Feeling lost in a sea of interview questions? Landed that dream interview for Autoclave Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Autoclave Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

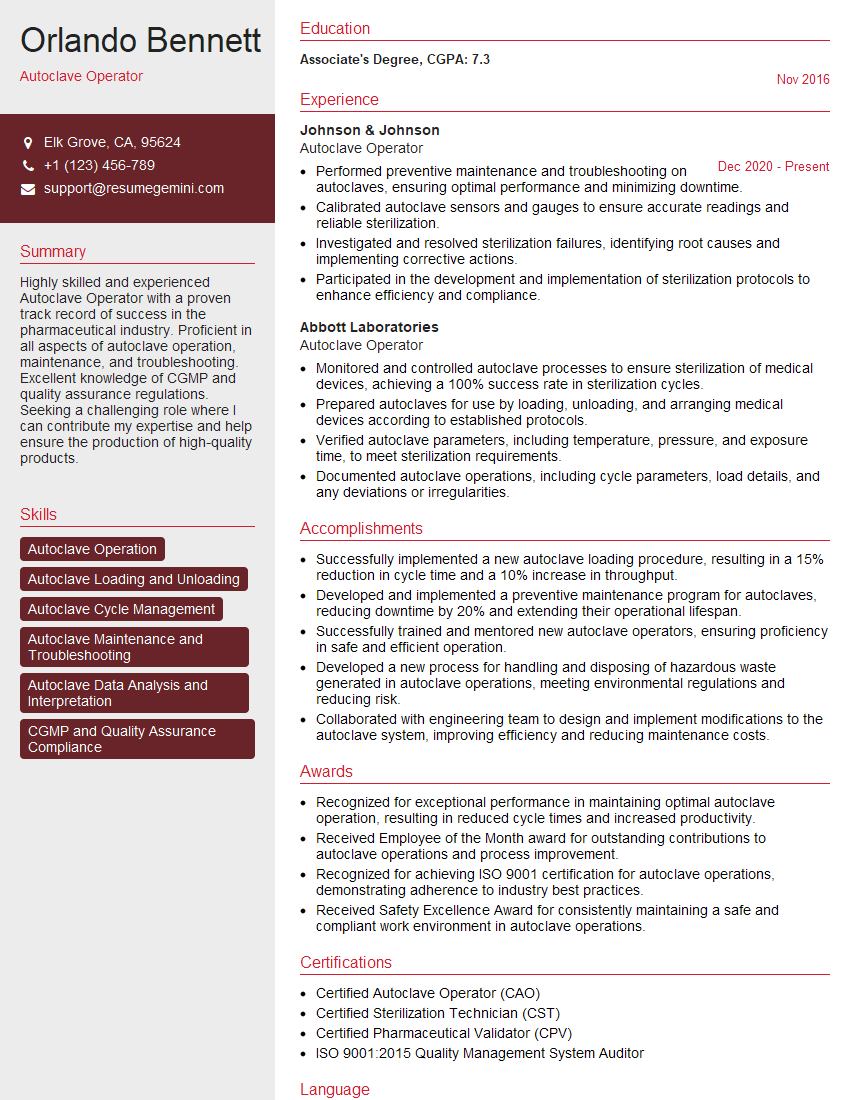

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Autoclave Operator

1. What is the importance of proper autoclave maintenance?

Proper autoclave maintenance is crucial for several reasons:

- Safety: Regular maintenance ensures that the autoclave operates safely, preventing potential accidents or injuries.

- Reliability: Well-maintained autoclaves are less likely to experience breakdowns or malfunctions, ensuring continuous availability for sterilization.

- Efficiency: Proper maintenance optimizes the autoclave’s performance, reducing sterilization time and saving energy.

- Compliance: Maintaining autoclaves according to manufacturer guidelines helps meet regulatory and accreditation standards.

2. What are the key components of an autoclave and their functions?

Chamber:

- Contains the items to be sterilized.

- Designed to withstand high pressure and temperature.

Door:

- Provides access to the chamber.

- Must seal tightly to prevent leakage.

Heater:

- Generates heat to reach sterilization temperatures.

- Typically powered by electricity or steam.

Pressure gauge:

- Monitors the pressure inside the chamber.

- Indicates when the correct sterilization conditions are reached.

3. How do you determine the correct sterilization parameters (temperature, pressure, and duration) for different materials?

I determine the correct sterilization parameters by referring to established guidelines and manufacturer recommendations:

- Temperature: Different materials have varying temperature resistance. I consult guidelines to select the optimal temperature for each type.

- Pressure: Pressure affects the sterilization efficiency. I follow guidelines to ensure adequate pressure levels.

- Duration: Sterilization time varies based on the material and the required level of sterility. I consult guidelines to determine the appropriate duration.

4. Describe the steps involved in loading and unloading an autoclave.

Loading:

- Inspect the items for any damage or contamination.

- Place items loosely in the chamber, ensuring they do not touch each other or the walls.

- Close the door securely and check the seal.

Unloading:

- Allow the autoclave to cool down to a safe temperature.

- Open the door cautiously to avoid steam release.

- Remove the sterilized items carefully, using appropriate personal protective equipment.

5. What are the common troubleshooting steps for autoclave problems?

I troubleshoot autoclave problems using the following steps:

- Check the power supply: Ensure the autoclave is connected to a power source and the circuit breaker is not tripped.

