Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automatic Riveting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

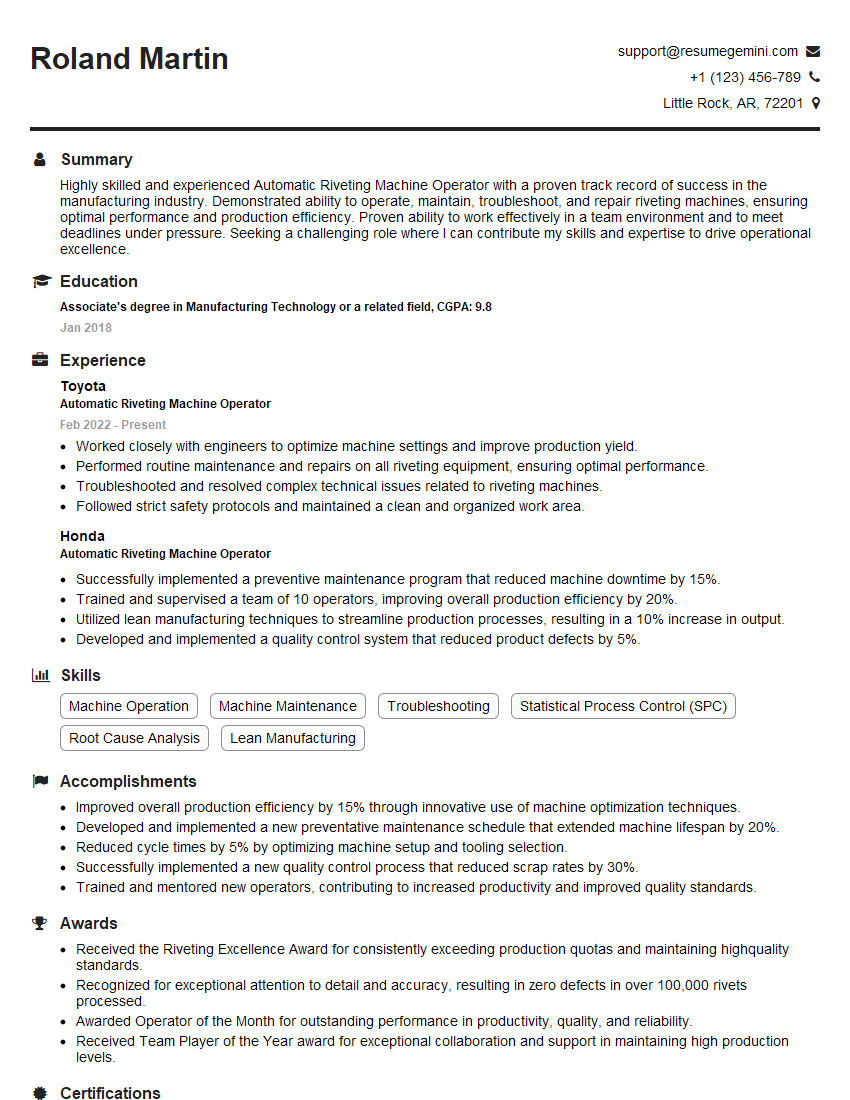

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Riveting Machine Operator

1. What are the different types of automatic riveting machines?

There are various types of automatic riveting machines, including:

- Pneumatic riveting machines: Use compressed air to drive the riveting process.

- Hydraulic riveting machines: Utilize hydraulic pressure to set rivets.

- Electric riveting machines: Employ electric motors to power the riveting operation.

- Electromagnetic riveting machines: Leverage electromagnetic force to join materials.

- Ultrasonic riveting machines: Generate high-frequency vibrations to create solid-state bonds.

2. Describe the key components of an automatic riveting machine.

Mechanical components:

- Frame: Supports and houses the machine’s components.

- Head: Contains the riveting mechanism, including the anvil and riveting tool.

- Feed system: Loads and positions the rivets.

- Drive system: Provides power to the riveting head.

Electrical components:

- Controller: Manages the machine’s operation.

- Sensors: Monitor the machine’s status and provide feedback.

- Safety devices: Ensure the safety of the operator.

3. What are the safety measures that should be followed when operating an automatic riveting machine?

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

- Ensure that the machine is properly grounded and maintained.

- Keep hands and loose clothing away from moving parts.

- Inspect the machine regularly for any damage or wear.

- Follow the manufacturer’s operating instructions and safety guidelines.

4. Explain how to troubleshoot common problems with automatic riveting machines.

- Rivets not setting properly: Check the anvil and riveting tool for wear or damage. Adjust the riveting force or feed rate.

- Machine not cycling properly: Inspect electrical connections, sensors, and the controller. Ensure that the air supply (if pneumatic) is adequate.

- Excessive noise or vibration: Check for loose components or worn bearings. Lubricate moving parts as necessary.

- Rivets jamming: Ensure that the feed system is working correctly and that the rivets are compatible with the machine.

5. What maintenance tasks are necessary for automatic riveting machines?

- Regular cleaning and lubrication of moving parts.

- Replacement of worn or damaged components, such as anvils and riveting tools.

- Calibration and adjustment of the machine settings.

- Inspection of electrical connections and safety devices.

- Following the manufacturer’s recommended maintenance schedule.

6. Describe the process of setting up an automatic riveting machine for a specific application.

- Select the appropriate riveting machine based on the material and rivet size.

- Install the correct anvil and riveting tool.

- Set the riveting force, feed rate, and cycle time according to the manufacturer’s specifications.

- Load the rivets into the feed system.

- Run a test cycle to ensure proper operation.

7. Explain how to optimize the efficiency of an automatic riveting machine.

- Properly maintain the machine to minimize downtime.

- Use high-quality rivets that are compatible with the machine.

- Optimize the riveting force and feed rate for each application.

- Reduce setup time by using quick-change tooling.

- Implement automated feeding systems to increase productivity.

8. What are the different types of rivets that can be used with automatic riveting machines?

- Solid rivets: Require drilling a hole and inserting the rivet, then deforming its tail to secure it.

- Blind rivets: Can be installed without access to the opposite side of the material.

- Self-piercing rivets: Create their own holes in the material as they are set.

- Tubular rivets: Have a hollow center that allows for expansion and secure joints with different material thicknesses.

9. How do you determine the correct size and type of rivet for a specific application?

- Consider the material thickness, joint strength requirements, and the environment in which the joint will be used.

- Refer to the manufacturer’s specifications for rivet sizes and types.

- Conduct tests to evaluate the performance of different rivets for the application.

10. What are the advantages of using automatic riveting machines over manual riveting?

- Increased productivity and efficiency.

- Consistent rivet quality and joint strength.

- Reduced labor costs and operator fatigue.

- Improved safety due to reduced exposure to repetitive motions.

- Ability to integrate with automated production lines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Riveting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Riveting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Riveting Machine Operator typically carries out the following key responsibilities:

1. Operate and Monitor Machinery

Setting up, operating, and monitoring automatic riveting machines to join metal or plastic components.

- Loading and unloading workpieces into designated areas.

- Adjusting machine settings for different types of rivets and materials.

2. Inspect and Maintain Equipment

Conducting regular inspections and preventive maintenance on riveting machines and related equipment.

- Identifying and resolving minor malfunctions or issues.

- Reporting major problems to supervisors for repair or replacement.

3. Ensure Quality Standards

Inspecting and verifying the quality of riveted joints to meet specified standards.

- Measuring and checking the strength and accuracy of rivets.

- Flagging or rejecting defective workpieces to prevent further processing.

4. Follow Safety Procedures

Adhering to established safety protocols while operating machinery.

- Wearing appropriate personal protective equipment (PPE).

- Maintaining a clean and organized work area to minimize hazards.

Interview Tips

To prepare for an interview for an Automatic Riveting Machine Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry.

- Visit the company website and social media pages.

- Search for news articles or recent press releases to gain insights into the company’s culture and priorities.

2. Practice Answering Common Questions

Prepare answers to typical interview questions related to your skills, experience, and motivations.

- Describe your experience operating and maintaining automatic riveting machines.

- How do you ensure that the riveted joints meet quality standards?

- What safety procedures do you follow when working with heavy machinery?

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, attention to detail, and ability to work in a fast-paced environment.

- Showcase your proficiency in adjusting machine settings for different materials and rivet sizes.

- Provide examples of how you have identified and resolved equipment issues.

- Discuss your experience in maintaining a safe and organized work area.

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer about the company, the position, and the work environment.

- Inquire about the company’s production goals and how they relate to the role.

- Ask about the training and development opportunities available for employees.

- Seek information about the company’s safety record and commitment to employee well-being.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Riveting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!