Feeling lost in a sea of interview questions? Landed that dream interview for Automatic Buffing Wheel Former but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automatic Buffing Wheel Former interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

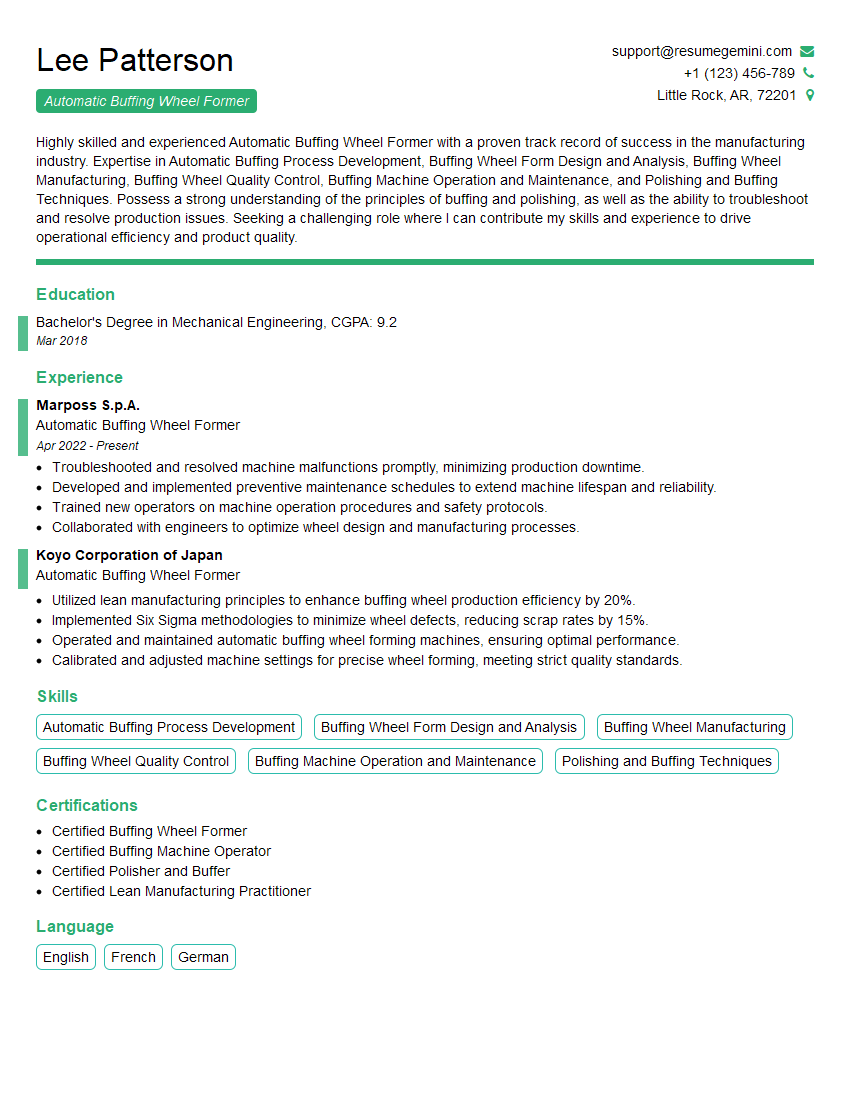

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Buffing Wheel Former

1. Explain the process of buffing wheel forming.

- The процесс of buffing wheel forming involves shaping a buffing wheel to a specific size and shape.

- This is done by using a machine that applies pressure to the wheel while it is rotating.

2. What are the different types of buffing wheels?

- There are two main types of buffing wheels: loose and sewn.

- Loose wheels are made of individual pieces of fabric that are held together by a binder.

- Sewn wheels are made of a continuous piece of fabric that is sewn together.

3. What are the factors that affect the quality of a buffing wheel?

- The quality of a buffing wheel is affected by several factors, including the type of material used, the density of the wheel, and the size and shape of the wheel.

- The material used in the wheel will determine its hardness and durability.

- The density of the wheel will determine its ability to hold compound and its resistance to wear.

- The size and shape of the wheel will determine its ability to reach different areas of the workpiece.

4. How do you maintain a buffing wheel?

- To maintain a buffing wheel, it is important to clean it regularly and to dress it as needed.