- Examine the door: Inspect the door seal for any damage or wear. A faulty seal can prevent proper sterilization.

- Review the pressure gauge: If the pressure is not building up or is below the required level, there may be a leak or a faulty pressure sensor.

- Check the temperature: Use a thermometer or temperature probe to confirm that the autoclave is reaching the desired sterilization temperature.

6. How do you ensure the safety of yourself and others when operating an autoclave?

I prioritize safety when operating an autoclave by adhering to the following measures:

- Wear personal protective equipment: Gloves, a lab coat, and safety glasses protect me from hazards such as steam or hot surfaces.

- Follow established protocols: I strictly adhere to operating instructions and safety guidelines to minimize risks.

- Inspect the autoclave regularly: I visually inspect the autoclave before each use to identify any potential issues.

- Handle sterilized items carefully: I allow items to cool down before handling to prevent burns.

7. What are the different types of autoclaves and their applications?

There are various types of autoclaves used for specific purposes:

- Gravity Displacement Autoclaves: Removes air with gravity and steam, suitable for liquids and porous materials.

- Pre-Vacuum Autoclaves: Removes air with vacuum, enabling faster sterilization of dense materials.

- Steam-Flush Autoclaves: Employs a series of steam pulses to remove air, ideal for heat-sensitive materials.

- Rapid Cycle Autoclaves: Reduces sterilization time, suitable for low-risk materials.

8. How do you monitor and maintain the performance of an autoclave?

I monitor and maintain autoclave performance through the following steps:

- Regular Inspection: I visually inspect the autoclave before each use and check for any leaks or damage.

- Performance Testing: I conduct routine performance tests using biological indicators to ensure the autoclave is effectively sterilizing items.

- Maintenance Schedule: I follow a regular maintenance schedule, including cleaning, calibration, and replacement of filters and gaskets.

- Record Keeping: I maintain records of all inspections, tests, and maintenance performed on the autoclave.

9. What is the importance of sterilization validation and how do you perform it?

Sterilization validation is crucial to verify that the autoclave consistently achieves effective sterilization:

- Ensures Patient Safety: Validation ensures that medical devices and equipment are sterile and free from microorganisms.

- Compliance: It demonstrates compliance with regulatory standards and accreditation requirements.

- Performance Monitoring: Validation helps monitor the ongoing performance of the autoclave and identify any potential issues.

I perform sterilization validation using biological indicators (BIs):

- Place BIs in challenging locations within the autoclave.

- Run the autoclave cycle.

- Incubate BIs and observe for growth to confirm sterilization effectiveness.

10. Describe any recent advancements in autoclave technology that you are familiar with.

Recent advancements in autoclave technology include:

- Automated Loading and Unloading: Systems that automate the loading and unloading of items, reducing time and labor.

- Remote Monitoring: Autoclaves with remote monitoring capabilities allow for real-time tracking and data analysis.

- Advanced Control Systems: Improved control systems enhance precision and reduce cycle times.

- Energy-Efficient Models: Autoclaves designed to minimize energy consumption and reduce environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Autoclave Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Autoclave Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Autoclave Operators are responsible for managing and operating autoclaves, which are used to sterilize equipment, supplies, and materials in various healthcare and industrial settings. Their key job responsibilities include:

1. Autoclave Operation

Loading and unloading autoclaves with materials and equipment

- Monitoring autoclave cycles to ensure proper sterilization

- Recording and maintaining autoclave records

2. Maintenance and Troubleshooting

Performing routine maintenance on autoclaves, such as cleaning, inspecting, and calibrating

- Troubleshooting and resolving autoclave malfunctions

- Following established safety protocols and procedures

3. Quality Assurance

Verifying the sterility of materials and equipment processed in autoclaves

- Monitoring equipment performance and maintaining quality standards

- Adhering to regulatory guidelines and industry best practices

4. Safety and Compliance

Ensuring safe and compliant operation of autoclaves

- Wearing appropriate personal protective gear

- Following established safety procedures and guidelines

Interview Tips

To ace an interview for an Autoclave Operator position, candidates should:

1. Research the industry and company

Gather information about the healthcare or industrial sector and the specific company you’re applying to. This will help you understand their processes, values, and the role’s relevance within the organization.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Prepare for technical questions

Be prepared to discuss your knowledge of autoclave operations, maintenance, and troubleshooting. You should also be familiar with relevant safety protocols and regulatory guidelines.

- Review your experience and practice answering questions about specific autoclave procedures.

- Prepare examples of how you have handled autoclave malfunctions in the past.

3. Emphasize safety and compliance

Autoclave Operators play a critical role in maintaining a sterile environment. Highlight your commitment to safety and your understanding of compliance regulations.

- Describe your experience with safety protocols and how you ensure compliance.

- Mention any relevant certifications or training you have completed.

4. Show enthusiasm and attention to detail

Autoclave Operators need to be detail-oriented and passionate about maintaining a sterile environment. Express your enthusiasm for the role and demonstrate your commitment to accuracy and precision.

- Share examples of how you have consistently met or exceeded sterilization standards.

- Explain how your attention to detail has contributed to successful outcomes.

Next Step:

Now that you’re armed with the knowledge of Autoclave Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Autoclave Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini