Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automatic Drill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

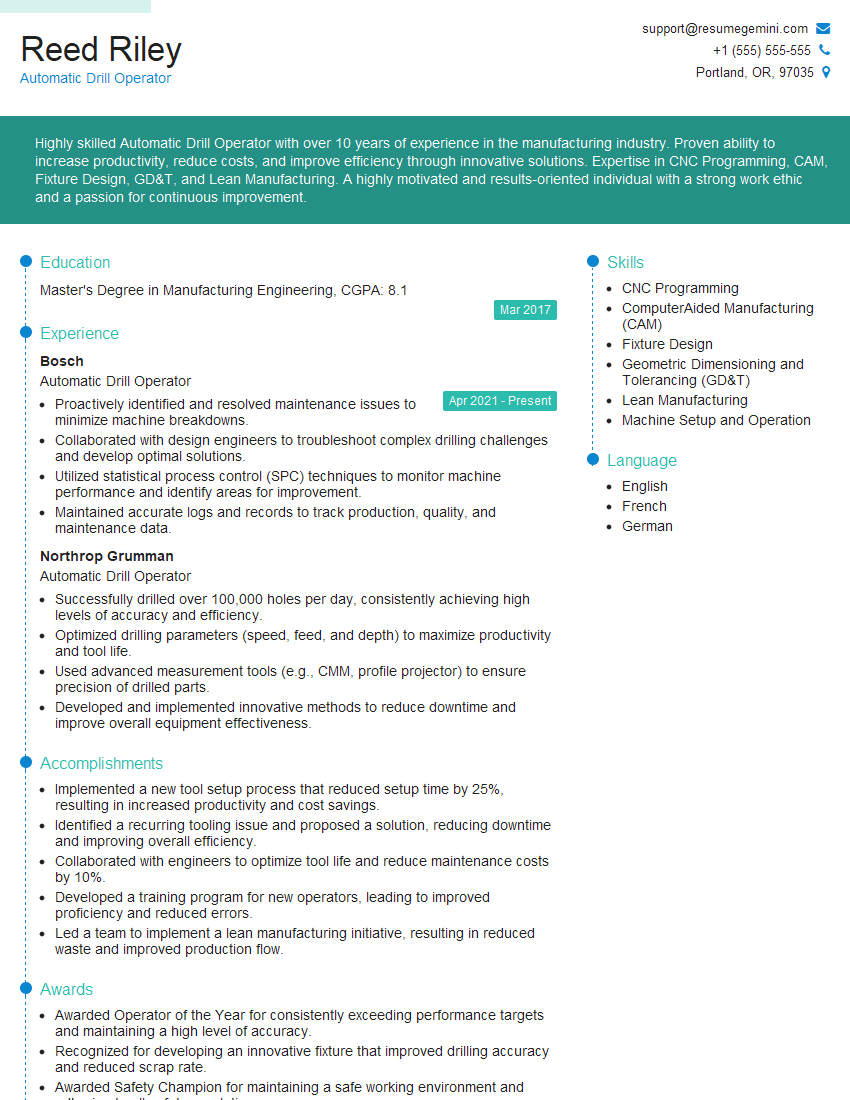

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Drill Operator

1. Explain the primary responsibilities of an Automatic Drill Operator?

- Monitoring and controlling automatic drilling machines to drill holes in various materials.

- Setting up and operating drill presses, ensuring proper alignment and drill bit selection.

- Inspecting and maintaining equipment to ensure optimal performance and safety.

2. Describe the different types of drilling machines used in your previous role?

Manual drilling machines

- Hand-held drills for small and portable operations.

- Benchtop drills for precision drilling in stationary workpieces.

CNC drilling machines

- Computer-controlled machines for automated drilling processes.

- Equipped with automatic tool changers for efficient operation.

3. How do you ensure accuracy and precision when drilling holes?

- Using precision measuring tools (e.g., calipers, micrometers) to set up drill presses accurately.

- Selecting the appropriate drill bit size and material for the specific application.

- Inspecting workpieces regularly to ensure conformance to specifications.

4. What is your experience with troubleshooting and resolving automated drilling issues?

- Identifying common problems (e.g., tool breakage, alignment issues, material defects).

- Applying practical solutions and using diagnostic tools to resolve malfunctions.

- Documenting and reporting any maintenance or repair issues for future reference.

5. Describe your knowledge of drilling machine safety protocols?

- Wearing appropriate personal protective equipment (PPE) (e.g., safety glasses, gloves).

- Ensuring the machine is properly grounded and securely fastened to prevent movement.

- Following established operating procedures and avoiding unauthorized modifications to the equipment.

6. What techniques do you use to optimize drilling efficiency?

- Using high-quality drill bits and cutting fluids to minimize tool wear and improve hole quality.

- Employing appropriate feed rates and speeds to maximize drilling efficiency and workpiece integrity.

- Regularly cleaning and maintaining equipment to ensure optimal performance and reduce downtime.

7. How do you stay updated with the latest advancements in automatic drilling technology?

- Attending industry events and conferences to learn about new technologies and trends.

- Reading trade publications and technical journals to stay informed about industry best practices.

- Consulting with experts and colleagues to share knowledge and learn from others.

8. Describe a situation where you encountered a challenging drilling project and how you overcame it?

- Explain the specific challenges faced (e.g., material hardness, complex hole geometry).

- Highlight the innovative solutions implemented to address the challenges.

- Emphasize the successful outcome and any lessons learned from the experience.

9. How do you handle working independently and as part of a team in a manufacturing environment?

- Demonstrate strong self-motivation and ability to work autonomously.

- Highlight effective communication and collaboration skills when working in a team setting.

- Discuss how you contribute to team success and maintain a positive work environment.

10. Why are you interested in joining our organization as an Automatic Drill Operator?

- Express enthusiasm for the organization’s mission and industry reputation.

- Highlight your alignment with the company’s values and commitment to excellence.

- Explain how your skills and experience can contribute to the team’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Drill Operators are responsible for operating and maintaining automated drilling machines in a manufacturing setting. Their key responsibilities include:

1. Operating Automated Drilling Machines

Operate automated drilling machines to produce holes in various materials, such as metal, wood, and plastic, according to specified dimensions and tolerances.

- Set up and adjust drilling machines, including selecting the appropriate drill bits, speeds, and feeds.

- Load and unload materials into the machines, ensuring proper alignment and positioning.

- Monitor the drilling process, ensuring that holes are drilled to the correct depth, diameter, and location.

- Make adjustments to the machine settings as needed to maintain accuracy and efficiency.

2. Maintaining Equipment

Perform basic maintenance and repairs on automated drilling machines, such as cleaning, lubricating, and replacing worn parts.

- Identify and troubleshoot mechanical or electrical issues with the machines.

- Follow established maintenance schedules to ensure optimal performance.

- Report any major issues or repairs to the appropriate supervisor.

3. Quality Control

Inspect drilled parts to ensure they meet specified quality standards.

- Use measuring tools and gauges to verify the accuracy and precision of the holes.

- Identify and reject any defective parts.

- Maintain records of quality inspections and report any deviations from standards.

4. Safety Compliance

Follow all safety regulations and procedures while operating automated drilling machines.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of hazards.

- Report any unsafe conditions or practices to the supervisor.

Interview Tips

To ace an interview for an Automatic Drill Operator position, it’s important to prepare thoroughly and highlight your relevant skills and experience.

1. Research the Company and Position

Learn about the company’s background, industry, and specific products or services. Understand the role of the Automatic Drill Operator within the organization.

- Review the job description carefully and identify the key responsibilities and qualifications.

- Visit the company’s website, LinkedIn page, and other online resources to gather more information.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating automated drilling machines and performing quality control inspections.

- Quantify your accomplishments whenever possible. For example, “Increased production efficiency by 15% by optimizing drilling machine settings.”

- Provide specific examples of how you have maintained and repaired automated drilling equipment.

- Showcase your understanding of safety regulations and best practices.

3. Demonstrate Attention to Detail and Accuracy

Automatic Drill Operators must be able to work precisely and accurately. Highlight your ability to follow instructions, meet specifications, and maintain high quality standards.

- Share examples of projects where you paid close attention to detail and achieved successful outcomes.

- Explain how you use measuring tools and gauges to ensure the accuracy of your work.

4. Prepare for Common Interview Questions

Be prepared to answer common interview questions related to your skills, experience, and work style. Examples of questions you may encounter include:

- “Tell me about your experience operating automated drilling machines.”

- “Describe a situation where you had to troubleshoot a problem with an automated drilling machine.”

- “How do you ensure that drilled parts meet quality standards?”

5. Be Enthusiastic and Professional

Show your enthusiasm for the position and the manufacturing industry. Dress professionally, maintain eye contact, and speak clearly and confidently during the interview.

- Prepare questions to ask the interviewer, which demonstrates your engagement and interest in the role.

- Thank the interviewer for their time and consideration at the end of the interview.

Next Step:

Now that you’re armed with the knowledge of Automatic Drill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Drill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini