Are you gearing up for an interview for a Automatic Pattern Edger position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Automatic Pattern Edger and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

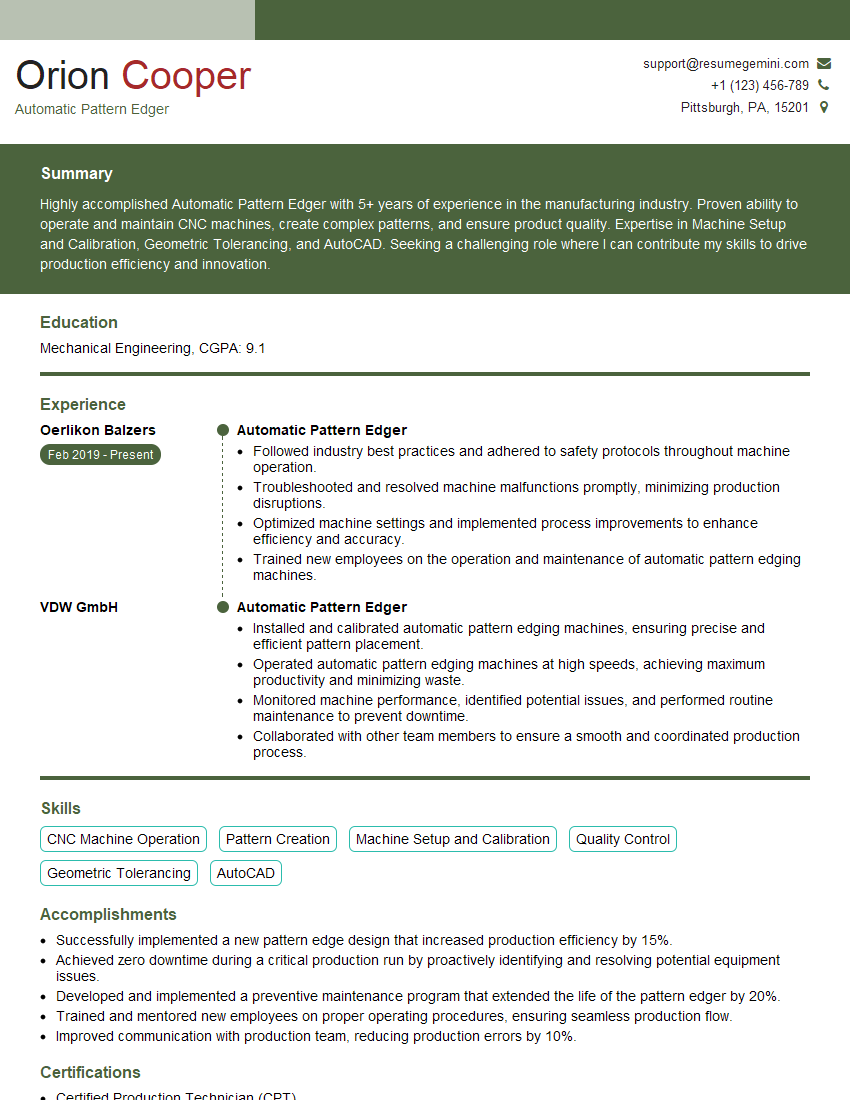

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Pattern Edger

1. What is the role of an Automatic Pattern Edger?

As an Automatic Pattern Edger, my primary responsibility is to operate and maintain the Pattern Edging Machine. This involves setting up the machine according to design specifications, loading and aligning materials, and ensuring the machine operates smoothly and efficiently to produce high-quality pattern edges on various materials.

2. Describe the key features and functions of an Automatic Pattern Edging Machine.

- Automatic Operation: The machine is programmed to follow specific patterns and edge materials automatically, reducing manual labor.

- Precision Cutting: It employs precision cutting tools to create clean, accurate edges on various materials.

- Material Compatibility: The machine can handle a wide range of materials, including wood, plastic, metal, and composites.

- Edge Profile Customization: It allows for customization of edge profiles, enabling the creation of intricate and complex designs.

- Safety Features: The machine incorporates safety features such as guards and emergency stop buttons to ensure operator safety.

3. What are the common materials used in Automatic Pattern Edging?

- Wood (hardwoods, softwoods, plywood)

- Plastic (acrylic, PVC, ABS)

- Metal (aluminum, steel)

- Composites (fiberglass, carbon fiber)

4. What are the key factors to consider when choosing the right edge profile for a particular application?

- Material Type: Different materials require specific edge profiles to optimize their strength and durability.

- Functional Requirements: The edge profile should match the intended use of the material, whether it’s for decoration, structural support, or joining.

- Aesthetic Considerations: The edge profile should complement the overall design and appearance of the product.

- Machine Compatibility: The machine should be capable of producing the desired edge profile accurately.

5. What steps would you take to troubleshoot a common jam or error on an Automatic Pattern Edging Machine?

- Identify the Error Code: Check the machine’s display or manual for error codes to identify the issue.

- Inspect Material Alignment: Ensure that the material is properly loaded and aligned within the machine.

- Clean the Cutting Tools: Remove any debris or buildup from the cutting tools that may cause jamming.

- Check Sensor Operation: Verify that the sensors are functioning correctly and detecting materials properly.

- Reset the Machine: If necessary, reset the machine following the manufacturer’s instructions.

6. How do you maintain and calibrate an Automatic Pattern Edging Machine to ensure optimal performance?

- Regular Cleaning: Keep the machine clean and free of dust and debris to prevent malfunctions.

- Tool Maintenance: Sharpen or replace cutting tools regularly to maintain precision and avoid tearing.

- Sensor Calibration: Calibrate the sensors to ensure accurate material detection and alignment.

- Software Updates: Install software updates provided by the manufacturer to enhance machine performance and functionality.

- Lubrication: Lubricate moving parts regularly to minimize friction and wear.

7. Describe the safety precautions you would observe when operating an Automatic Pattern Edging Machine.

- Wear Protective Gear: Always wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Clear the Work Area: Ensure that the work area is free of obstacles and potential hazards.

- Follow Machine Instructions: Adhere to the manufacturer’s operating instructions for safe machine operation.

- Avoid Loose Clothing: Wear clothing that fits snugly to prevent entanglement in moving parts.

- Stay Alert: Pay attention to the machine’s operation and be aware of potential hazards.

8. What types of training or certification are required for an Automatic Pattern Edger?

- Machine-Specific Training: Receive training from the manufacturer or a certified technician on the specific model of Automatic Pattern Edging Machine you will be operating.

- Industry Standards: Familiarize yourself with industry standards and best practices for pattern edging.

- Safety Certifications: Obtain safety certifications, such as OSHA or ANSI, to demonstrate your understanding of workplace safety regulations.

9. How would you contribute to a team environment as an Automatic Pattern Edger?

- Effective Communication: Communicate clearly and effectively with team members to ensure smooth coordination and timely project completion.

- Collaboration: Work collaboratively with other team members, sharing knowledge and supporting each other’s tasks.

- Problem-Solving: Participate in problem-solving discussions, offering suggestions and contributing to finding solutions.

- Quality Assurance: Maintain high standards of quality in your work and strive for continuous improvement.

10. Why are you interested in this role as an Automatic Pattern Edger?

I am passionate about precision manufacturing and have always been fascinated by the process of pattern edging. I am eager to contribute my skills and knowledge to your team and help produce high-quality products. Furthermore, I am confident that my ability to learn quickly, troubleshoot effectively, and work collaboratively make me an ideal candidate for this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Pattern Edger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Pattern Edger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Pattern Edger is responsible for operating a machine that cuts and shapes fabric using computerized patterns. The primary duties include:

1. Pattern Setup and Operation

Setting up the machine with the appropriate fabric and patterns.

- Loading and securing fabric rolls onto the machine.

- Selecting and uploading digital patterns into the machine’s computer system.

- Calibrating and adjusting the machine for optimal cutting accuracy.

2. Machine Operation and Monitoring

Operating the machine safely and efficiently to cut fabric.

- Starting and stopping the machine as needed.

- Monitoring the machine’s operation and identifying any potential issues.

- Ensuring that the machine is cutting fabric according to the specified patterns.

3. Fabric Handling and Quality Control

Handling fabric before and after cutting, ensuring its quality.

- Inspecting fabric for defects before cutting.

- Removing cut fabric pieces from the machine.

- Inspecting cut fabric pieces for accuracy and quality.

4. Machine Maintenance and Troubleshooting

Performing basic maintenance and troubleshooting to keep the machine running smoothly.

- Cleaning and lubricating the machine as per manufacturer’s guidelines.

- Troubleshooting minor issues and performing minor repairs.

- Reporting any major issues or repairs to the supervisor.

Interview Tips

To ace the interview for the Automatic Pattern Edger position, candidates should focus on highlighting their technical skills, attention to detail, and problem-solving abilities. Here are some tips to help candidates prepare:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities and requirements of the Automatic Pattern Edger role.

- Review the company’s website and social media pages.

- Read industry news and articles related to pattern cutting and textile manufacturing.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating automatic pattern cutting machines. Include any experience with specific software or systems used in the industry.

- Quantify your accomplishments, such as the number of patterns cut or the percentage of accuracy achieved.

- Provide examples of how you have used your technical skills to solve problems or improve efficiency.

3. Showcase Your Attention to Detail

Demonstrate your ability to meticulously inspect fabric and identify defects. Highlight your commitment to producing high-quality products.

- Describe your experience in inspecting fabric for flaws and imperfections.

- Explain how you maintain a clean and organized work area to minimize errors.

4. Emphasize Your Problem-Solving Abilities

Share instances where you encountered challenges while operating the automatic pattern cutting machine. Discuss how you troubleshooting and resolved them.

- Provide specific examples of problems you have solved, such as machine malfunctions or inaccurate patterns.

- Explain your logical approach to problem-solving and how you prioritize tasks.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Pattern Edger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!