Are you gearing up for an interview for a Automatic Metal Spraying Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Automatic Metal Spraying Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

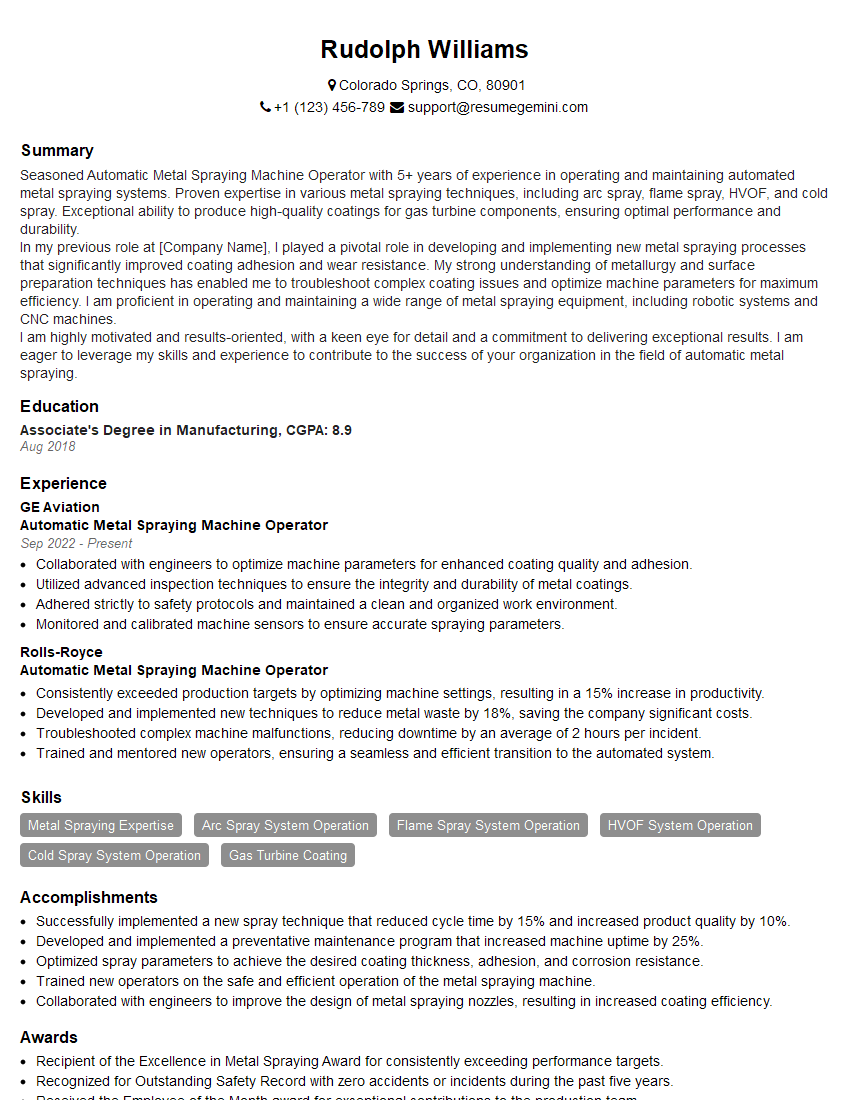

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Metal Spraying Machine Operator

1. Explain the process of thermal spraying?

Thermal spraying is a coating process in which a material is melted and sprayed onto a substrate. The melting is typically done using an oxy-fuel torch, plasma arc, or electric arc. The molten material is then sprayed onto the substrate using a spray gun. The spray gun can be hand-held or automated.

2. What are the different types of thermal spraying processes?

Flame spraying

- Uses a fuel gas (such as propane or acetylene) and oxygen to create a flame.

- The material to be sprayed is introduced into the flame and melted.

- The molten material is then sprayed onto the substrate using a spray gun.

Plasma spraying

- Uses a plasma arc to melt the material to be sprayed.

- The plasma arc is created by passing an electrical current through a gas (such as argon or nitrogen).

- The molten material is then sprayed onto the substrate using a spray gun.

Electric arc spraying

- Uses an electric arc to melt the material to be sprayed.

- The electric arc is created between two electrodes.

- The molten material is then sprayed onto the substrate using a spray gun.

3. What are the advantages of thermal spraying?

- Can be used to apply a wide variety of materials, including metals, ceramics, and polymers.

- Can be used to create coatings with a wide range of properties, including corrosion resistance, wear resistance, and thermal insulation.

- Can be used to coat complex shapes and geometries.

4. What are the disadvantages of thermal spraying?

- Can be a relatively expensive process.

- Can be difficult to control the thickness and uniformity of the coating.

- Can be difficult to achieve a high bond strength between the coating and the substrate.

5. What are the applications of thermal spraying?

- Aerospace

- Automotive

- Chemical processing

- Construction

- Electronics

- Food processing

- Glass

- Medical

- Oil and gas

- Paper

- Plastics

- Power generation

- Rail

- Shipbuilding

- Textiles

6. What are the safety precautions that must be taken when operating a thermal spraying machine?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and eye protection.

- Make sure the work area is well-ventilated.

- Keep the spray gun clean and free of debris.

- Never point the spray gun at anyone.

- Follow all manufacturer’s instructions for the safe operation of the machine.

7. What are the maintenance procedures that must be performed on a thermal spraying machine?

- Clean the spray gun and nozzle regularly.

- Inspect the hoses and fittings for leaks.

- Lubricate the moving parts of the machine.

- Check the electrical connections.

- Follow all manufacturer’s instructions for the maintenance of the machine.

8. What are the troubleshooting procedures for a thermal spraying machine?

- If the machine is not spraying properly, check the spray gun, nozzle, and hoses for blockages.

- If the coating is not adhering to the substrate, check the surface preparation and the coating thickness.

- If the machine is overheating, check the cooling system.

- If the machine is making strange noises, check the bearings and gears.

- Follow all manufacturer’s instructions for the troubleshooting of the machine.

9. What are the different types of metallizing processes?

- Arc spraying

- Flame spraying

- Plasma spraying

- High-velocity oxy-fuel (HVOF) spraying

- Cold spraying

10. What are the applications of metallizing?

- Corrosion protection

- Wear resistance

- Electrical conductivity

- Thermal conductivity

- декоративные

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Metal Spraying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Metal Spraying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Metal Spraying Machine Operators are responsible for operating and maintaining a range of automatic metal spraying machines. These machines are used to apply a protective coating of metal to a variety of surfaces, such as automotive parts, aircraft components, and medical devices.

1. Operating the Machine

Operators must be able to set up and operate the machine according to the manufacturer’s instructions. They must also be able to monitor the machine’s operation and make adjustments as needed.

- Loading and unloading the machine

- Setting up the machine’s parameters

- Monitoring the machine’s operation

- Making adjustments to the machine’s settings

2. Maintaining the Machine

Operators are also responsible for maintaining the machine. This includes cleaning and lubricating the machine, as well as performing minor repairs.

- Cleaning and lubricating the machine

- Performing minor repairs

- Inspecting the machine for damage

- Reporting any problems to the supervisor

3. Quality Control

Operators are also responsible for ensuring that the quality of the metal coating meets the customer’s specifications. This includes inspecting the coating for defects, such as cracks, pores, and inclusions.

- Inspecting the metal coating for defects

- Rejecting any parts that do not meet the customer’s specifications

- Maintaining records of the quality of the metal coating

4. Safety

Operators must be aware of the safety hazards associated with operating an automatic metal spraying machine. These hazards include exposure to fumes, dust, and molten metal. Operators must also be able to use personal protective equipment, such as respirators and gloves.

- Wearing personal protective equipment

- Following safety procedures

- Reporting any safety hazards to the supervisor

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you prepare for your Automatic Metal Spraying Machine Operator interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website

- Follow the company on social media

- Read reviews of the company on Glassdoor

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with automated metal spraying machines?

- How do you handle working in a fast-paced environment?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience operating automatic metal spraying machines. Be prepared to discuss your experience in detail, including your responsibilities, accomplishments, and any challenges you have faced.

- Describe your experience operating automatic metal spraying machines.

- Discuss your responsibilities, accomplishments, and any challenges you have faced.

- Be prepared to answer questions about your experience in detail.

4. Be enthusiastic and professional

The interviewer will be able to tell if you are enthusiastic about the position and the company. Be sure to show your enthusiasm during the interview. However, it is also important to be professional and respectful. Dress appropriately and arrive on time for your interview.

- Be enthusiastic about the position and the company.

- Dress appropriately and arrive on time for your interview.

- Be professional and respectful during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Metal Spraying Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!