Feeling lost in a sea of interview questions? Landed that dream interview for Automatic Thread Winder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automatic Thread Winder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

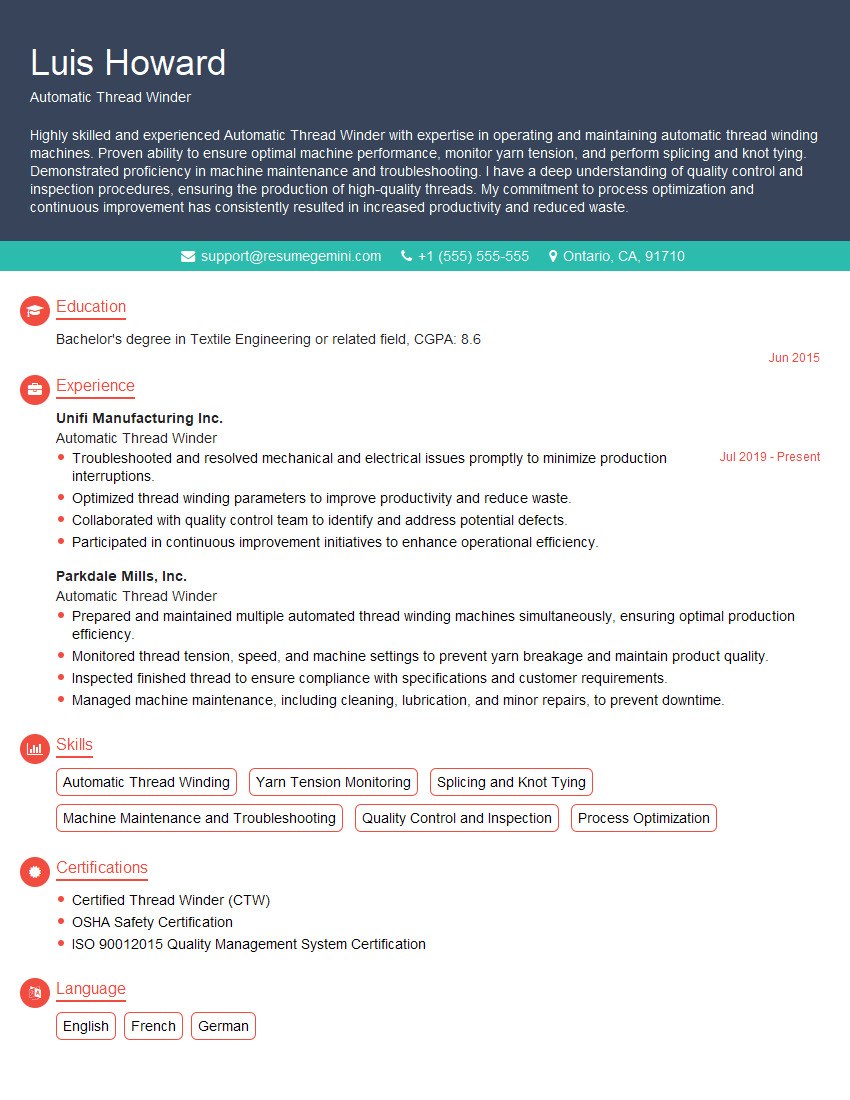

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Thread Winder

1. What are the different types of Automatic Thread Winders?

There are two main types of Automatic Thread Winders:

- Bobbin Winders: These winders are used to wind thread onto bobbins, which are then used in sewing machines.

- Cone Winders: These winders are used to wind thread onto cones, which are then used in embroidery machines.

2. What are the key components of an Automatic Thread Winder?

Mechanical Components

- Winding head

- Tension control

- Bobbin or cone holder

- Drive system

Electrical Components

- Motor

- Controller

- Sensors

3. How does an Automatic Thread Winder work?

An Automatic Thread Winder operates as follows:

- The thread is fed from a supply onto the winding head.

- The winding head rotates and winds the thread onto a bobbin or cone.

- The tension control ensures that the thread is wound with the correct tension.

- Sensors monitor the winding process and adjust the speed and tension as needed.