- Cleaning the wheel will remove any dirt or debris that may have accumulated on it.

- Dressing the wheel will help to restore its shape and to remove any glazing that may have occurred.

5. What are the safety precautions that should be taken when using a buffing wheel?

- When using a buffing wheel, it is important to take several safety precautions, including wearing appropriate safety gear and using the wheel in a well-ventilated area.

- Safety gear should include eye protection, ear protection, and gloves.

- The wheel should be used in a well-ventilated area to avoid inhaling any dust or debris that may be created.

6. What are the different applications for buffing wheels?

- Buffing wheels are used in a variety of applications, including metalworking, woodworking, and automotive detailing.

- In metalworking, buffing wheels are used to remove burrs and sharp edges from metal parts.

- In woodworking, buffing wheels are used to polish and finish wood surfaces.

- In automotive detailing, buffing wheels are used to polish and wax car finishes.

7. What are the advantages of using an automatic buffing wheel former?

- There are several advantages to using an automatic buffing wheel former, including increased productivity, improved quality, and reduced costs.

- Increased productivity is achieved by the ability of the machine to form wheels quickly and accurately.

- Improved quality is achieved by the machine’s ability to produce wheels with a consistent shape and size.

- Reduced costs are achieved by the machine’s ability to reduce the amount of waste generated.

8. How do you troubleshoot an automatic buffing wheel former?

- Troubleshooting an automatic buffing wheel former typically involves identifying the problem and then taking steps to correct it.

- Some common problems that may occur include the machine not forming wheels correctly, the machine not working properly, or the machine not producing wheels that meet the desired specifications.

- To troubleshoot the machine, it is important to first identify the problem and then consult the manufacturer’s instructions for specific troubleshooting steps.

9. What are the different types of materials that can be used to make buffing wheels?

- There are a variety of materials that can be used to make buffing wheels, including cotton, sisal, and canvas.

- Cotton wheels are soft and pliable, making them ideal for polishing delicate surfaces.

- Sisal wheels are made from a natural plant fiber and are more durable than cotton wheels.

- Canvas wheels are made from a heavy-duty fabric and are used for heavy-duty buffing applications.

10. What are the different grades of buffing wheels?

- Buffing wheels are available in a variety of grades, which are determined by the coarseness of the abrasive material.

- The coarseness of the abrasive material will determine the aggressiveness of the wheel.

- Coarser wheels are used for removing heavy burrs and sharp edges, while finer wheels are used for polishing and finishing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Buffing Wheel Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Buffing Wheel Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Automatic Buffing Wheel Former is responsible for operating, maintaining, and troubleshooting an automated machine that forms and sews buffing wheels used in the manufacturing of cutlery, tools, and other metal products.

1. Machine Operation

The incumbent operates the automatic buffing wheel former to produce buffing wheels of various sizes and specifications. This involves loading the machine with raw materials, setting up the forming parameters, and monitoring the machine’s operation to ensure that the wheels are formed and sewn correctly.

2. Maintenance and Troubleshooting

The incumbent performs regular maintenance on the machine, including cleaning, lubrication, and minor repairs. They also troubleshoot the machine when problems occur, diagnosing and resolving issues to ensure that the machine is operating at peak efficiency.

3. Quality Control

The incumbent inspects the finished buffing wheels to ensure that they meet the required quality standards. They check the wheels for defects, such as tears, uneven stitching, or incorrect dimensions, and reject any wheels that do not meet the specifications.

4. Production Planning

The incumbent works with the production planning team to schedule the production of buffing wheels based on customer orders. They ensure that the machine is available and that the necessary raw materials are on hand to meet production deadlines.

Interview Tips

Preparing for an interview for an Automatic Buffing Wheel Former position can help you increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Take the time to learn about the company you are applying to, as well as the specific position you are interested in. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions accordingly.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver clear and concise responses.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience operating and maintaining automated machinery, as well as your quality control skills. Be prepared to provide specific examples of your work experience that demonstrate your abilities in these areas.

4. Be Enthusiastic and Positive

The interviewer will be looking for candidates who are enthusiastic about the position and who are confident in their abilities. Be sure to convey your enthusiasm for the job and your belief that you have the skills and experience to be successful.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automatic Buffing Wheel Former role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.