Are you gearing up for an interview for a Automatic Casting-Forging Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Automatic Casting-Forging Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

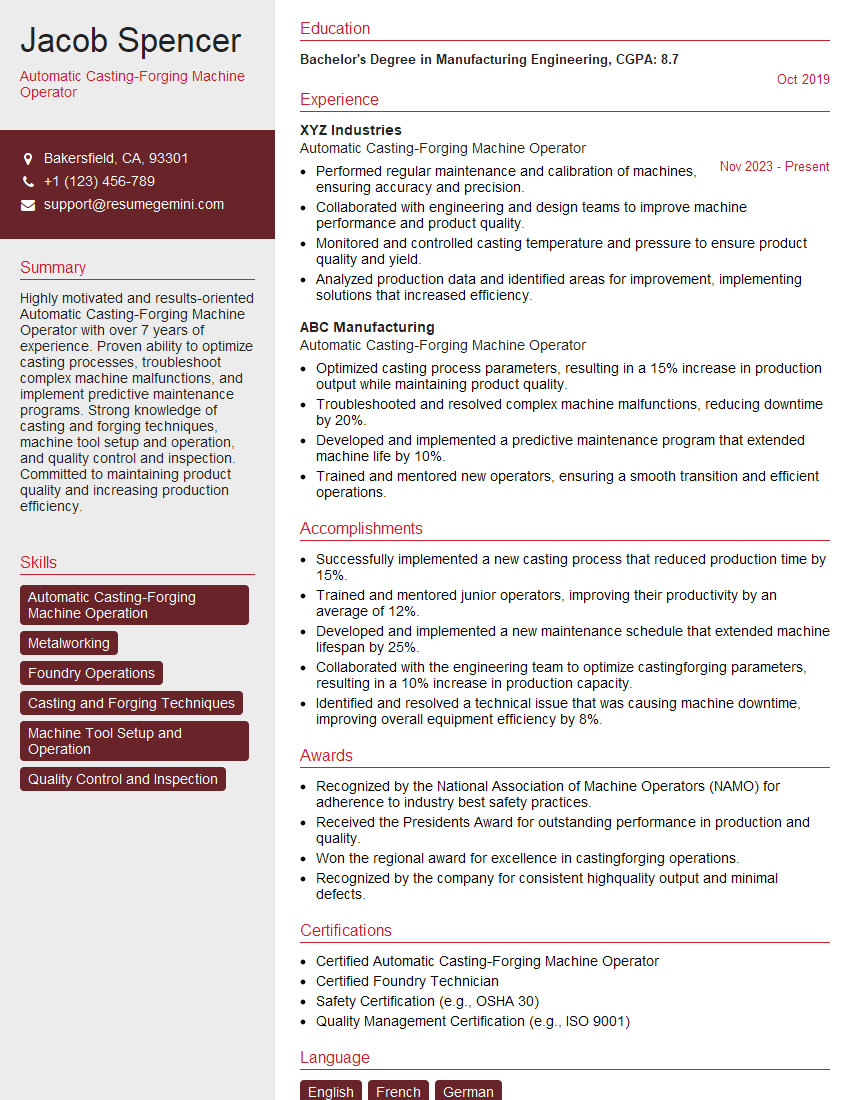

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Casting-Forging Machine Operator

1. What are the main responsibilities of an Automatic Casting-Forging Machine Operator?

- Loading raw materials into the machine and monitoring the casting and forging process

- Adjusting machine settings and parameters to ensure optimal production

- Inspecting finished products for quality and compliance with specifications

- Maintaining and troubleshooting the machine to prevent breakdowns and ensure efficient operation

2. Describe the different types of casting and forging processes used in manufacturing.

Sand Casting

- Creates complex shapes by pouring molten metal into a sand mold

- Advantages: low cost, high versatility

- Disadvantages: limited precision, rough surface finish

Investment Casting

- Produces high-precision, complex parts by creating a wax pattern and investing it in a ceramic mold

- Advantages: excellent surface finish, dimensional accuracy

- Disadvantages: high cost, limited size

Forging

- Shapes metal by applying pressure or hammering

- Types: open-die forging, closed-die forging, upset forging

- Advantages: improved strength, grain refinement, dimensional accuracy

3. What are the key safety precautions that must be followed when operating an Automatic Casting-Forging Machine?

- Wearing appropriate personal protective equipment (PPE) including safety glasses, gloves, and earplugs

- Ensuring that the machine is properly grounded and electrically safe

- Keeping the work area clean and free of tripping hazards

- Following established operating procedures and avoiding unauthorized modifications to the machine

4. How do you ensure the quality of finished products produced by the Automatic Casting-Forging Machine?

- Establishing and maintaining quality control standards

- Regularly inspecting finished products for defects and non-conformities

- Calibrating and maintaining measurement equipment

- Documenting inspection results and taking corrective action when necessary

5. What are the common maintenance tasks required for an Automatic Casting-Forging Machine?

- Lubricating moving parts and components

- Checking and adjusting fluid levels

- Inspecting electrical connections and wiring

- Replacing worn or damaged parts

- Performing regular cleaning and calibration

6. How do you troubleshoot common problems that may occur during the operation of an Automatic Casting-Forging Machine?

- Identifying the symptoms of the problem

- Consulting the machine’s manual or technical documentation

- Checking for loose connections, leaks, or other visible issues

- Using diagnostic tools or software to pinpoint the problem

- Taking appropriate steps to resolve the issue, such as replacing a faulty part or adjusting settings

7. Describe your experience in working with different alloys and metals.

- List the specific alloys and metals you have worked with

- Describe the properties and characteristics of each alloy or metal

- Explain how you adjust your casting and forging techniques to accommodate different alloys or metals

8. What methods do you use to optimize the efficiency and productivity of an Automatic Casting-Forging Machine?

- Regularly monitoring machine performance and making adjustments as needed

- Implementing preventive maintenance schedules to minimize downtime

- Optimizing production parameters, such as casting temperature and forging pressure

- Using automation and robotics to streamline processes

- Training and cross-training operators to ensure a skilled workforce

9. How do you stay updated with the latest advancements in casting and forging technologies?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with experts and vendors

- Participating in online forums and professional organizations

- Seeking opportunities for professional development and training

10. What are your career goals and aspirations?

- Expressing interest in a long-term career in the manufacturing industry

- Articulating a desire to advance to a supervisory or management role

- Describing specific skills or knowledge you aim to acquire

- Conveying your enthusiasm for the field and your commitment to continuous improvement

- Indicating how the position aligns with your career aspirations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Casting-Forging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Casting-Forging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Casting-Forging Machine Operator is entrusted with the responsibility of operating, monitoring, and maintaining automatic casting-forging machines to produce metal components. The primary duties include:

1. Machine Operation and Monitoring

Setting up and operating automatic casting-forging machines according to established specifications.

- Loading and unloading raw materials and finished products.

- Monitoring machine operations to detect any anomalies or malfunctions.

2. Maintenance and Troubleshooting

Performing scheduled maintenance and troubleshooting on machines to ensure optimal performance.

- Lubricating and cleaning machine components.

- Identifying and resolving minor malfunctions.

3. Quality Control

Inspecting and testing finished products to ensure they meet quality standards.

- Measuring and verifying dimensions and specifications.

- Identifying and rejecting defective products.

4. Safety and Compliance

Following all safety protocols and adhering to industry regulations.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area.

Interview Tips

To ace the interview for an Automatic Casting-Forging Machine Operator position, candidates should consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and the specific requirements for the Automatic Casting-Forging Machine Operator role.

- Review the job description thoroughly.

- Visit the company’s website and social media pages for additional insights.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience operating and maintaining similar casting-forging machines.

- Quantify your accomplishments and provide specific examples of your abilities.

- Demonstrate your understanding of quality control procedures and safety regulations.

3. Practice Answering Common Interview Questions

Anticipate and prepare for common interview questions related to your technical capabilities, experience, and work ethic.

- Example Outline:

- Tell me about your experience operating automatic casting-forging machines.

- How do you handle troubleshooting and resolving malfunctions?

- Describe your approach to maintaining a safe and efficient work environment.

4. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally and arrive on time for the interview.

- Business attire is typically appropriate.

- Punctuality shows respect for the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automatic Casting-Forging Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.