Are you gearing up for a career in Automatic Steel Tie Adjuster? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automatic Steel Tie Adjuster and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

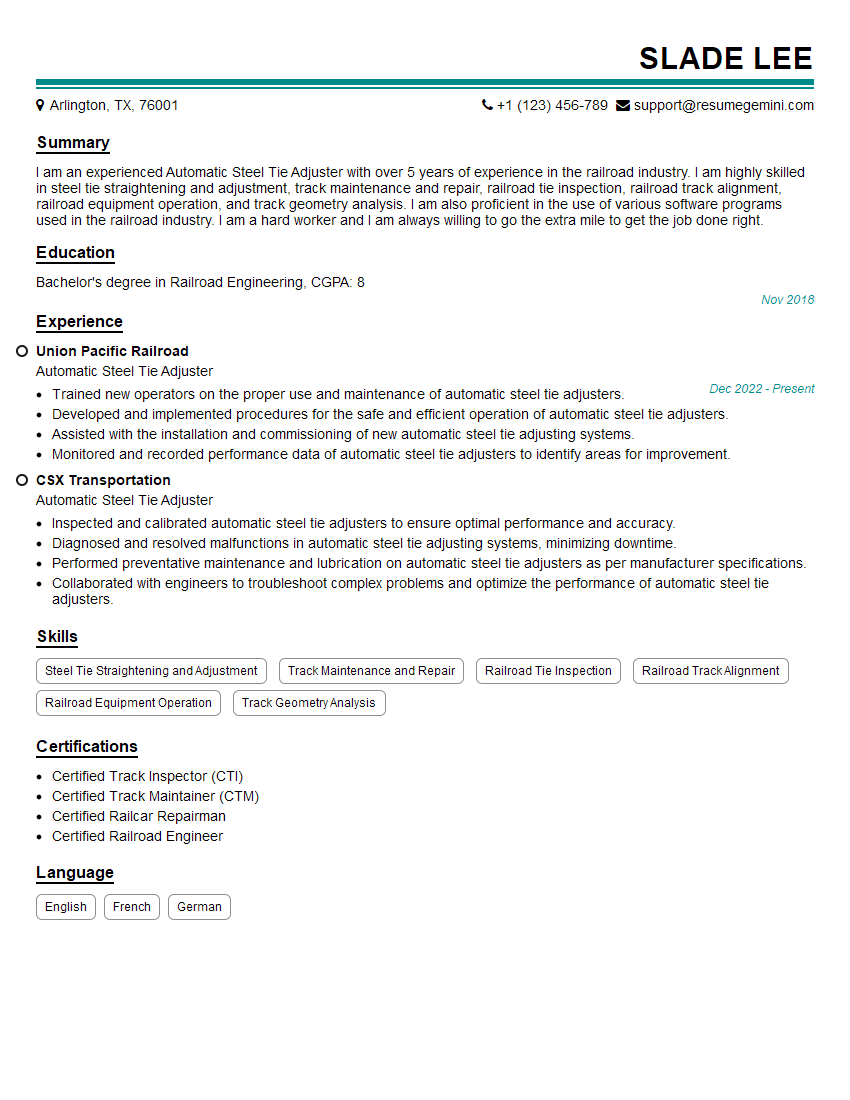

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Steel Tie Adjuster

1. Explain the working principle of an Automatic Steel Tie Adjuster?

An Automatic Steel Tie Adjuster (ASTA) operates on the principle of electro-hydraulic control, involving the following steps:

- Sensing: The ASTA uses sensors to detect the position of the steel ties relative to the running rails.

- Control: Based on the sensor readings, the ASTA’s controller calculates the required adjustments to align the ties.

- Actuation: The controller then sends signals to hydraulic actuators, which apply force to the ties to move them into the correct position.

2. Describe the key components of an ASTA?

- Sensors: Detect tie position and alignment.

- Controller: Processes sensor data and calculates adjustments.

- Actuators: Apply force to move the ties.

- Power Supply: Provides electrical power to the system.

- Hydraulic System: Transmits force from actuators to ties.

3. What are the advantages of using an ASTA?

- Improved Track Geometry: Ensures accurate alignment of ties, reducing track wear and derailment risk.

- Reduced Maintenance Costs: Automates tie adjustment, minimizing the need for manual labor and track closures.

- Increased Train Speed and Safety: Maintains optimal track conditions for higher speeds and improved safety.

- Extended Rail Life: Proper tie alignment reduces stress on the rails, extending their lifespan.

4. What are the different types of ASTAs available?

- On-Track ASTAs: Mounted directly on the track, requiring temporary track closures for installation.

- Off-Track ASTAs: Operated from a separate vehicle, allowing adjustments without disrupting train traffic.

- Hybrid ASTAs: Combine both on-track and off-track capabilities for flexibility.

5. How do you troubleshoot common issues with ASTAs?

- Sensor Malfunction: Check sensor connections, calibrate sensors, and replace if necessary.

- Actuator Failure: Inspect hydraulic lines, test actuators, and repair or replace components.

- Controller Problems: Diagnose errors using diagnostic tools, update software, and replace the controller if needed.

- Power Supply Issues: Check power connections, measure voltage levels, and inspect cables and terminals.

6. What are the safety precautions to consider when operating ASTAs?

- Follow Manufacturer’s Instructions: Adhere to the operating manual for safe handling and maintenance.

- Wear Personal Protective Equipment (PPE): Use safety glasses, gloves, and high-visibility vests.

- Inspect ASTAs Regularly: Check components for wear, damage, or defects before operation.

- Operate in Designated Areas: Stay clear of live tracks and railway equipment.

- Be Aware of Surroundings: Maintain situational awareness and communicate with other railway staff.

7. Describe the maintenance procedures for ASTAs?

- Daily Inspections: Check sensors, actuators, hydraulics, and power supply for proper operation.

- Regular Maintenance: Perform preventive maintenance tasks as specified by the manufacturer, including lubrication, fluid changes, and component replacements.

- Calibration: Calibrate sensors periodically to ensure accurate tie positioning.

- Software Updates: Install software updates as recommended by the manufacturer to address performance issues or introduce new features.

8. Explain the integration of ASTAs with other track maintenance systems?

- Track Recording Systems: ASTAs can receive data from track recording systems to identify areas requiring adjustment.

- Asset Management Systems: ASTAs can be integrated into asset management systems to track maintenance history and plan future interventions.

- Remote Monitoring Systems: ASTAs can be equipped with remote monitoring capabilities to provide real-time data on system status and performance.

9. How do you stay up-to-date with advancements in ASTA technology?

- Attend Industry Events: Participate in conferences, workshops, and exhibitions to learn about new technologies and trends.

- Read Technical Literature: Stay informed about advancements through industry journals, white papers, and technical articles.

- Network with Experts: Connect with engineers, researchers, and suppliers to share knowledge and discuss emerging technologies.

- Engage in Training: Seek out training opportunities to enhance skills and stay abreast of industry best practices.

10. Describe a challenging situation you faced while working with ASTAs?

In one instance, an ASTA encountered intermittent actuator failures during a track maintenance operation. Through troubleshooting, I identified a faulty sensor that was providing incorrect position data to the controller. I replaced the sensor, recalibrated the ASTA, and the system operated normally thereafter.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Steel Tie Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Steel Tie Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Steel Tie Adjuster is responsible for maintaining and repairing steel ties used in railroad tracks. Their key job responsibilities include:

1. Tie Adjustments

Checking and adjusting the alignment and spacing of steel ties

- Using specialized tools and equipment to make necessary adjustments

- Ensuring that ties are properly spaced and aligned for optimal track stability and safety

2. Tie Replacement

Replacing damaged or worn steel ties

- Identifying and removing defective ties

- Installing new ties and securing them in place

3. Track Inspection

Inspecting railroad tracks for potential issues

- Checking for loose or broken ties, damaged rails, and other hazards

- Identifying areas that require repair or maintenance

4. Preventive Maintenance

Performing preventive maintenance on steel ties and track components

- Lubricating moving parts and tightening bolts

- Inspecting and cleaning ties to prevent corrosion and wear

Interview Tips

To ace an interview for an Automatic Steel Tie Adjuster position, candidates should be well-prepared and demonstrate their knowledge and skills. Here are some interview tips:

1. Research the Company and Role

Research the railroad company and the specific role to gain insights into their operations, values, and requirements.

- Visit the company website, read industry news, and connect with current or former employees to gather information.

- Carefully review the job description and identify the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job. Quantify your accomplishments whenever possible.

- Showcase your knowledge of steel tie adjustment techniques, tie replacement procedures, and track inspection methods.

- Provide specific examples of your involvement in preventive maintenance and troubleshooting.

3. Demonstrate Safety Awareness

Railroad operations involve potential hazards, so it is crucial to emphasize your safety awareness and adherence to industry regulations.

- Explain your understanding of railroad safety protocols and your commitment to following them.

- Describe your experience in using personal protective equipment and working in a safe manner.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your qualifications.

- Why are you interested in this role?

- Tell me about your experience in steel tie adjustment.

- How do you prioritize safety in your work?

5. Ask Meaningful Questions

Asking well-informed questions at the end of the interview shows your engagement and interest in the role.

- Inquire about the company’s training and development programs.

- Ask about the company’s commitment to safety and innovation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Steel Tie Adjuster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.