Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Engraver interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Engraver so you can tailor your answers to impress potential employers.

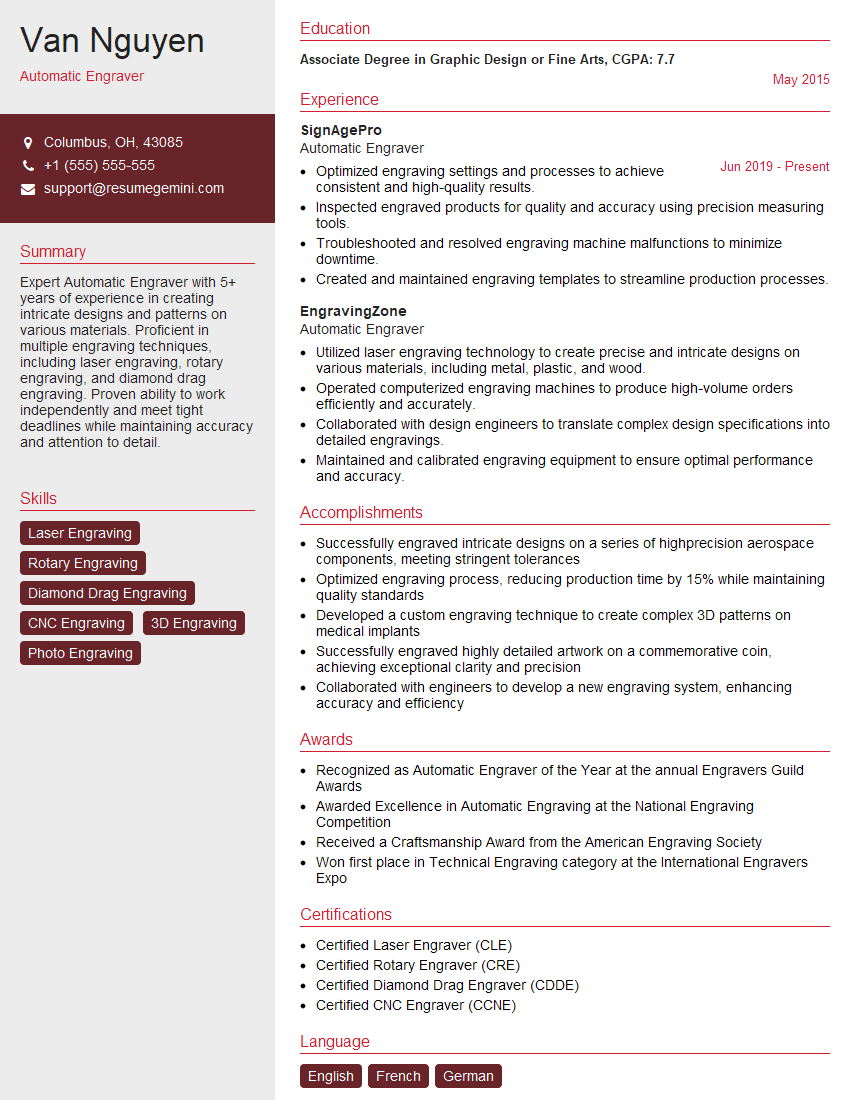

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Engraver

1. What are the different types of engraving machines and what are their capabilities?

- Mechanical engraving machines: These machines use a mechanical cutter to carve designs into the surface of the material. They are typically used for engraving metals, plastics, and wood.

- Laser engraving machines: These machines use a laser beam to engrave designs into the surface of the material. They are typically used for engraving metals, plastics, wood, and glass.

- CNC engraving machines: These machines are computer-controlled and can engrave complex designs into the surface of the material. They are typically used for engraving metals, plastics, wood, and glass.

2. What are the different types of engraving materials and what are their properties?

- Metals: Metals are the most common material used for engraving. They are durable and can be engraved with a variety of techniques.

- Plastics: Plastics are a versatile material that can be engraved with a variety of techniques. They are lightweight and inexpensive.

- Wood: Wood is a natural material that can be engraved with a variety of techniques. It is relatively inexpensive and easy to work with.

- Glass: Glass is a fragile material that must be engraved with care. It can be engraved with a variety of techniques, but laser engraving is the most common.

3. What are the different safety precautions that must be taken when operating an engraving machine?

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Follow the manufacturer’s instructions for operating the machine.

- Never leave the machine unattended while it is operating.

- Keep the work area clean and free of debris.

- Dispose of waste materials properly.

4. What are the common problems that can occur when operating an engraving machine and how can they be solved?

- The machine is not engraving properly: This could be caused by a dull cutter, a loose belt, or a dirty machine. To solve this problem, check the cutter, tighten the belt, and clean the machine.

- The engraving is not deep enough: This could be caused by a dull cutter, a low power setting, or a slow feed rate. To solve this problem, sharpen the cutter, increase the power setting, or increase the feed rate.

