Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Cigar Wrapper Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Cigar Wrapper Tender so you can tailor your answers to impress potential employers.

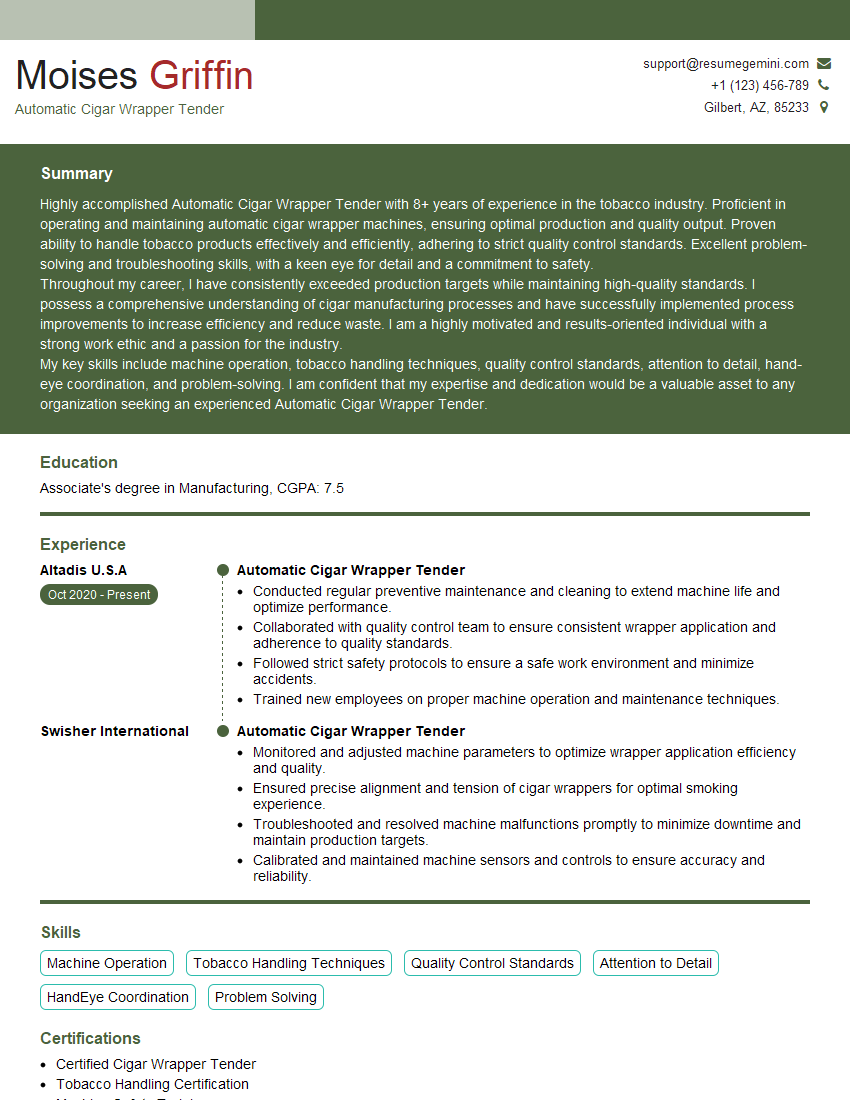

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Cigar Wrapper Tender

1. What specific actions do you take to maintain the quality of the cigar wrapper?

In my previous role, I implemented a rigorous quality control process that involved:

- Regularly inspecting incoming raw materials to ensure they met specifications.

- Monitoring the production process to identify any deviations that could affect quality.

- Conducting random checks on finished products to verify consistency and adherence to standards.

2. Can you describe the role of temperature and humidity in the aging process of cigar wrappers?

Environmental Control

- Temperature: Optimal temperature ranges are maintained to prevent damage to the wrappers and ensure proper aging.

- Humidity: Regulated humidity levels create the ideal environment for controlled moisture content and prevent excessive drying or over-hydration.

Aging Process

- Enhancing Flavor: Controlled conditions promote the development of complex flavors and aromas in the wrappers.

- Improving Suppleness: Proper aging enhances the flexibility and malleability of the wrappers, making them easier to work with.

3. How do you troubleshoot issues related to the cigar wrapper tender?

When troubleshooting issues with the cigar wrapper tender, I follow these steps:

- Identify the problem accurately by observing symptoms and analyzing data.

- Check for common causes such as improper machine settings, worn components, or blockages.

- Inspect electrical connections, sensors, and other key components for malfunctions.

- Consult technical manuals or consult with experienced colleagues to resolve complex issues.

- Implement corrective actions and monitor the machine’s performance to ensure the problem is resolved.

4. What are the safety protocols you follow when operating the cigar wrapper tender?

To ensure safety when operating the cigar wrapper tender, I adhere to the following protocols:

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Keep the work area clean and free of tripping hazards or other potential risks.

- Be aware of moving parts and remain at a safe distance from the machine’s operation.

- Report any safety concerns or potential hazards to supervisors immediately.

5. What is your experience with calibrating and maintaining the sensors used in the cigar wrapper tender?

In my previous role, I was responsible for calibrating and maintaining the sensors used in the cigar wrapper tender:

- Temperature Sensors: Calibrated temperature sensors to ensure accurate temperature readings within the aging environment.

