Are you gearing up for a career in Automatic Shirring Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Shirring Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

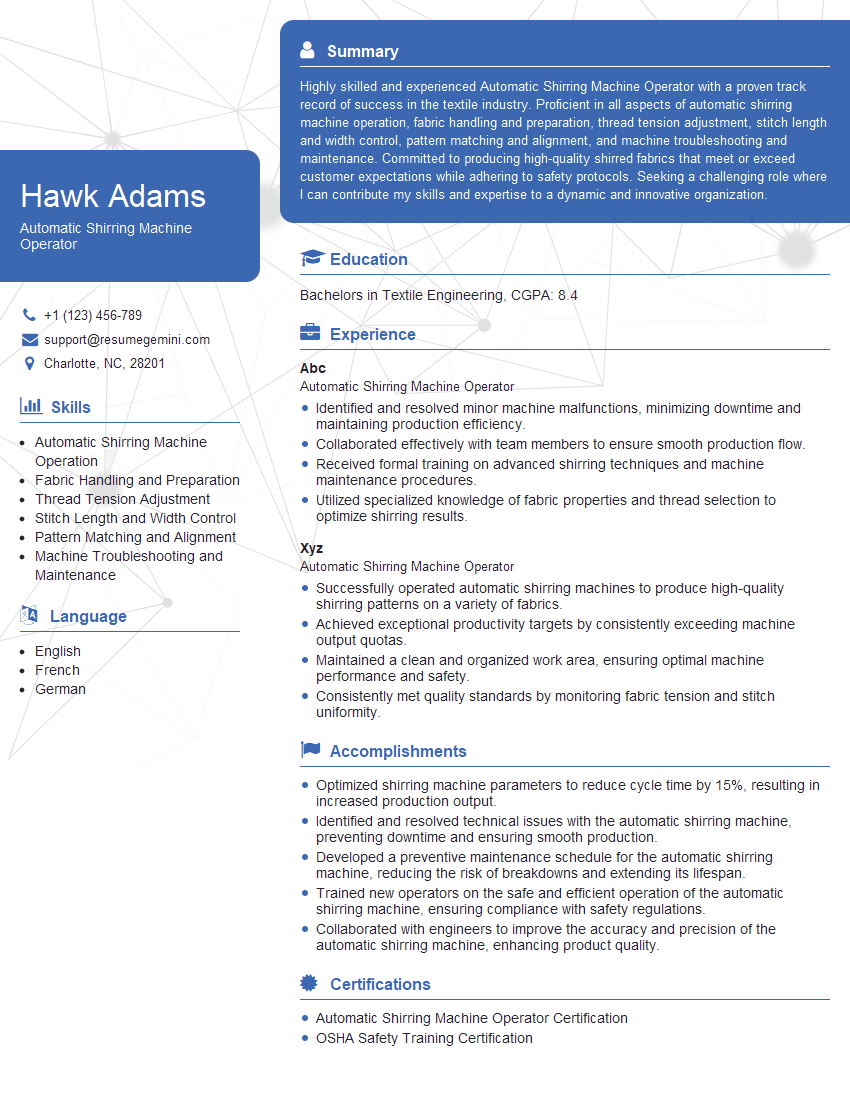

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Shirring Machine Operator

1. How do you ensure the accuracy of the shirring process?

- Check the tension of the thread and adjust it as needed to ensure the stitches are evenly distributed.

- Use a ruler or measuring tape to check the distance between the shirring stitches and adjust the machine settings accordingly.

- Regularly inspect the machine for any worn or damaged parts that could affect the accuracy of the shirring process.

2. What troubleshooting steps would you take if the machine produces uneven or loose shirring?

Check the thread tension

- Adjust the tension of the thread to ensure it is tight enough to create even shirring.

Check the needle

- Inspect the needle for any damage or wear and replace it if necessary.

Check the presser foot

- Ensure the presser foot is properly installed and adjusted to exert the correct amount of pressure on the fabric.

3. How do you maintain the automatic shirring machine to ensure optimal performance?

- Clean the machine regularly to remove any dust or debris that could interfere with its operation.

- Oil and lubricate the machine according to the manufacturer’s instructions to reduce friction and wear.

- Regularly inspect the machine for any worn or damaged parts and replace them as needed.

4. How do you determine the correct shirring settings for different types of fabric?

- Consider the thickness and weight of the fabric.

- Experiment with different shirring settings on a sample piece of fabric to determine the optimal settings.

- Consult the machine’s user manual or consult with a more experienced operator for guidance.

