Are you gearing up for a career in Automatic Label Cutting and Folding Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Label Cutting and Folding Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

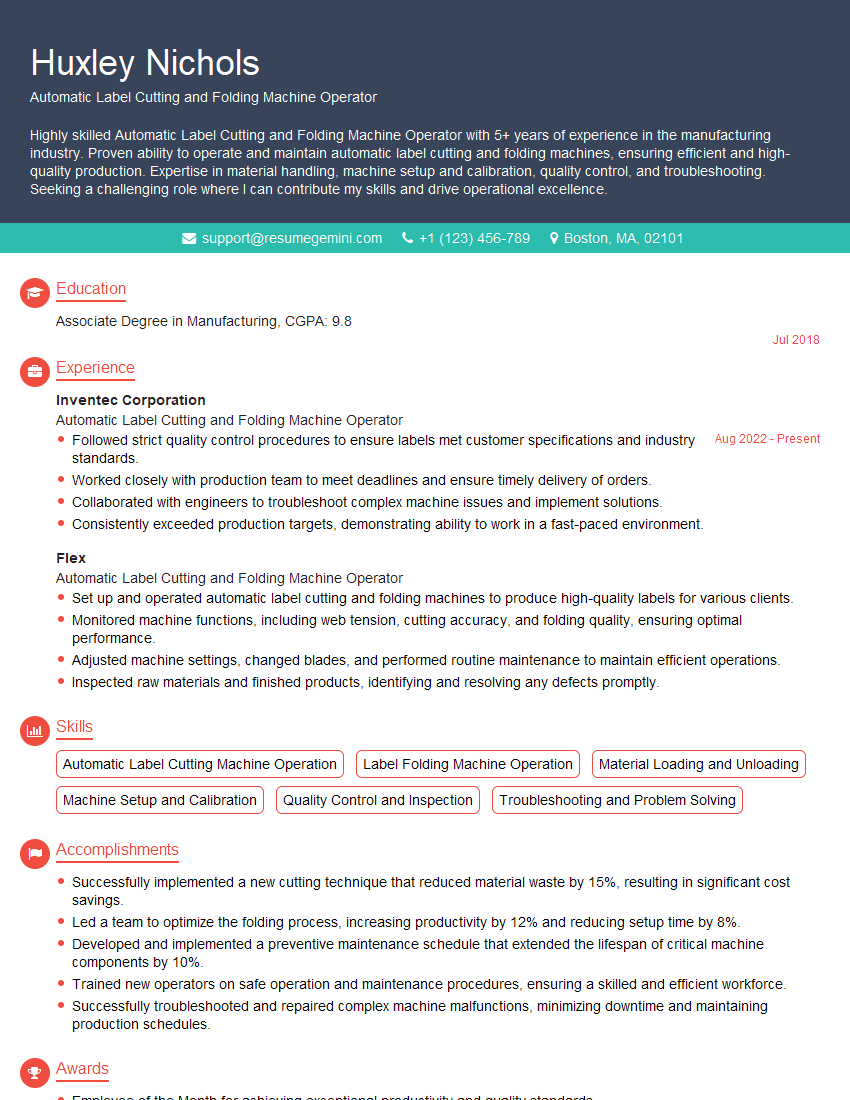

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Label Cutting and Folding Machine Operator

1. Explain the process of setting up and operating an automatic label cutting and folding machine?

The process of setting up and operating an automatic label cutting and folding machine involves several key steps:

- Loading the material: The first step is to load the roll of label material onto the machine. This involves threading the material through the machine’s guides and ensuring that it is properly aligned.

- Setting the machine parameters: Once the material is loaded, the machine parameters need to be set. This includes specifying the label size, cutting speed, and folding pattern.

- Starting the machine: Once the parameters are set, the machine can be started. The machine will automatically feed the material through the cutting and folding process.

- Monitoring the machine: While the machine is running, it is important to monitor its operation. This includes checking for any errors or problems that may occur.

- Unloading the finished labels: Once the labels have been cut and folded, they can be unloaded from the machine. This involves removing the finished labels from the machine’s output tray.

2. What are the different types of materials that can be used with an automatic label cutting and folding machine?

Types of materials:

- Paper: Paper is the most common material used with automatic label cutting and folding machines. It is available in a variety of grades and thicknesses, and can be used for a wide range of applications.

- Film: Film is another common material used with automatic label cutting and folding machines. It is more durable than paper and is often used for labels that will be exposed to harsh conditions.

- Foil: Foil is a metallized material that is often used for labels that require a high degree of durability and resistance to wear and tear.

3. What are the different types of cuts that can be made with an automatic label cutting and folding machine?

There are a variety of different cuts that can be made with an automatic label cutting and folding machine, including:

- Straight cuts: Straight cuts are the most common type of cut made with an automatic label cutting and folding machine. They are used to create labels with simple, straight edges.

- Die cuts: Die cuts are used to create labels with complex shapes. They are made using a die that is shaped to the desired label shape.

- Kiss cuts: Kiss cuts are used to create labels that are partially cut through. This allows the label to be easily removed from the backing material.

4. What are the different types of folds that can be made with an automatic label cutting and folding machine?

There are a variety of different folds that can be made with an automatic label cutting and folding machine, including:

- Single folds: Single folds are the most common type of fold made with an automatic label cutting and folding machine. They are used to create labels that have a single fold in the middle.

- Double folds: Double folds are used to create labels that have two folds, one in the middle and one on each side.

- Gate folds: Gate folds are used to create labels that have a single fold in the middle and two folds on the outside.

5. What are troubleshooting tips for automatic label cutting and folding machines?

Troubleshooting tips for automatic label cutting and folding machines include:

- Check the material: Make sure that the material is properly loaded and aligned in the machine.

- Check the machine parameters: Make sure that the machine parameters are set correctly for the material being used.

- Check the cutting blade: Make sure that the cutting blade is sharp and free of debris.

- Check the folding mechanism: Make sure that the folding mechanism is working properly and that the labels are being folded correctly.

- Check for errors: If the machine is displaying an error message, refer to the machine’s manual for troubleshooting instructions.

6. How can you ensure the quality of labels produced by an automatic label cutting and folding machine?

To ensure the quality of labels produced by an automatic label cutting and folding machine, you can follow these steps:

- Use high-quality materials: The quality of the labels will be determined by the quality of the materials used. Use high-quality materials that are suitable for the intended application.

- Set the machine parameters correctly: The machine parameters will affect the quality of the cut and fold. Make sure that the parameters are set correctly for the material being used.

- Maintain the machine: Regular maintenance will help to ensure that the machine is operating properly and producing high-quality labels.

- Inspect the labels: After the labels have been produced, inspect them for any defects. This will help to ensure that only high-quality labels are used.

7. What are the safety precautions that should be taken when operating an automatic label cutting and folding machine?

When operating an automatic label cutting and folding machine, it is important to take the following safety precautions:

- Wear appropriate safety gear: Always wear appropriate safety gear, such as safety glasses and gloves, when operating the machine.

- Keep hands away from moving parts: Keep your hands away from all moving parts of the machine, including the cutting blade and folding mechanism.

- Do not operate the machine if it is damaged: If the machine is damaged, do not operate it until it has been repaired.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for operating the machine.

8. What are the common maintenance tasks that should be performed on an automatic label cutting and folding machine?

Common maintenance tasks that should be performed on an automatic label cutting and folding machine include:

- Cleaning the machine: The machine should be cleaned regularly to remove any dust or debris. This will help to prevent the machine from malfunctioning.

- Oiling the machine: The machine should be oiled regularly to keep the moving parts lubricated. This will help to prevent the machine from wearing out prematurely.

- Checking the cutting blade: The cutting blade should be checked regularly for sharpness. If the blade is dull, it should be replaced.

- Checking the folding mechanism: The folding mechanism should be checked regularly for wear and tear. If the mechanism is worn, it should be repaired or replaced.

9. What is a die-cutting machine, and how does it work?

A die-cutting machine is a machine that cuts shapes out of materials using a die. A die is a metal blade that is shaped to the desired cut shape. The material is placed between the die and a cutting surface, and the die is then pressed down to cut the shape.

Die-cutting machines are used to cut a wide variety of materials, including paper, cardboard, plastic, and metal. They are used to create a variety of products, including labels, packaging, and signs.

10. What are the different types of die-cutting machines?

There are two main types of die-cutting machines: flatbed die-cutting machines and rotary die-cutting machines.

Flatbed die-cutting machines are used to cut shapes out of flat materials. The material is placed on a flatbed, and the die is then pressed down to cut the shape.

Rotary die-cutting machines are used to cut shapes out of continuous materials, such as paper or film. The material is fed through the machine, and the die is rotated to cut the shape.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Label Cutting and Folding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Label Cutting and Folding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Automatic Label Cutting and Folding Machine Operator is accountable for efficiently operating and maintaining automated machinery to cut and fold labels, ensuring high-quality production and adhering to production targets.

1. Machine Operation

Setting up, calibrating, and operating automatic label cutting and folding machines according to specified requirements.

- Feeding raw materials into the machine.

- Monitoring the cutting and folding processes, making adjustments as needed.

2. Quality Control

Inspecting labels for defects, dimensions, and adherence to specifications.

- Identifying and resolving production issues promptly.

- Maintaining accurate records of production and quality.

3. Maintenance

Conducting routine maintenance and cleaning of the machine.

- Identifying and reporting any mechanical or electrical issues.

- Participating in preventive maintenance programs.

4. Production Planning

Collaborating with the production team to plan and schedule production runs.

- Estimating production times and materials required.

- Ensuring timely delivery of finished products.

Interview Tips

Preparing thoroughly for the interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s profile, products, and services. Review the job description thoroughly, identifying the key responsibilities and qualifications.

- This knowledge will help you answer interview questions confidently.

- Example: “I understand that ABC Company is a leading provider of labeling solutions. I believe my experience in operating automatic label cutting and folding machines aligns well with the skills required for this role.”

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating similar machinery and your understanding of cutting and folding processes. Showcase your abilities in quality control, troubleshooting, and preventive maintenance.

- Quantify your achievements using specific metrics whenever possible.

- Example: “At my previous role, I consistently achieved a 99.5% accuracy rate in label cutting and folding, reducing production waste by 15%.”

3. Practice Common Interview Questions

Anticipate typical interview questions and prepare your responses in advance. Consider questions related to your experience, skills, and motivation. You may also encounter situational questions that assess your problem-solving abilities and work style.

- Practice using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Example: “In a previous situation where a machine malfunctioned, I quickly identified the issue and implemented a temporary solution, preventing a prolonged production downtime.”

4. Display Enthusiasm and Interest

Demonstrate your enthusiasm for the role and the company. Express how your skills and experience can contribute to the organization’s success. Ask thoughtful questions about the company, the position, and the team you would be working with.

- Your enthusiasm can leave a lasting impression and show the interviewer your genuine interest in the opportunity.

- Example: “I am particularly excited about the opportunity to contribute my expertise in label production to ABC Company. I believe that my skills can enhance your team’s capabilities and drive productivity.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Label Cutting and Folding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!