- Humidity Sensors: Adjusted humidity sensors to maintain optimal humidity levels and prevent fluctuations.

- Tension Sensors: Checked and calibrated tension sensors to ensure proper alignment and tension of the cigar wrappers.

- Adhered to calibration schedules and documented all calibration activities for quality control purposes.

6. How do you ensure the efficient operation of the cigar wrapper tender and minimize downtime?

To ensure efficient operation and minimize downtime, I:

- Perform regular preventive maintenance checks to identify and address potential issues early on.

- Monitor the machine’s performance through data analysis and identify areas for improvement or optimization.

- Train operators on proper machine usage and troubleshooting techniques to prevent misuse.

- Maintain a stock of spare parts and components to facilitate prompt repairs in case of unexpected breakdowns.

- Collaborate with maintenance teams to ensure timely repairs and minimize production interruptions.

7. Can you explain the process of preparing and loading the cigar leaves into the cigar wrapper tender?

Preparing and loading the cigar leaves into the cigar wrapper tender involves the following steps:

- Selection: Selecting high-quality cigar leaves based on size, texture, and maturity.

- Sorting: Grading and sorting leaves into different categories based on their characteristics.

- Trimming: Removing excess veins or imperfections from the leaves to ensure a smooth and even wrapping process.

- Moistening: Slightly moistening the leaves to make them pliable and easier to handle.

- Loading: Carefully loading the prepared leaves into the feeding mechanism of the tender in the correct orientation.

8. What techniques do you use to minimize waste and optimize the yield of cigar wrappers?

To minimize waste and optimize the yield of cigar wrappers, I:

- Utilize efficient cutting techniques to minimize leaf damage and maximize wrapper size.

- Inspect leaves carefully before and during the wrapping process to identify and remove any damaged or defective areas.

- Repurpose smaller or irregular-shaped leaves for other cigar components, such as filler or binder.

- Monitor wrapper thickness and adjust the tender settings accordingly to avoid over-wrapping or tearing.

- Train operators on proper handling techniques to prevent unnecessary damage to the wrappers.

9. How do you handle variations in the quality of the raw tobacco leaves used for cigar wrappers?

To handle variations in the quality of raw tobacco leaves used for cigar wrappers, I:

- Inspect incoming leaves thoroughly to identify any imperfections or defects.

- Sort and grade the leaves based on their quality and suitability for different types of cigars.

- Adjust the tender settings to accommodate different leaf thicknesses and textures.

- Monitor the wrapping process closely and make adjustments as needed to ensure consistent quality.

- Collaborate with suppliers to provide feedback on leaf quality and suggest improvements.

10. Can you describe the different types of cigar wrappers and their characteristics?

Different types of cigar wrappers include:

Connecticut Shade

- Grown under shade cloth, resulting in a mild and smooth flavor.

- Light in color with a delicate aroma.

Habano

- Darker in color, with a rich and earthy flavor.

- Originating from Cuba, known for its complexity.

Cameroon

- Medium-bodied with a spicy and nutty flavor.

- Known for its oily texture and elasticity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Cigar Wrapper Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Cigar Wrapper Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Cigar Wrapper Tender is responsible for setting up and operating an automatic cigar wrapper tender machine, which applies cigar wrappers to the filler tobacco inside a cigar.

1. Machine Operation

The tender is responsible for ensuring the machine is set up correctly and running smoothly, including:

- Loading and unloading the machine with cigar wrappers

- Monitoring the machine’s operation and making adjustments as needed

- Cleaning and maintaining the machine

2. Quality Control

The tender is also responsible for inspecting the wrappers to ensure they are of good quality and inspecting the finished product to ensure it meets the company’s standards.

- Inspecting the cigar wrappers for any tears or holes

- Inspecting the finished cigars for any defects

- Reporting any quality issues to the supervisor

3. Production

The tender is responsible for ensuring the production process runs smoothly, including:

- Ensuring the machine is running at the correct speed

- Monitoring the production line and making adjustments as needed

- Reporting any production issues to the supervisor

4. Safety

The tender is responsible for ensuring that the work area is safe for themselves and others, including:

- Following all safety rules and procedures

- Wearing appropriate safety gear

- Reporting any safety hazards to the supervisor

Interview Tips

To fully prepare for an interview for an Automatic Cigar Wrapper Tender position, it is suggested to:

1. Research the company and the position

Visit the company’s website to learn more about their history, products, and culture. Research the specific position you are applying for to understand the key responsibilities and qualifications.

- Practice answering common interview questions

- Dress professionally

2. Highlight your experience and skills

Be prepared to discuss your relevant experience and skills, such as your experience operating automatic machinery, your quality control experience, and your production experience. You may also want to highlight any safety training or certifications you have.

- Be confident and enthusiastic

- Ask questions

3. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. Some good questions to ask include:

- What are the company’s goals for the future?

- What are the biggest challenges facing the company?

- What is the company culture like?

4. Follow up

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank the interviewer for their time.

- Follow up with the interviewer

- Be patient

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automatic Cigar Wrapper Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.