- The engraving is too deep: This could be caused by a sharp cutter, a high power setting, or a fast feed rate. To solve this problem, dull the cutter, decrease the power setting, or decrease the feed rate.

- The engraving is not accurate: This could be caused by a loose belt, a worn cutter, or a misaligned machine. To solve this problem, tighten the belt, replace the cutter, and align the machine.

5. What are the different types of engraving software and what are their features?

- CAD (computer-aided design) software: CAD software is used to create 2D and 3D models of objects. It can be used to create designs for engraving, as well as for other purposes such as engineering and architecture.

- CAM (computer-aided manufacturing) software: CAM software is used to convert CAD models into instructions that can be used by an engraving machine. It can be used to create toolpaths, which are the paths that the engraving machine will follow to create the design.

- Raster engraving software: Raster engraving software is used to create images that can be engraved onto a surface. It can be used to create photos, logos, and other types of images.

6. What are the different types of engraving applications and what are their benefits?

- Industrial engraving: Industrial engraving is used to create parts and components for a variety of industries, such as automotive, aerospace, and medical.

- Commercial engraving: Commercial engraving is used to create signs, labels, and other products for businesses.

- Personal engraving: Personal engraving is used to create personalized items, such as jewelry, gifts, and trophies.

7. What are the career prospects for an automatic engraver?

- Automatic engravers can work in a variety of industries, including manufacturing, retail, and jewelry.

- The job outlook for automatic engravers is expected to be good in the coming years, as the demand for engraved products continues to grow.

- Automatic engravers can advance their careers by becoming supervisors, managers, or owners of their own engraving businesses.

8. What are the skills and qualities that are required to be a successful automatic engraver?

- Technical skills: Automatic engravers need to have a good understanding of engraving machines and software.

- Artistic skills: Automatic engravers need to have a good eye for detail and be able to create designs that are both aesthetically pleasing and functional.

- Customer service skills: Automatic engravers need to be able to work with customers to understand their needs and provide them with the best possible service.

- Safety skills: Automatic engravers need to be able to follow safety procedures and work in a safe environment.

9. What is your experience with operating an automatic engraving machine?

I have been operating an automatic engraving machine for the past five years. I am proficient in using a variety of engraving software and techniques. I have experience engraving a wide range of materials, including metals, plastics, wood, and glass.

10. What are your strengths and weaknesses as an automatic engraver?

- Strengths: I am a highly skilled and experienced automatic engraver.

- Weaknesses: I am always looking for ways to improve my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Automatic Engraver, you’ll play a crucial role in the setup, operation, and maintenance of automated engraving equipment. Your primary responsibilities will include:

1. Equipment Setup and Operation

Setting up and calibrating automated engraving machines to ensure precise and accurate engravings.

- Loading and unloading workpieces into the engraving machines.

- Selecting and installing appropriate engraving tools and materials.

- Monitoring the engraving process to ensure optimal results.

2. Workpiece Preparation

Preparing workpieces for engraving, including cleaning, degreasing, and masking sensitive areas.

- Verifying workpiece dimensions and designs before engraving.

- Inspecting workpieces to ensure they are free of defects and meet quality standards.

3. Job Management

Managing engraving jobs, including prioritizing tasks, setting production schedules, and coordinating with other departments.

- Tracking job progress and reporting on completion times.

- Maintaining records of completed engravings.

4. Troubleshooting and Maintenance

Troubleshooting engraving machines and resolving technical issues to minimize downtime.

- Performing routine maintenance and cleaning of engraving equipment.

- Identifying and replacing worn or damaged components.

- Collaborating with maintenance personnel for major repairs.

Interview Preparation Tips

To ace your interview for an Automatic Engraver position, it’s essential to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific engraving industry. Learn about their products, services, and values. This will demonstrate your interest in the company and help you align your answers with their needs.

2. Practice Your Answers

Consider common interview questions related to your skills, experience, and why you’re interested in the role. Practice answering these questions concisely and enthusiastically. Use examples from your past experience or projects to highlight your abilities.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining automated engraving machines. Discuss your knowledge of engraving techniques, substrates, and tool selection. Quantify your accomplishments with specific metrics, such as the number of workpieces engraved per hour or the reduction in downtime achieved.

4. Showcase Your Attention to Detail

Automatic Engravers must have an excellent eye for detail and precision. Highlight your ability to produce high-quality engravings that meet exact specifications. Mention any quality control measures or certifications you have obtained that demonstrate your commitment to accuracy.

5. Be Prepared to Discuss Safety

Engraving machines are powerful tools, so safety is paramount. Be prepared to answer questions about your safety knowledge and practices. Discuss any safety training or certifications you have received and how you prioritize safety in your work.

Next Step:

Now that you’re armed with the knowledge of Automatic Engraver interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Engraver positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini