Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Dry Starch Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Dry Starch Operator so you can tailor your answers to impress potential employers.

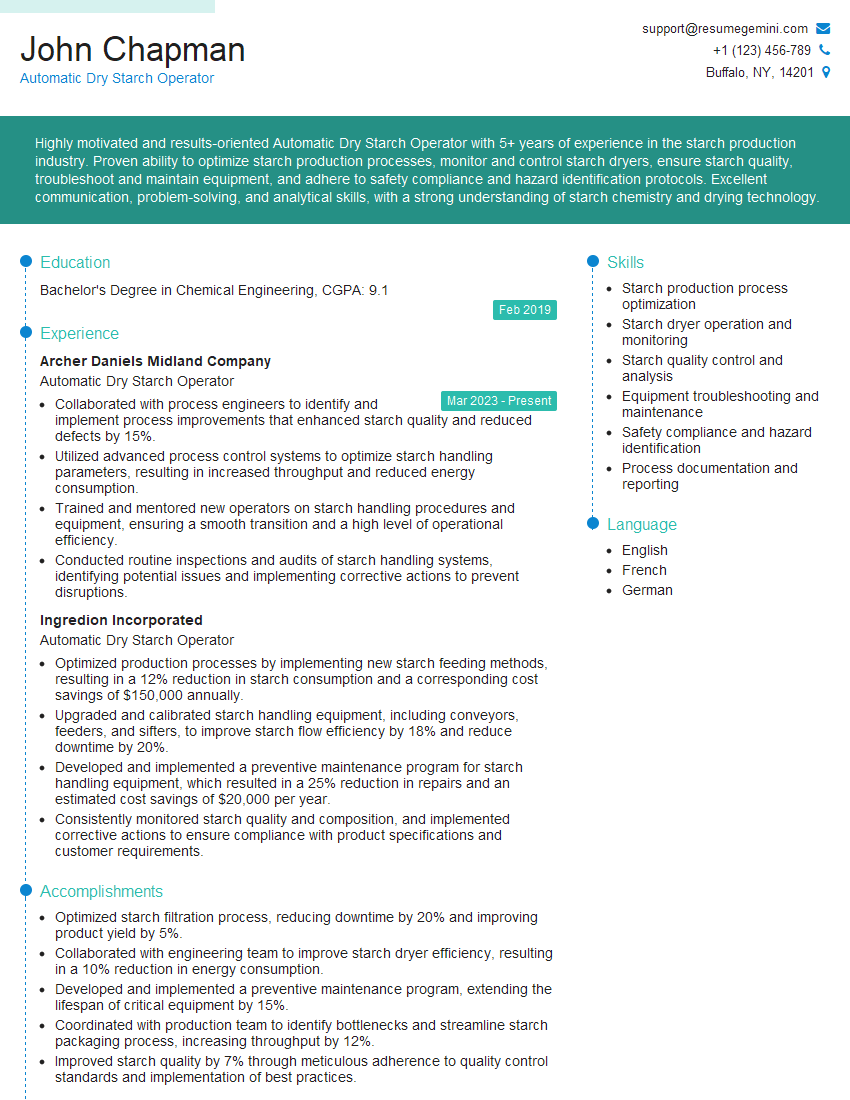

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Dry Starch Operator

1. Explain the role of a pneumatic conveying system in an automatic dry starch operation?

The pneumatic conveying system is a crucial part of an automatic dry starch operation, as it is responsible for transporting the starch from the storage silos to the process equipment. The system typically consists of a blower, which creates the airflow to move the starch, and a network of pipes and ducts to transport the starch to the desired locations. The system is designed to maintain a constant flow of starch, ensuring that the process equipment has a consistent supply of material to work with.

2. Describe the process of starch gelatinization and what factors affect it?

Starch gelatinization is the process of heating starch in the presence of water, causing it to absorb water and swell. The gelatinized starch becomes more viscous and forms a gel-like structure. The factors that affect starch gelatinization include:

– Starch type: Different types of starch have different gelatinization temperatures and rates.

– Temperature: The gelatinization temperature is the temperature at which the starch begins to gelatinize.

– Water content: The amount of water present affects the rate of gelatinization and the viscosity of the gel.

– pH: The pH of the water can affect the gelatinization temperature and the viscosity of the gel.

3. How do you maintain the quality of dry starch during storage and handling?

Maintaining the quality of dry starch during storage and handling is crucial to prevent spoilage and ensure optimal performance in the production process. Here are some key practices:

- Proper storage conditions: Store starch in a cool, dry place with adequate ventilation to prevent moisture absorption and mold growth.

- Pest control: Implement measures to control pests such as insects and rodents, which can contaminate the starch.

- FIFO inventory management: Use a first-in, first-out (FIFO) inventory system to prevent older starch from deteriorating before it is used.

- Regular inspections: Conduct regular inspections of stored starch to monitor quality and detect any signs of spoilage or contamination.

4. Discuss the importance of moisture control in dry starch operation and how it is achieved?

Moisture control is critical in dry starch operations as excessive moisture can lead to several issues, including starch degradation, lump formation, and reduced flowability. To achieve effective moisture control:

- Monitor moisture levels: Regularly monitor the moisture content of starch using moisture analyzers or other methods.

- Use drying equipment: Employ dryers or other equipment to remove excess moisture from the starch.

- Control environmental conditions: Maintain a low-humidity environment in storage and handling areas to prevent moisture absorption.

5. Explain the function of a starch blender and its role in ensuring product consistency?

A starch blender is a device used to mix different types or batches of starch to achieve a consistent product. Blending is crucial to ensure uniformity in properties such as viscosity, color, and particle size. The blender evenly distributes the starch particles, resulting in a homogeneous mixture that meets the desired specifications.

6. Describe the safety precautions and procedures to be followed when operating an automatic dry starch system?

Operating an automatic dry starch system requires adherence to strict safety precautions to prevent accidents and ensure the well-being of operators. These precautions include:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Follow lockout/tagout procedures when performing maintenance or repairs on the system.

- Be aware of potential hazards such as moving machinery, electrical equipment, and slippery surfaces.

- Receive proper training on the operation and safety protocols of the system.

7. Explain the role of automation in an automatic dry starch operation and its benefits?

Automation plays a vital role in modern dry starch operations, offering numerous benefits. It involves the use of programmable logic controllers (PLCs), sensors, and other devices to control and monitor the system. Automation helps:

- Improve efficiency by optimizing processes and reducing manual labor.

- Enhance safety by reducing human interaction with potential hazards.

- Increase consistency by automating tasks and minimizing human error.

- Monitor and control critical parameters such as temperature, pressure, and flow rates.

8. Discuss the importance of preventive maintenance in an automatic dry starch operation?

Preventive maintenance is essential to ensure the smooth and efficient operation of an automatic dry starch system. It involves regular inspections, servicing, and repairs to identify and address potential issues before they cause significant downtime or breakdowns. A well-maintained system helps:

- Extend equipment life by preventing premature wear and tear.

- Reduce the risk of unplanned outages and costly repairs.

- Maintain optimal performance and efficiency of the system.

- Ensure compliance with safety regulations and industry standards.

9. How do you troubleshoot common problems that may occur in an automatic dry starch system?

Troubleshooting common problems in an automatic dry starch system requires a systematic approach. Some common issues and their potential solutions include:

- Blockage in the conveying system: Check for any obstructions or blockages in the pipes or ducts and clear them accordingly.

- Insufficient airflow: Verify that the blower is operating correctly and providing adequate airflow for material transportation.

- Temperature deviations: Monitor temperature sensors and ensure they are functioning properly. Adjust the heating or cooling system as needed.

- Inconsistent starch quality: Check the starch source and ensure it meets the required specifications. Adjust the blending or drying processes to achieve the desired quality.

10. Describe your experience in working with different types of starch and how you have adapted to their unique properties?

Throughout my career, I have had the opportunity to work with a variety of starch types, each possessing unique properties and requiring specific handling techniques. For example, with high-amylose starch, I focused on controlling gelatinization temperature and shear forces to achieve the desired viscosity. In the case of waxy starch, I adjusted the drying conditions to prevent excessive retrogradation and maintain its soft texture. By understanding the distinct characteristics of different starches, I have successfully adapted my approach to optimize their performance in various applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Dry Starch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Dry Starch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Automatic Dry Starch Operator is responsible for operating and maintaining the automatic dry starch system in a manufacturing plant. This system is used to create starch products for various industries, such as paper, food, and textiles.

1. Operate and Maintain Starch System Equipment

Monitor and control the operation of the automatic dry starch system, including the starch feeders, mixers, dryers, and conveyors.

- Adjust machinery speed, temperature, and other variables to maintain optimal production conditions.

- Conduct routine maintenance and repairs to ensure equipment is functioning properly.

2. Test Starch Products

Collect and test starch products to ensure they meet specifications and quality standards.

- Determine moisture content, particle size, and other properties of the starch.

- Adjust production parameters and equipment settings based on test results.

3. Monitor and Control Environmental Conditions

Monitor and control the environmental conditions in the production area, including temperature, humidity, and dust levels.

- Operate ventilation systems and adjust environmental controls to maintain a safe and efficient work environment.

- Ensure compliance with environmental regulations.

4. Follow Safety Procedures

Follow established safety procedures and protocols to ensure the safety of themselves and others.

- Wear appropriate personal protective equipment (PPE) and maintain a clean and organized work area.

- Report any accidents, injuries, or unsafe conditions to supervisors and follow up on corrective actions.

Interview Tips

Preparing for an interview for an Automatic Dry Starch Operator position requires a combination of technical knowledge and demonstration of essential skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company you are applying to and the specific Automatic Dry Starch Operator position. This will give you a good understanding of the company’s culture, values, and the responsibilities and requirements of the role.

2. Prepare for Technical Questions

Review the key job responsibilities and prepare for questions that may test your technical knowledge and understanding of the starch production process. Be prepared to discuss your experience with operating and maintaining similar equipment, as well as your understanding of starch properties and testing methods.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the requirements of the job. Provide specific examples of your accomplishments and how they demonstrate your abilities in operating and monitoring starch production equipment, troubleshooting and solving problems, and maintaining a safe work environment.

4. Be Enthusiastic and Confident

During the interview, convey your enthusiasm for the role and the starch industry. Express your confidence in your abilities and highlight your willingness to learn and grow within the organization.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This demonstrates your interest in the position and the company, and gives you an opportunity to clarify any aspects of the role or the organization that you may need further information on.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Dry Starch Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!