Are you gearing up for a career in Automatic Drilling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Drilling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

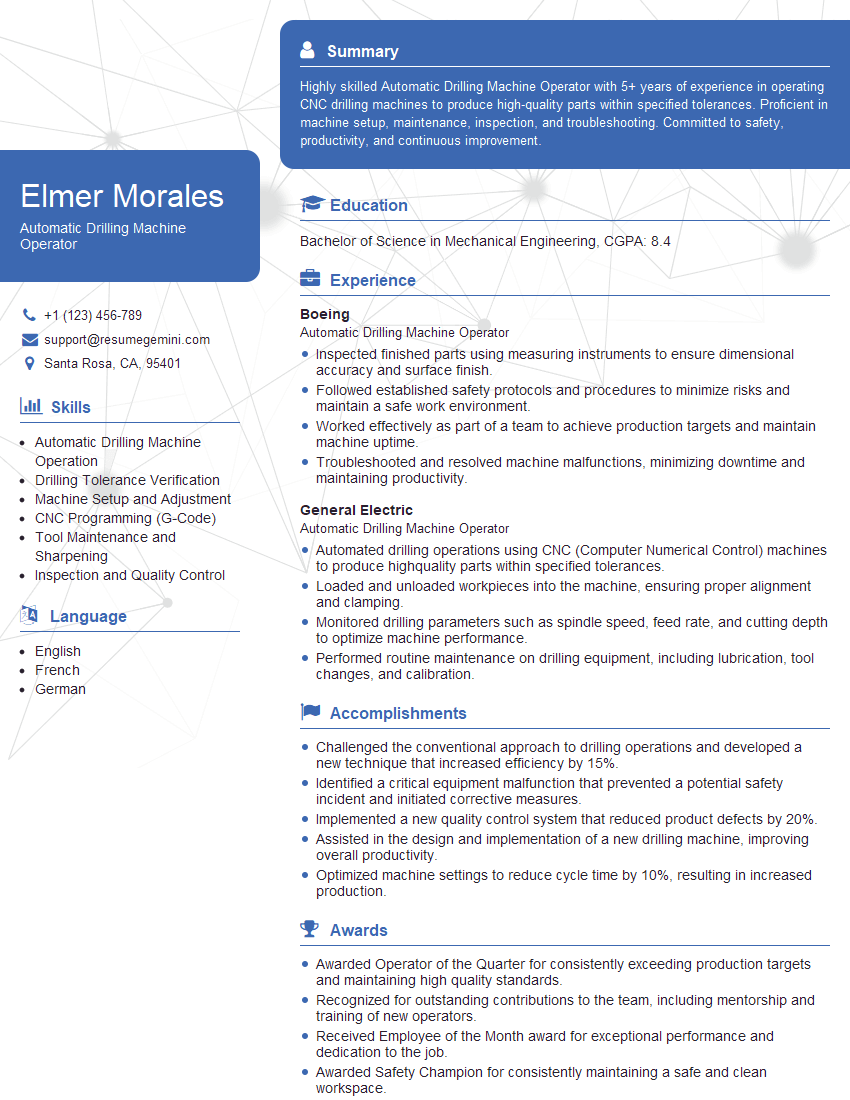

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Drilling Machine Operator

1. Describe the key responsibilities of an Automatic Drilling Machine Operator?

- Operate and maintain automatic drilling machines to produce precision holes in various materials.

- Set up and adjust machines according to specified drilling parameters, including drill speed, feed rate, and depth.

- Load and unload workpieces, ensuring proper alignment and clamping.

- Monitor machine operation, adjust settings as needed, and identify potential problems.

- Maintain a clean and organized work area, adhering to safety regulations.

2. What are the different types of drills used in automatic drilling machines?

- Twist drills: General-purpose drills for most applications.

- Step drills: Create holes of multiple diameters in a single operation.

- Gun drills: Long, slender drills for deep hole applications.

- Indexable drills: Drills with replaceable cutting inserts for increased efficiency.

- Carbide drills: High-performance drills for hard or abrasive materials.

3. How do you ensure the accuracy and precision of drilling operations?

To ensure accuracy and precision, I employ various techniques:

- Properly aligning and clamping workpieces before drilling.

- Selecting the correct drill size and type for the material and hole requirements.

- Using sharp and well-maintained drills.

- Adjusting machine settings accurately, including spindle speed, feed rate, and depth.

- Monitoring the drilling process and making adjustments as needed.

4. What troubleshooting techniques do you use when encountering machine problems?

When faced with machine problems, I follow these troubleshooting techniques:

- Identify potential causes by observing machine operation and error messages.

- Check for loose or damaged components, such as belts, pulleys, or electrical connections.

- Examine cutting tools for wear or breakage.

- Refer to machine manuals or consult with experienced operators or supervisors.

- Perform basic troubleshooting steps, such as power cycling or cleaning sensors.

5. How do you maintain automatic drilling machines for optimal performance?

- Regularly cleaning and lubricating machine components.

- Inspecting and replacing worn or damaged parts promptly.

- Calibrating and adjusting machines according to manufacturer’s specifications.

- Performing preventive maintenance tasks, such as changing filters and checking oil levels.

- Adhering to recommended maintenance schedules.

6. Describe the safety precautions you observe when operating automatic drilling machines?

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensuring that the machine is properly grounded and electrically safe.

- Clearing the work area of any obstructions or materials that could cause accidents.

- Using sharp and securely fastened cutting tools.

- Following established lockout/tagout procedures when servicing or repairing machines.

7. What is the difference between through-hole and blind-hole drilling?

Through-hole drilling:

- Creates holes that pass completely through the workpiece.

- Typically used for applications where a fastener or shaft needs to be inserted.

Blind-hole drilling:

- Creates holes that do not penetrate the entire workpiece.

- Often used for applications where a threaded insert or tapped hole is required.

8. Explain the process of setting up an automatic drilling machine for a new job.

- Review the job specifications and determine the required hole parameters.

- Select the appropriate drill and drill bits.

- Set up the machine according to the specified drilling parameters.

- Load and secure the workpiece on the machine table.

- Perform a test run to verify the accuracy and quality of the drilling operation.

9. What are the common causes of drill breakage and how can you prevent them?

Causes of drill breakage:

- Using dull or damaged drills.

- Excessive drilling forces due to incorrect feed rates or spindle speeds.

- Improper alignment of the drill with the workpiece.

- Vibration or chatter during the drilling process.

- Overloading the drill with excessive material removal.

Preventive measures:

- Use sharp and well-maintained drills.

- Adjust drilling parameters to suit the material and drill size.

- Ensure proper alignment of the drill and workpiece.

- Reduce vibration by using sharp drills and maintaining the machine in good condition.

- Avoid overloading the drill by using appropriate feed rates and spindle speeds.

10. How do you handle deviations from specified drilling parameters during a production run?

- Identify the cause of the deviation by observing machine operation and workpiece quality.

- Adjust machine settings or change cutting tools as needed.

- Perform additional inspections to ensure that the drilling operation is meeting specifications.

- Document any deviations and take corrective action to prevent future occurrences.

- Inform supervisors about significant deviations or potential quality concerns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Drilling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Drilling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Drilling Machine Operators play a vital role in the manufacturing process, using specialized machines to create precise holes in various materials.

1. Machine Operation and Maintenance

Operate and maintain automatic drilling machines, ensuring efficient and accurate operation.

- Set up machines according to specifications, including loading materials and selecting drill bits.

- Monitor machine operation, adjusting settings and making necessary adjustments to maintain quality.

- Perform routine maintenance and inspections to prevent malfunctions and ensure optimal performance.

2. Quality Control

Inspect drilled holes to ensure they meet dimensional and quality standards.

- Use measuring instruments to verify hole dimensions and surface finish.

- Identify and correct any defects or deviations from specifications.

- Maintain records of quality checks and report any issues to supervisors.

3. Production Efficiency

Optimize machine operation to maximize production efficiency.

- Analyze production data and identify areas for improvement.

- Implement process changes to reduce cycle times and increase output.

- Collaborate with other operators and technicians to ensure smooth production flow.

4. Safety Compliance

Adhere to all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE) and maintain a clean and organized work area.

- Follow lockout/tagout procedures and report any hazards or potential safety risks.

- Receive and complete safety training as required.

Interview Tips

Preparing for an interview for an Automatic Drilling Machine Operator position requires thorough knowledge of the job responsibilities and effective interview techniques.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends.

- This demonstrates your interest in the position and the company.

- Use online resources, company websites, and industry publications to gather information.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your experience with automatic drilling machines and related skills.

- Provide specific examples of your accomplishments in previous roles.

- Quantify your achievements whenever possible, using metrics and data to demonstrate your impact.

3. Demonstrate Attention to Detail and Precision

Consistently highlight your meticulous approach to work and your commitment to accuracy.

- Explain your quality control processes and provide examples of how you have identified and corrected errors.

- Discuss your use of measuring instruments and your ability to meet tight tolerances.

4. Emphasize Safety and Compliance

As safety is paramount in this role, convey your understanding of and adherence to safety protocols.

- Describe your experience with PPE, lockout/tagout procedures, and hazard identification.

- Mention any safety training or certifications you have obtained.

5. Practice Active Listening and Communication

Be attentive to the interviewer’s questions and provide clear, concise answers.

- Ask thoughtful questions to clarify job responsibilities and expectations.

- Maintain eye contact, speak confidently, and use appropriate body language to convey your professionalism.

Next Step:

Now that you’re armed with the knowledge of Automatic Drilling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Drilling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini