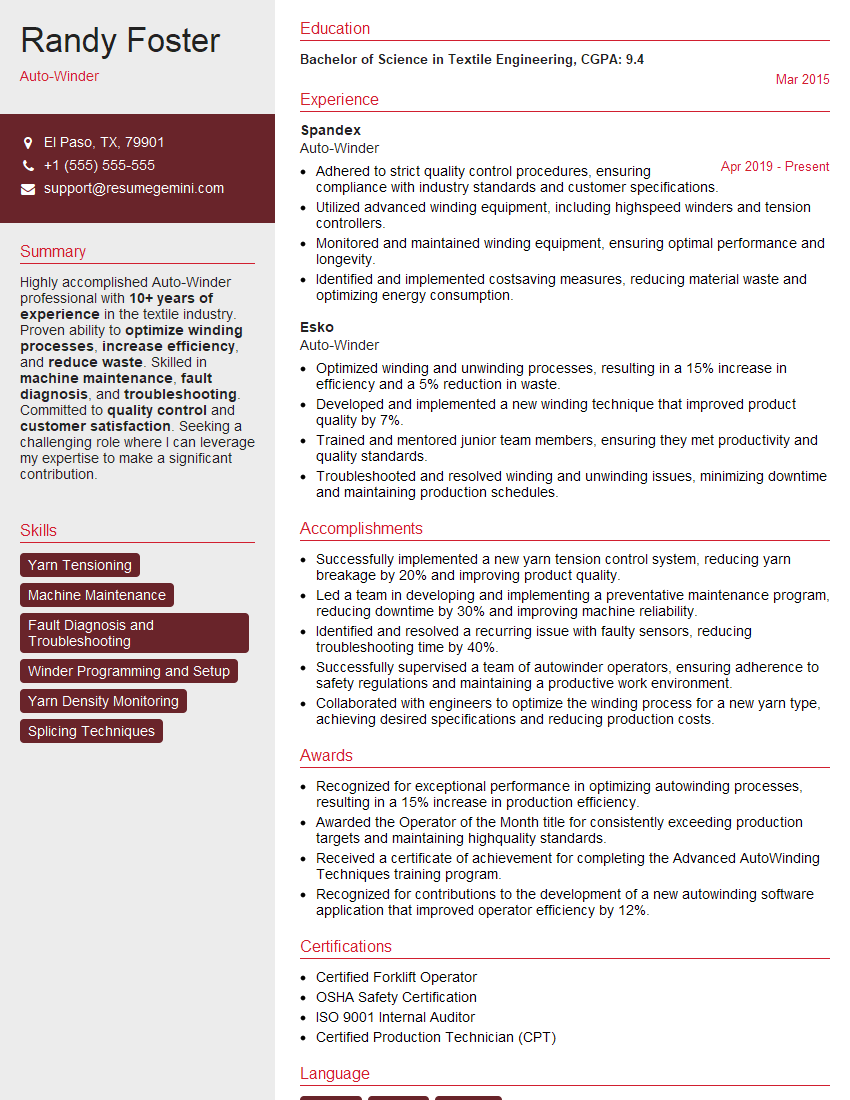

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Auto-Winder

1. Explain the working principle of an Auto-Winder?

An Auto-Winder is a machine used in the textile industry to automatically wind yarn onto bobbins or tubes. It consists of several components that work together to achieve precise and efficient winding:

- Creel: Holds the supply bobbins containing the raw yarn.

- Tensioner: Controls the tension of the yarn as it passes through the machine.

- Traversing Mechanism: Moves the yarn back and forth across the bobbin or tube to create a uniform and evenly distributed winding.

- Winding Head: Rotates the bobbin or tube while the yarn is being wound, ensuring proper winding speed and tension.

- Control System: Monitors and adjusts the machine’s parameters, such as winding speed, tension, and traverse length, to achieve optimal performance.

