Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automatic Casting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

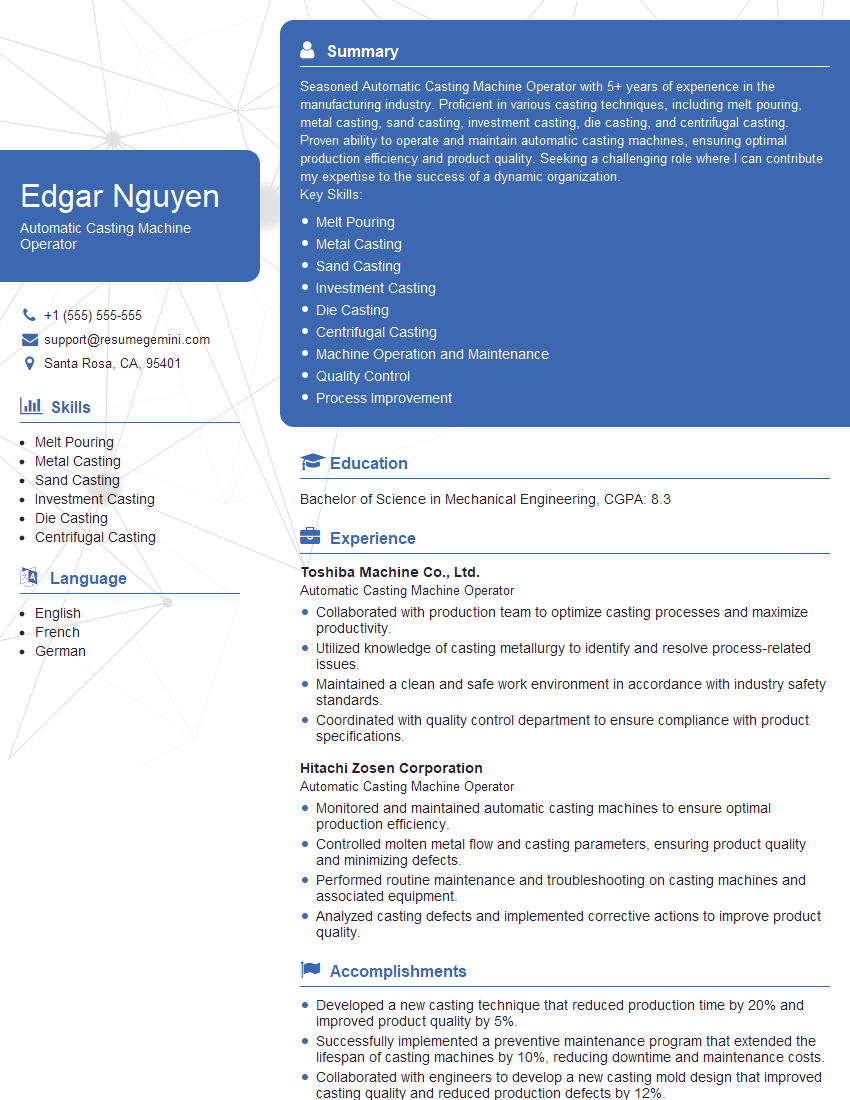

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Casting Machine Operator

1. Describe the key responsibilities of an Automatic Casting Machine Operator?

- Monitor and operate the automatic casting machine to produce metal castings

- Ensure the casting machine is in good working order and perform routine maintenance and repairs

- Set up the casting machine, including preparing the mold, melting the metal, and pouring the molten metal into the mold

- Remove finished castings from the machine and inspect them for quality

- Maintain a clean and safe work area, and follow all safety procedures

2. Explain the different types of casting processes used in automatic casting machines?

Sand casting

- In sand casting, a mold is created by packing sand around a pattern or model of the desired casting

- Molten metal is then poured into the mold, and allowed to cool and solidify

Die casting

- In die casting, molten metal is forced under high pressure into a metal mold or die

- This process produces castings with high precision and accuracy

Investment casting

- In investment casting, a wax pattern of the desired casting is created

- The wax pattern is then invested in a ceramic mold, and the wax is melted out

- Molten metal is then poured into the mold, and allowed to cool and solidify

3. What are the safety precautions that must be taken when operating an automatic casting machine?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat

- Keep the work area clean and free of tripping hazards

- Be aware of the location of fire extinguishers and other safety equipment

- Follow all operating procedures and safety guidelines

- Never operate the machine if you are under the influence of drugs or alcohol

4. How do you troubleshoot common problems with automatic casting machines?

- Check the power supply and make sure the machine is properly grounded

- Check the hydraulic and pneumatic systems for leaks or blockages

- Check the mold for any damage or wear

- Check the molten metal for the correct temperature and composition

- Refer to the machine’s operating manual for specific troubleshooting procedures

5. What are the quality control checks that you perform on finished castings?

- Visual inspection for any defects, such as cracks, voids, or inclusions

- Dimensional inspection to ensure the casting meets the specified dimensions

- Weight measurement to ensure the casting is within the specified weight range

- Hardness testing to ensure the casting has the required hardness

- Pressure testing to ensure the casting is free of leaks

6. How do you maintain and calibrate the automatic casting machine?

- Follow the manufacturer’s recommended maintenance schedule

- Clean and lubricate the machine regularly

- Inspect the machine for any signs of wear or damage

- Calibrate the machine according to the manufacturer’s instructions

- Keep a detailed maintenance log

7. What are the different types of materials that can be cast using an automatic casting machine?

- Ferrous metals, such as iron, steel, and stainless steel

- Non-ferrous metals, such as aluminum, copper, and brass

- Alloys, such as bronze, pewter, and solder

8. What are the advantages of using an automatic casting machine over manual casting?

- Increased productivity

- Improved quality and accuracy

- Reduced labor costs

- Safer working environment

9. What are the challenges of working as an Automatic Casting Machine Operator?

- Working in a hot and noisy environment

- Dealing with heavy and potentially hazardous materials

- Keeping up with the demands of production

- Working overtime and weekends

10. Why are you interested in working as an Automatic Casting Machine Operator?

- I am interested in learning more about the casting process

- I am looking for a challenging and rewarding career

- I am confident that I have the skills and experience to be successful in this role

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Casting Machine Operators are responsible for the safe and efficient operation of automatic casting machines. They ensure that the machines are properly set up and maintained, and that the castings are produced according to specifications.

1. Set up and operate automatic casting machines

Automatic Casting Machine Operators are responsible for setting up and operating automatic casting machines. This involves:

- Loading the machine with raw materials

- Setting the machine’s operating parameters

- Monitoring the machine’s operation

- Making adjustments to the machine’s settings as needed

2. Inspect castings

Automatic Casting Machine Operators are responsible for inspecting castings to ensure that they meet specifications. This involves:

- Visually inspecting castings for defects

- Measuring castings to ensure that they are within tolerance

- Testing castings to ensure that they meet performance requirements

3. Maintain casting machines

Automatic Casting Machine Operators are responsible for maintaining casting machines. This involves:

- Cleaning and lubricating machines

- Replacing worn parts

- Making minor repairs

- Performing preventive maintenance tasks

4. Troubleshoot problems

Automatic Casting Machine Operators are responsible for troubleshooting problems with casting machines. This involves:

- Identifying the source of the problem

- Determining the best course of action to solve the problem

- Implementing the solution and testing to ensure that the problem is resolved

Interview Tips

Here are some tips for acing your interview for an Automatic Casting Machine Operator position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will show the interviewer that you are interested in the job and that you have taken the time to learn about the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience operating automatic casting machines. Be prepared to talk about your skills and knowledge, and to provide examples of your work.

4. Be prepared to talk about your safety knowledge

Safety is very important in the casting industry. Be prepared to talk about your safety knowledge and experience, and to explain how you would ensure the safety of yourself and others in the workplace.

5. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. It is also a good time to ask questions that demonstrate your interest in the job, such as “What are the biggest challenges facing the company right now?” or “What are the opportunities for advancement within the company?”.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automatic Casting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.