Are you gearing up for a career in Automatic Bandsaw Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Bandsaw Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

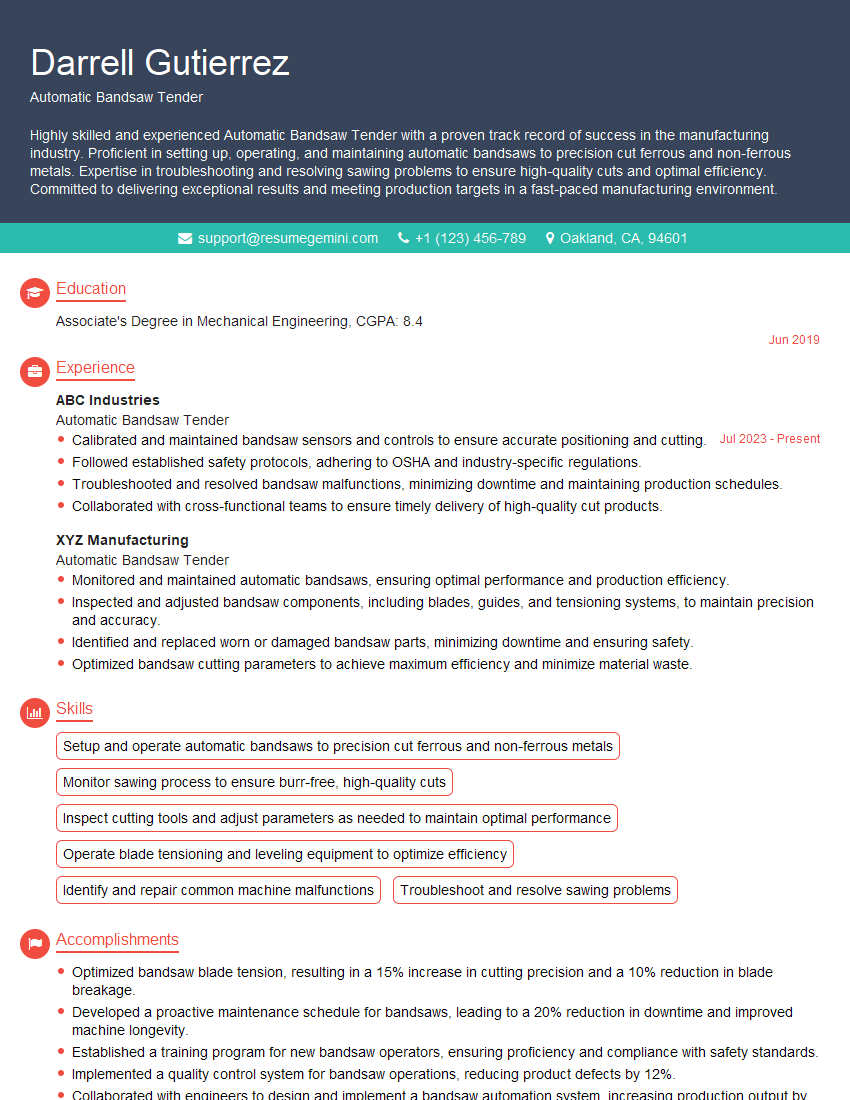

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Bandsaw Tender

1. Explain the key components of an automatic bandsaw machine and their functions?

Key components of an automatic bandsaw machine and their functions:

- Frame: Provides the structural support for the machine and houses the other components.

- Blade: The cutting element of the machine, made of a flexible, hardened steel band with teeth.

- Blade guides: Support and guide the blade as it cuts.

- Tensioning system: Maintains the proper tension on the blade during operation.

- Drive system: Provides power to the blade and moves it through the material being cut.

- Feed system: Moves the material through the cutting area.

- Control system: Monitors and controls the machine’s functions, including blade speed, feed rate, and cutting parameters.

2. Describe the different types of blades used in automatic bandsaw machines and their applications?

Types of blades used in automatic bandsaw machines and their applications:

- Bi-metal blades: Made of two layers of metal, with a high-speed steel cutting edge welded to a flexible backing material. Used for cutting a wide range of materials, including ferrous and non-ferrous metals, plastics, and wood.

- Carbon steel blades: Made of a single piece of hardened carbon steel. Used for cutting soft materials, such as aluminum, copper, and wood.

- Stainless steel blades: Made of a corrosion-resistant stainless steel alloy. Used for cutting stainless steel and other difficult-to-cut materials.

- Cermet blades: Made of a combination of ceramic and metal. Used for cutting hard and abrasive materials, such as ceramics, composites, and titanium.

3. What are the safety precautions that must be taken when operating an automatic bandsaw machine?

Safety precautions for operating an automatic bandsaw machine:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure that the machine is properly guarded and that all safety devices are in place and functioning properly.

- Never operate the machine with the blade exposed or unguarded.

- Keep your hands and other body parts away from the moving blade.

- Do not attempt to remove or adjust the blade while the machine is running.

- Always use the proper blade for the material being cut.

- Follow manufacturer’s instructions for blade tension, feed rate, and cutting parameters.

4. How do you troubleshoot common problems with automatic bandsaw machines, such as blade breakage, poor cutting quality, and vibration?

