Are you gearing up for a career in Automatic Quilling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Quilling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

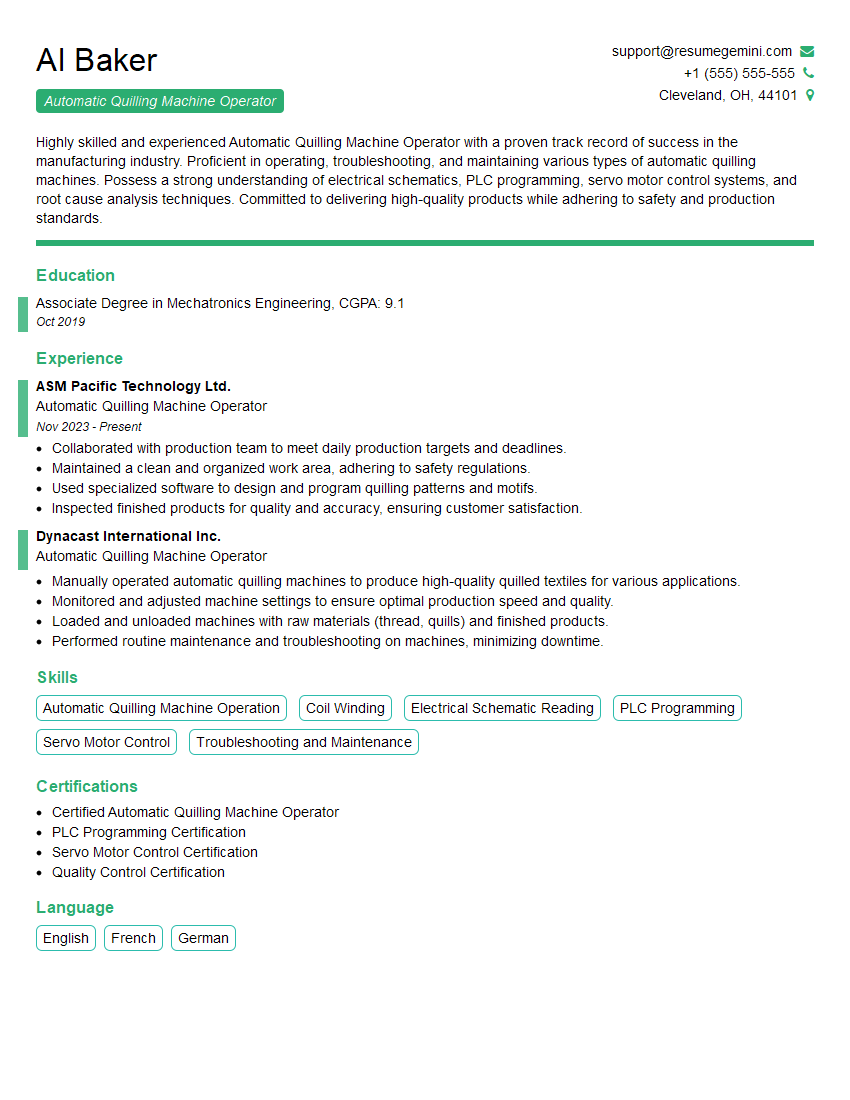

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Quilling Machine Operator

1. Explain the fundamental principles of quilling machine operation.

- Describe the process of loading paper strips into the machine and securing them in place.

- Explain how the machine forms the quills and the different types of quills that can be created.

- Discuss the importance of maintaining proper tension on the paper strips during operation.

2. Describe the various settings and controls on an automatic quilling machine.

Types of settings

- Speed settings

- Tension settings

- Strip width settings

Functions of controls

- Start/stop button

- Emergency stop button

- Jog buttons

3. Explain the maintenance procedures for an automatic quilling machine.

- Daily maintenance tasks (e.g., cleaning, lubrication)

- Weekly maintenance tasks (e.g., inspecting belts, checking sensors)

- Monthly maintenance tasks (e.g., replacing filters, calibrating sensors)

4. Describe the different types of paper strips used in quilling and their characteristics.

- Paper weight and thickness

- Paper texture and finish

- Paper color and pattern

5. Explain how to troubleshoot common problems with an automatic quilling machine.

- Paper jams

- Tension problems

- Electrical problems

6. Describe the different types of quilling projects that can be created with an automatic quilling machine.

- Jewelry and accessories

- Home décor

- Artwork

7. Explain the safety precautions that must be taken when operating an automatic quilling machine.

- Wearing appropriate safety gear (e.g., gloves, eye protection)

- Keeping the work area clean and free of debris

- Following the manufacturer’s instructions for safe operation

8. Describe the different types of adhesives used in quilling and their applications.

- Liquid adhesive

- White glue

- Mod Podge

9. Explain the different techniques used in quilling, such as shaping, layering, and embellishing.

Shaping techniques

- Curling

- Looping

- Rolling

Layering techniques

- Stacking

- Interlocking

- Overlapping

Embellishing techniques

- Adding beads or sequins

- Painting or coloring

- Using glitter or other decorative elements

10. Describe the different factors that affect the quality of a quilled project.

- The quality of the paper strips

- The tension on the paper strips

- The accuracy of the quilling machine

- The skill of the operator

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Quilling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Quilling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Quilling Machine Operator is responsible for operating a machine that produces quills, which are used in the production of textiles, such as bedspreads and tablecloths. The operator must be able to set up and maintain the machine, as well as monitor its operation to ensure that it is producing quills of the correct quality and quantity.

1. Set up and maintain the machine

The operator must be able to set up the machine according to the manufacturer’s specifications. This includes setting the correct tension on the thread, adjusting the speed of the machine, and setting the correct size and shape of the quills.

- Identify and resolve any problems that may occur with the machine, such as thread breaks, machine jams, or incorrect quill production.

- Perform regular maintenance on the machine, such as cleaning and lubricating it, to ensure that it is operating at peak efficiency.

2. Monitor the operation of the machine

The operator must be able to monitor the operation of the machine to ensure that it is producing quills of the correct quality and quantity. This includes checking the tension of the thread, the speed of the machine, and the size and shape of the quills.

- Monitor the quality of the quills being produced, ensuring that they meet the required specifications.

- Keep track of the number of quills produced, and ensure that the machine is meeting the production targets.

- Report any problems with the machine to the supervisor.

3. Clean and maintain the work area

The operator must be able to clean and maintain the work area to ensure that it is safe and free of debris. This includes cleaning the machine, sweeping the floor, and removing any waste materials.

- Keep the work area clean and organized, ensuring that it is free from any potential hazards.

- Follow all safety regulations and procedures, and wear appropriate safety gear when operating the machine.

- Report any safety concerns to the supervisor.

4. Follow safety procedures

The operator must be able to follow safety procedures to ensure that they are not injured while operating the machine. This includes wearing appropriate safety gear, following lockout/tagout procedures, and being aware of the potential hazards of the machine.

- Be aware of the potential hazards associated with operating the machine, and take appropriate precautions to avoid injury.

- Follow all safety regulations and procedures, and wear appropriate safety gear.

- Report any safety concerns to the supervisor.

Interview Tips

Here are some tips to help you ace your interview for an Automatic Quilling Machine Operator position:

1. Do your research

Before you go to your interview, take some time to research the company and the position. This will help you to understand the company’s culture and the specific requirements of the job. You should also be prepared to talk about your own experience and qualifications, and how they relate to the job.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get a sense of the company culture and employee satisfaction.

- Research the specific job title to learn about the typical responsibilities and qualifications.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief overview of your experience and qualifications, and how they relate to the job you are applying for.

- Think about why you are interested in the job and the company, and be prepared to articulate your reasons.

- Practice your answers to common interview questions with a friend or family member.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing excessive jewelry or perfume.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Avoid wearing excessive jewelry or perfume.

- Make sure your shoes are clean and polished.

4. Be on time

Punctuality is important, so be sure to arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know. It is also important to be prepared for the interview when you arrive. This means having your resume and other materials ready to go.

- Plan your route to the interview location in advance.

- Leave early to allow for unexpected delays.

- Bring a copy of your resume and other relevant materials.

5. Be confident and enthusiastic

It is important to be confident and enthusiastic during your interview. This will show the interviewer that you are interested in the job and that you have the skills and experience to be successful. Be sure to make eye contact with the interviewer and speak clearly and confidently.

- Maintain eye contact with the interviewer.

- Speak clearly and confidently.

- Smile and be enthusiastic.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Quilling Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.