4. What are the factors that affect the quality of the wound thread?

- Thread quality

- Winding speed

- Tension control

- Environmental conditions (temperature and humidity)

5. What are the maintenance procedures for an Automatic Thread Winder?

- Cleaning the machine regularly

- Checking and replacing worn or damaged parts

- Calibrating the tension control

- Lubricating moving parts

6. What are the troubleshooting steps for an Automatic Thread Winder that is not working properly?

- Check the power supply

- Check the thread supply

- Check the tension control

- Check the sensors

- Check the motor and drive system

7. What are the safety precautions that should be taken when operating an Automatic Thread Winder?

- Keep hands away from moving parts

- Wear safety glasses

- Do not operate the machine if it is not properly grounded

- Follow the manufacturer’s instructions for safe operation

8. What are the industry standards for Automatic Thread Winders?

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

- OHSAS 18001: Occupational health and safety management systems

9. What are the latest trends in Automatic Thread Winding technology?

- Automated bobbin loading and unloading

- Laser-guided winding

- Sensor-based thread quality monitoring

- Remote monitoring and control

10. What is your experience with Automatic Thread Winders?

In my previous role as a Production Technician, I was responsible for operating and maintaining Automatic Thread Winders. I have experience with both bobbin and cone winders, and I am proficient in troubleshooting and repairing these machines. I am also familiar with the industry standards and safety precautions related to Automatic Thread Winders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Thread Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Thread Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Thread Winders are responsible for operating and maintaining automatic thread winding machines in a textile manufacturing plant. They are tasked with monitoring the machines during operation, making necessary adjustments to parameters, and performing routine maintenance to ensure the smooth running of the winding process.

1. Machine Operation and Monitoring

The primary responsibility of an Automatic Thread Winder is to monitor and operate automatic thread winding machines. This involves:

- Loading empty bobbins onto the machine and securing the thread.

- Setting winding parameters, such as winding speed, tension, and traverse length.

- Monitoring the winding process and making adjustments as needed to ensure that the thread is wound correctly.

- Inspecting wound bobbins for defects and ensuring that they meet quality standards.

- Keeping a record of machine operating parameters and production output.

2. Machine Maintenance

Automatic Thread Winders are also responsible for performing routine maintenance on their machines. This includes:

- Cleaning and lubricating the machine regularly.

- Inspecting and replacing worn or damaged parts.

- Calibrating the machine to ensure accurate winding.

- Troubleshooting and resolving any technical issues that may arise.

- Keeping a maintenance log to document all maintenance activities performed.

3. Safety and Quality Assurance

In addition to machine operation and maintenance, Automatic Thread Winders are also responsible for ensuring safety and quality in their work. This includes:

- Following all safety protocols and procedures.

- Maintaining a clean and organized work area.

- Inspecting raw materials and finished products to ensure that they meet quality standards.

- Participating in ongoing quality improvement initiatives.

- Reporting any concerns or issues to their supervisor.

4. Teamwork and Communication

Automatic Thread Winders often work as part of a team, and effective communication is crucial. This involves:

- Coordinating with other team members to ensure that production schedules are met.

- Communicating any issues or concerns to their supervisor or other relevant personnel.

- Participating in regular team meetings to discuss production goals, safety concerns, and other relevant topics.

- Providing support and assistance to other team members when needed.

- Maintaining a positive and collaborative work environment.

Interview Tips

Preparing for an interview for an Automatic Thread Winder position can be daunting, but following some simple tips can help you ace it. Here are some helpful strategies:

1. Research the Company and Role

Take the time to learn about the company you’re applying to, including their values, goals, and industry reputation. Familiarize yourself with the specific job responsibilities and qualifications required for the Automatic Thread Winder position.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples that demonstrate your skills and experience.

3. Highlight Relevant Skills and Experience

Emphasize your experience and skills that are relevant to the job description. For instance, highlight your knowledge of automatic thread winding machines, your ability to perform routine maintenance, and your commitment to safety and quality.

4. Demonstrate Your Teamwork and Communication Skills

Automatic Thread Winders often work in teams, so interviewers will be interested in your teamwork and communication skills. Share examples of how you effectively collaborated with others, resolved conflicts, and contributed to a positive work environment.

5. Ask Thoughtful Questions

At the end of the interview, interviewers typically ask if you have any questions. This is your chance to show your interest in the position and the company. Prepare a few thoughtful questions that demonstrate your enthusiasm and desire to learn more about the role and organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Thread Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!