Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Pad-Making Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Pad-Making Machine Operator so you can tailor your answers to impress potential employers.

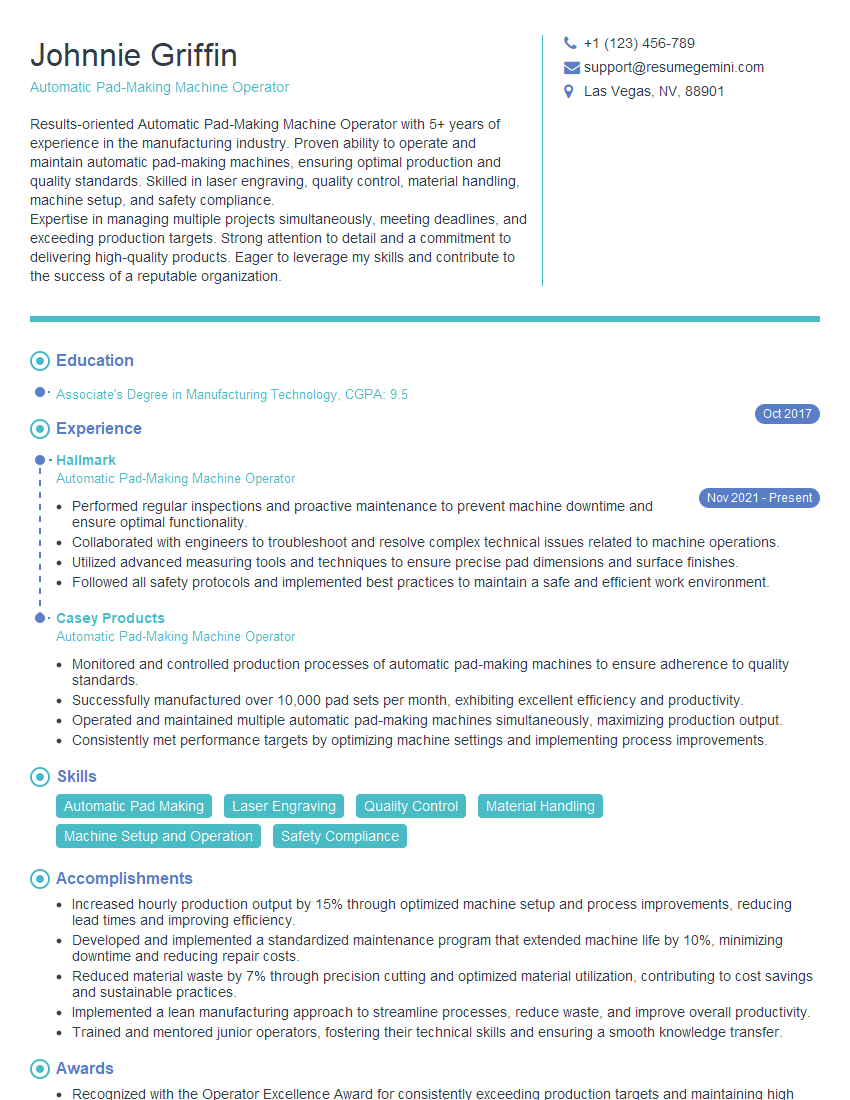

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Pad-Making Machine Operator

1. What are the key responsibilities of an Automatic Pad-Making Machine Operator?

- Operate and maintain an automatic pad-making machine to produce high-quality pads.

- Monitor the machine’s performance, including speed, temperature, and pressure, and make necessary adjustments.

- Inspect the finished pads for defects and ensure that they meet the required specifications.

- Perform routine maintenance and cleaning of the machine.

- Collaborate with other team members to ensure the smooth operation of the production line.

2. Describe the process of setting up the Automatic Pad-Making Machine.

Machine Preparation

- Check the machine for any damage or malfunctions.

- Clean the machine and remove any debris.

- Lubricate the moving parts.

Material Loading

- Load the raw materials, such as paper and glue, into the designated containers.

- Set the material specifications, such as paper thickness and glue viscosity, into the machine’s control panel.

Machine Configuration

- Select the desired pad size and shape.

- Set the machine’s speed, temperature, and pressure settings.

- Start the machine and monitor its performance.

3. How do you troubleshoot common problems that may occur during the operation of an Automatic Pad-Making Machine?

- Paper jams: Check the paper feed mechanism for any obstructions or damage. Adjust the paper tension settings.

- Glue leakage: Inspect the glue applicators and hoses for leaks or blockages. Tighten connections and replace faulty components.

- Poor adhesion: Ensure the correct glue type and viscosity are being used. Check the machine’s temperature and pressure settings.

- Uneven pad thickness: Calibrate the machine’s pressure sensors and adjust the roller settings.

- Machine overheating: Check the machine’s cooling system for any malfunctions or blockages. Clean the air filters and ensure proper ventilation.

4. What safety precautions should be taken when operating an Automatic Pad-Making Machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a hairnet.

- Keep your hands away from moving parts.

- Be aware of potential hazards, such as hot surfaces and sharp edges.

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

- Report any accidents or incidents to the supervisor immediately.

5. How do you ensure the quality of the finished pads?

- Inspect the pads visually for any defects, such as uneven thickness, poor adhesion, or surface imperfections.

- Use measuring tools to verify the pads meet the required specifications for size and shape.

- Perform random sampling and testing to ensure the pads meet performance standards, such as durability and absorption capacity.

- Maintain accurate records of quality checks and any corrective actions taken.

6. What is your experience with preventive maintenance and repair of Automatic Pad-Making Machines?

- Conduct regular inspections and cleaning to prevent equipment breakdowns.

- Identify potential issues through performance monitoring and predictive maintenance techniques.

- Perform scheduled maintenance tasks, such as lubrication, belt replacement, and filter cleaning.

- Troubleshoot and repair machine malfunctions, using diagnostic tools and technical manuals.

- Maintain detailed maintenance records and report any issues to the supervisor.

7. How do you stay up-to-date with the latest advancements in Automatic Pad-Making Machine technology?

- Attend industry conferences and trade shows.

- Read technical journals and online articles.

- Engage in discussions with other professionals in the field.

- Participate in training programs offered by equipment manufacturers.

8. How do you prioritize your tasks and manage your time effectively when working as an Automatic Pad-Making Machine Operator?

- Plan ahead and anticipate potential issues.

- Set priorities based on production deadlines and equipment status.

- Delegate tasks to other team members when necessary.

- Use time management tools, such as checklists and schedules.

- Stay organized and maintain a clean work area.

9. How do you handle working in a fast-paced and demanding production environment?

- Remain calm under pressure and maintain a positive attitude.

- Communicate effectively with other team members.

- Be flexible and adaptable to changing production demands.

- Take breaks when needed to prevent fatigue and errors.

- Seek support from supervisors and colleagues when necessary.

10. Why are you interested in this position as an Automatic Pad-Making Machine Operator at our company?

- I am eager to contribute my skills and experience to your team.

- I am impressed by your company’s commitment to quality and innovation.

- I am confident that I can make a valuable contribution to your production process.

- I am excited about the opportunity to learn and grow in a dynamic and challenging environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Pad-Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Pad-Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Pad-Making Machine Operators oversee the production of printing pads using automated machinery. Their primary duties include:

1. Machine Operation

Operate and monitor automatic pad-making machines to produce printing pads as per specifications.

- Set up and calibrate machines by adjusting parameters such as pressure, temperature, and speed.

- Monitor the printing process, making adjustments as needed to ensure the quality of the pads.

2. Material Handling

Handle and store raw materials and finished pads, ensuring proper inventory management.

- Inspect raw materials to verify their quality and conform to specifications.

- Load raw materials into the machine and unload finished pads for further processing.

3. Quality Control

Inspect finished pads for defects, ensuring they meet quality standards.

- Follow inspection protocols and use measuring instruments to verify the dimensions and properties of the pads.

- Record quality control data and report any discrepancies to the supervisor.

4. Equipment Maintenance

Perform basic maintenance and troubleshooting of the pad-making machine.

- Clean and lubricate machine components regularly.

- Identify and resolve minor malfunctions, replacing parts if necessary.

Interview Tips

To prepare for an interview for the position of Automatic Pad-Making Machine Operator, consider the following tips:

1. Research the Company

Review the company’s website, social media pages, and industry news to understand its products, services, culture, and recent developments.

- This demonstrates your interest in the company and your knowledge of the industry.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience with automatic pad-making machines, quality control procedures, and troubleshooting techniques.

- Consider using the STAR method (Situation, Task, Action, Result) when answering questions to provide specific examples of your skills and accomplishments.

3. Highlight Your Technical Skills

Emphasize your familiarity with different types of pad-making machines, their components, and their operation.

- Discuss your knowledge of quality control standards and inspection methods used in the manufacturing process.

4. Showcase Your Problem-Solving Abilities

Share examples where you identified and resolved machine malfunctions or production issues.

- Highlight your analytical thinking, troubleshooting skills, and ability to work independently to find solutions.

5. Display Your Safety Awareness

Emphasize your understanding of safety protocols and your adherence to industry best practices.

- Discuss your experience with lockout/tagout procedures, proper use of personal protective equipment, and emergency response plans.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automatic Pad-Making Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.