5. How do you handle machine breakdowns or malfunctions during production?

- Identify the problem and troubleshoot it using the machine’s user manual or by contacting a technician.

- If the problem cannot be resolved quickly, stop the machine and report it to a supervisor for assistance.

- Keep a record of any machine breakdowns or malfunctions for future reference and maintenance purposes.

6. What safety precautions should be taken when operating an automatic shirring machine?

- Wear appropriate safety gear, such as safety glasses and gloves.

- Keep hands and fingers away from moving parts of the machine.

- Never operate the machine if it is not properly grounded.

7. How do you ensure that the shirring process meets the desired specifications and quality standards?

- Check the shirring process regularly to ensure that the stitches are evenly distributed and meet the desired specifications.

- Use a quality control checklist to track the shirring process and identify any areas that need improvement.

- Consult with a supervisor or quality control department to ensure that the shirring process meets the required standards.

8. What are some of the challenges you have faced as an Automatic Shirring Machine Operator and how have you overcome them?

- Troubleshooting machine breakdowns and malfunctions: I have overcome this challenge by developing a strong understanding of the machine’s operation and by consulting with more experienced operators and technicians.

- Maintaining consistent shirring quality: I have overcome this challenge by paying close attention to the machine settings and by regularly checking the shirring process to ensure it meets the desired specifications.

9. Describe your experience with different types of shirring machines.

In my previous role as an Automatic Shirring Machine Operator, I operated a variety of shirring machines, including single-needle, double-needle, and multi-needle machines. I have experience with machines from different manufacturers, such as Juki, Brother, and Pegasus.

10. What are your strengths and weaknesses as an Automatic Shirring Machine Operator?

Strengths:

- Strong attention to detail and accuracy

- Ability to troubleshoot and resolve machine problems

- Experience with a variety of shirring machines

Weaknesses:

- Limited experience with automated shirring systems

- Need to improve speed and efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Shirring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Shirring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Shirring Machine Operator plays a crucial role in the production process, ensuring the efficient operation of automatic shirring machines to produce high-quality shirred fabrics. The key job responsibilities include:

1. Machine Operation and Maintenance

• Set up and operate automatic shirring machines according to specified production schedules and quality standards,

• Load fabric into the machine and adjust tension, stitch length, and other parameters,

• Monitor the machine during operation, making necessary adjustments to ensure optimal performance,

2. Quality Control

• Inspect shirred fabrics for defects, such as skipped stitches, thread breaks, or uneven shirring,

• Identify and correct machine malfunctions or adjust parameters to maintain quality standards,

• Work with quality control personnel to ensure the fabric meets customer specifications,

3. Machine Maintenance

• Perform routine maintenance on automatic shirring machines, including cleaning, lubrication, and minor repairs,

• Monitor machine performance and identify potential issues, reporting them to supervisors for further action,

• Assist with major repairs or overhauls as needed,

4. Production Support

• Work closely with production supervisors, quality control personnel, and other operators to ensure smooth production flow,

• Provide support to other operators during setup, changeovers, or troubleshooting,

• Participate in continuous improvement initiatives to enhance machine efficiency and quality,

Interview Tips

To ace an interview for an Automatic Shirring Machine Operator position, it is essential to be well-prepared and showcase your relevant skills and experience. Here are some interview preparation tips:

1. Research the Company and Position

• Familiarize yourself with the company’s website, industry, and product offerings,

• Understand the specific requirements of the Automatic Shirring Machine Operator role,

• Research industry trends and best practices related to automatic shirring machine operation,

2. Practice Your Skills

• Practice operating automatic shirring machines or similar equipment if possible,

• Prepare sample materials showcasing your shirring skills and attention to detail,

• Be ready to demonstrate your troubleshooting skills and knowledge of machine maintenance procedures,

3. Highlight Your Experience

• Quantify your accomplishments and provide specific examples of your contributions as an Automatic Shirring Machine Operator,

• Share your experience in meeting production targets, maintaining high quality standards, and resolving technical issues,

• Showcase your teamwork, problem-solving abilities, and commitment to continuous improvement,

4. Prepare Questions

• Prepare thoughtful questions about the company, the role, and the industry,

• This shows your interest, engagement, and that you have taken the time to research the position,

• Consider asking about the company’s growth plans, sustainability initiatives, or any technical advancements related to automatic shirring technology,

5. Be Confident and Professional

• Dress appropriately, arrive on time, and maintain a positive and enthusiastic demeanor,

• Use clear and concise language, articulate your skills and experience effectively,

• Be confident in your abilities and show that you are eager to contribute to the team,

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Shirring Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!