2. What are the different types of Auto-Winders and their applications?

Types of Auto-Winders:

- Single-Spindle Auto-Winder: Used for winding yarn onto a single bobbin or tube.

- Multi-Spindle Auto-Winder: Can wind yarn onto multiple bobbins or tubes simultaneously, increasing productivity.

- Precision Auto-Winder: Designed for high-precision winding of delicate or fine yarns.

Applications:

- Textile manufacturing: Preparing yarn for weaving, knitting, or other textile processes.

- Electrical wire industry: Winding wire onto coils or spools.

- Plastic film manufacturing: Winding plastic film onto rolls.

3. Describe the key components of an Auto-Winder and their functions.

- Yarn Creel: Holds the supply bobbins containing the raw yarn.

- Yarn Tensioner: Controls the tension of the yarn as it passes through the machine.

- Traversing Mechanism: Moves the yarn back and forth across the bobbin or tube to create a uniform and evenly distributed winding.

- Winding Head: Rotates the bobbin or tube while the yarn is being wound, ensuring proper winding speed and tension.

- Control System: Monitors and adjusts the machine’s parameters, such as winding speed, tension, and traverse length, to achieve optimal performance.

4. How do you ensure the quality of yarn winding on an Auto-Winder?

- Proper Machine Calibration: Ensure that the Auto-Winder is calibrated and maintained to ensure accurate winding parameters.

- Yarn Tension Control: Adjust the yarn tensioner to maintain the appropriate tension throughout the winding process, preventing yarn breakage or uneven winding.

- Traverse Monitoring: Monitor the traverse length and ensure it is consistent to achieve uniform yarn distribution on the bobbin or tube.

- Winding Speed Optimization: Set the winding speed to match the yarn quality and desired winding density.

- Regular Inspection: Regularly inspect the yarn winding to identify any defects or irregularities and make necessary adjustments.

5. Describe the process of setting up and operating an Auto-Winder.

Process Outline:

- Machine Setup: Install the machine, connect power, and ensure all components are properly assembled.

- Yarn Loading: Load the supply bobbins onto the creel and thread the yarn through the tensioner and traversing mechanism.

- Parameter Adjustments: Set the winding speed, tension, traverse length, and other parameters based on the desired winding requirements.

- Start Winding: Initiate the winding process by pressing the start button.

- Monitoring: Monitor the winding process, inspect the yarn quality, and make any necessary adjustments to maintain optimal performance.

6. How do you troubleshoot common problems encountered during Auto-Winder operation?

- Yarn Breakage: Check tension settings, verify the yarn path, and inspect for any obstructions or damage.

- Uneven Winding: Adjust the traverse length, check the traversing mechanism, and ensure proper yarn tension.

- Excessive Noise: Inspect for any loose parts, worn bearings, or misalignment of components.

- Machine Malfunctions: Follow the manufacturer’s troubleshooting guide, check electrical connections, and contact technical support if necessary.

- Poor Yarn Quality: Inspect the yarn for defects, check the winding parameters, and consult with the yarn supplier.

7. How do you maintain an Auto-Winder to ensure optimal performance?

- Regular Cleaning: Remove dust and debris from the machine, paying attention to areas where yarn passes through.

- Lubrication: Follow the manufacturer’s recommendations for lubricating moving parts to reduce wear and tear.

- Component Inspection: Regularly inspect components such as tensioners, traversing mechanisms, and winding heads for any damage or wear.

- Calibration Checks: Conduct regular calibration checks on the machine to ensure accuracy and consistency of winding parameters.

- Software Updates: Install software updates and patches as recommended by the manufacturer to improve machine performance and reliability.

8. What are the safety precautions to consider when operating an Auto-Winder?

- Machine Guarding: Ensure that all machine guards are in place and functioning properly to prevent contact with moving parts.

- Personal Protective Equipment: Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards.

- Electrical Safety: Follow electrical safety protocols, check connections, and avoid operating the machine with exposed wires or damaged cords.

- Yarn Handling: Be cautious when handling yarn to prevent entanglement or injury.

- Training and Safety Instructions: Ensure that all operators are trained and follow the manufacturer’s safety instructions.

9. Discuss the advancements in Auto-Winder technology and their impact on the textile industry.

- Automated Yarn Inspection: Integration of sensors and cameras to detect yarn defects during winding, improving yarn quality and reducing waste.

- High-Speed Winding: Advanced drive systems and tension control techniques allow for increased winding speeds, boosting productivity.

- Multi-Functional Integration: Auto-Winders are being integrated with other textile machines, such as yarn dyeing and sizing machines, for seamless and efficient production lines.

- Data Monitoring and Analytics: Sensors and software collect data on winding parameters, enabling real-time monitoring and optimization of the winding process.

- Remote Monitoring: Connectivity features allow remote monitoring and control of Auto-Winders, facilitating timely maintenance and support.

10. How do you stay updated with the latest advancements in Auto-Winder technology?

- Industry Trade Shows and Conferences: Attend industry events to learn about new technologies and connect with manufacturers.

- Technical Publications and Journals: Subscribe to industry magazines and journals to stay informed about the latest developments.

- Online Forums and Discussion Groups: Participate in online communities and discussion groups related to Auto-Winder technology.

- Manufacturer Websites and Product Brochures: Regularly visit manufacturer websites and review product brochures to learn about the latest features and innovations.

- Training and Workshops: Attend training programs and workshops offered by manufacturers or industry organizations to gain hands-on experience and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Auto-Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Auto-Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Auto-Winders are responsible for operating and maintaining automatic winding machines in a production environment. They ensure that the machines are running smoothly and efficiently, and that the finished products meet quality standards.

1. Operate and maintain automatic winding machines

Auto-Winders are responsible for operating and maintaining automatic winding machines. This includes setting up the machines, loading the materials, and monitoring the progress of the winding process. They also need to be able to troubleshoot and repair any problems that may occur with the machines.

- Set up and operate automatic winding machines

- Load materials into the machines

- Monitor the progress of the winding process

- Troubleshoot and repair any problems that may occur with the machines

2. Inspect finished products

Auto-Winders are also responsible for inspecting finished products. This includes checking the products for defects, and ensuring that they meet quality standards. They also need to be able to identify and correct any problems that may be found with the products.

- Inspect finished products for defects

- Ensure that the products meet quality standards

- Identify and correct any problems that may be found with the products

3. Maintain a clean and organized work area

Auto-Winders are also responsible for maintaining a clean and organized work area. This includes keeping the machines and work area clean, and ensuring that all materials are properly stored. They also need to be able to follow safety procedures and regulations.

- Keep the machines and work area clean

- Ensure that all materials are properly stored

- Follow safety procedures and regulations

4. Work as part of a team

Auto-Winders often work as part of a team. They need to be able to communicate effectively with other team members, and work together to achieve common goals.

- Communicate effectively with other team members

- Work together to achieve common goals

Interview Tips

Preparing for an interview can be nerve-wracking, but it’s important to remember that the interviewer is just as interested in getting to know you as you are in getting to know them. Here are a few tips to help you ace your next interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals. It will also help you answer questions about the position and why you’re the right person for the job.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions

- Prepare examples of your skills and experience

- Practice answering questions with a friend or family member

3. Be yourself

It’s important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, be authentic, and be confident in your abilities.

- Don’t try to be someone you’re not

- Be honest and authentic

- Be confident in your abilities

4. Ask questions

Asking questions at the end of your interview shows that you’re interested in the position and the company. It also gives you a chance to learn more about the company and the culture. Prepare a few questions ahead of time, such as “What are the biggest challenges facing the company right now?” or “What’s the company’s culture like?”

- Prepare a few questions to ask the interviewer

- Ask questions about the position, the company, and the culture

- Don’t be afraid to ask for clarification if you don’t understand something

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Auto-Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.