Troubleshooting common problems with automatic bandsaw machines:

Blade breakage

- Check blade tension

- Ensure blade is sharp and free of damage

- Adjust feed rate or cutting parameters

- Check for material defects or inconsistencies

Poor cutting quality

- Ensure blade is sharp and free of damage

- Adjust blade tension

- Check blade guides for wear or damage

- Check feed rate and cutting parameters

Vibration

- Check blade tension

- Ensure blade guides are properly adjusted

- Inspect machine for loose or worn components

- Check for material defects or inconsistencies

5. What are the best practices for maintaining automatic bandsaw machines to ensure optimal performance and longevity?

Best practices for maintaining automatic bandsaw machines:

- Clean the machine regularly to remove dust, chips, and other contaminants.

- Inspect the blade regularly for wear or damage and replace it as needed.

- Check and adjust blade tension according to manufacturer’s specifications.

- Lubricate moving parts as per manufacturer’s recommendations.

- Calibrate the machine regularly to ensure accurate cutting.

- Keep a maintenance log to track inspections, repairs, and other maintenance activities.

6. Can you explain the process of setting up an automatic bandsaw machine for a specific cutting job?

Process of setting up an automatic bandsaw machine for a specific cutting job:

- Select the appropriate blade for the material and cutting parameters.

- Install the blade and adjust the tension according to manufacturer’s specifications.

- Set the feed rate and cutting parameters based on the material and desired cut quality.

- Secure the material in the cutting area and align it properly.

- Start the machine and monitor the cutting process closely.

- Make adjustments as needed to optimize cutting performance.

7. What are the different types of materials that can be cut using an automatic bandsaw machine?

Materials that can be cut using an automatic bandsaw machine:

- Ferrous metals (e.g., steel, iron)

- Non-ferrous metals (e.g., aluminum, copper, brass)

- Plastics

- Wood

- Composites

- Ceramics

8. What are the key factors that affect the cutting performance of an automatic bandsaw machine?

Factors affecting the cutting performance of an automatic bandsaw machine:

- Blade sharpness and condition

- Blade tension

- Feed rate

- Cutting parameters (e.g., speed, pressure)

- Material properties

- Machine condition and maintenance

9. How do you minimize material waste and ensure accuracy when cutting with an automatic bandsaw machine?

Minimizing material waste and ensuring accuracy when cutting with an automatic bandsaw machine:

- Use the correct blade for the material and cutting parameters.

- Set the feed rate and cutting parameters carefully.

- Secure the material properly to prevent movement during cutting.

- Use a sharp blade and adjust the tension according to manufacturer’s specifications.

- Calibrate the machine regularly to ensure accurate cutting.

10. What are some advanced features and technologies used in modern automatic bandsaw machines?

Advanced features and technologies used in modern automatic bandsaw machines:

- CNC (computer numerical control) capabilities

- Automatic blade tensioning systems

- Variable speed drives

- Material handling systems

- Laser cutting guides

- Data collection and monitoring systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Bandsaw Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Bandsaw Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Automatic Bandsaw Tender is responsible for operating and maintaining automated bandsaw machines, ensuring the efficient production of cut metal or other materials.

1. Operating Automated Bandsaw Machines

The incumbent will monitor and operate automated bandsaw machines, including loading and unloading raw materials, adjusting machine settings, and troubleshooting to ensure optimal performance.

- Following established operating procedures for automatic bandsaw machines.

- Monitoring production rates and adjusting machine parameters to optimize efficiency.

2. Maintaining Equipment

The Automatic Bandsaw Tender will be responsible for maintaining the automated bandsaw machines, performing regular inspections, lubrication, and adjustments to prevent breakdowns and ensure smooth operation.

- Conducting routine inspections and preventive maintenance on automatic bandsaw machines.

- Replacing or repairing worn or damaged parts to maintain equipment in good working condition.

3. Quality Control

The Automatic Bandsaw Tender will be responsible for ensuring the quality of the cut materials. This will involve inspecting cut pieces for defects, adherence to specifications, and ensuring that they meet the required standards.

- Inspecting cut materials for dimensional accuracy, surface finish, and other quality specifications.

- Identifying and correcting any non-conformances or defects in the cut materials.

4. Production Reporting

The Automatic Bandsaw Tender will be responsible for tracking and reporting on production output, machine performance, and any issues encountered. This will help in identifying areas for improvement and ensuring efficient operation.

- Monitoring and recording production data, including throughput rates and downtime.

- Identifying and reporting any issues or bottlenecks that impact machine performance.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Automatic Bandsaw Tender position:

1. Research the Company and Role

Take the time to research the company and the specific role you are applying for. Understand the company’s values, mission, and industry. This will help you tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the position.

2. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely, highlighting your strengths and how they align with the job requirements.

- Example Question:

- Tell us about your experience in operating and maintaining automated bandsaw machines.

3. Quantify Your Experience

Whenever possible, quantify your experience and accomplishments to provide concrete evidence of your skills and abilities. Use specific numbers, metrics, or percentages to demonstrate your contributions and the impact of your work.

- Example Answer:

- I have operated and maintained automated bandsaw machines for the past 5 years, consistently achieving a production rate of over 100 pieces per hour while maintaining a high level of quality.

4. Highlight Your Safety Knowledge

Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment. Explain how you ensure the safe operation of automated bandsaw machines and follow all established safety regulations.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s growth plans, the specific responsibilities of the role, or any opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Automatic Bandsaw Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Bandsaw Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini