Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Trimming Sewer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Trimming Sewer so you can tailor your answers to impress potential employers.

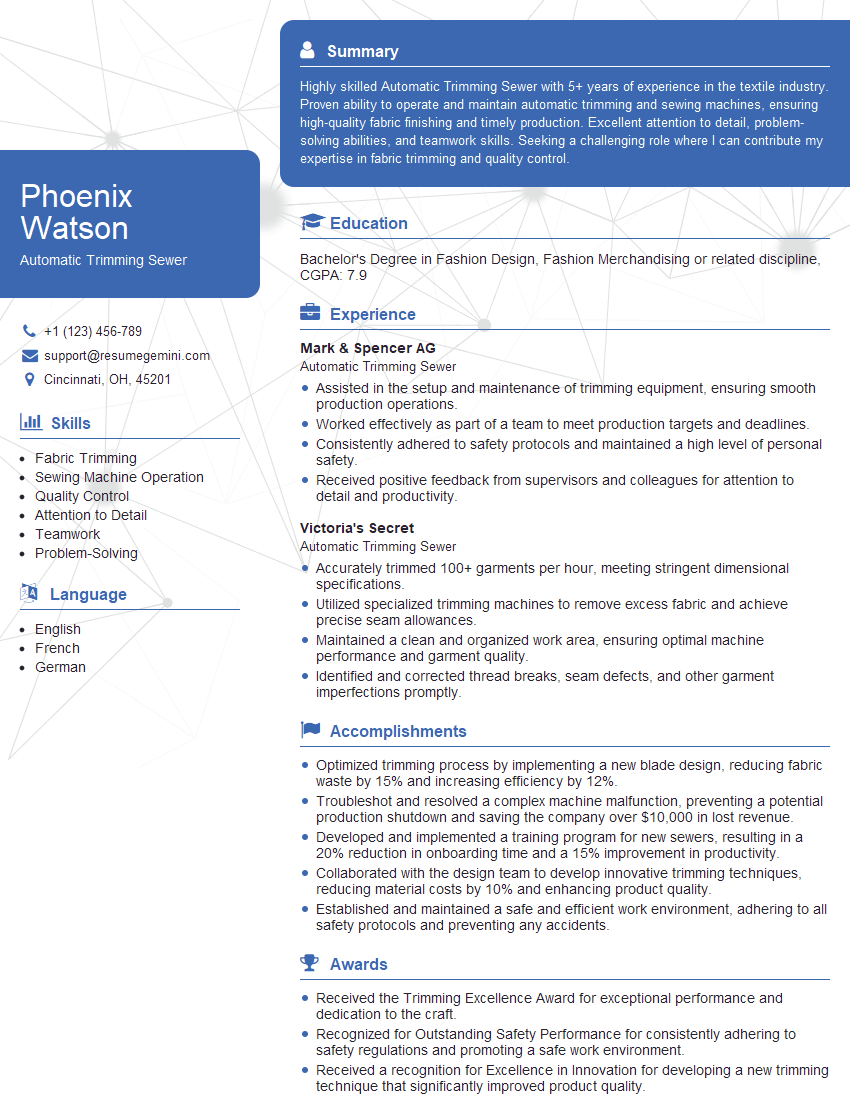

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Trimming Sewer

1. Describe the various types of automatic trimming sewers and their applications?

There are several types of automatic trimming sewers, each designed for specific applications:

- Vertical Trimming Sewers: Used for trimming the top and bottom edges of garments, such as T-shirts, sweatshirts, and sweaters.

- Horizontal Trimming Sewers: Designed for trimming the side edges of garments, such as dresses, skirts, and pants.

- Computerized Trimming Sewers: Equipped with computer-controlled systems for precise trimming and pattern matching, used in high-volume production environments.

- Thermal Trimming Sewers: Use heat to cut and seal the edges of fabrics, resulting in clean and fray-free finishes.

- Laser Trimming Sewers: Employ laser technology for precise and intricate trimming, ideal for delicate fabrics and complex designs.

2. Explain the key components and functions of an automatic trimming sewer?

Mechanical Components:

- Conveyor belt: Transports the fabric through the machine.

- Cutting blade or laser: Trims the fabric edges.

- Presser foot: Holds the fabric in place during trimming.

Electrical Components:

- Motor: Drives the conveyor belt and cutting mechanism.

- Controller: Regulates the speed and precision of the cutting operation.

- Sensors: Detect the fabric’s position and guide the cutting process.

3. Discuss the different types of fabrics that can be trimmed on an automatic trimming sewer?

- Woven fabrics: Cotton, linen, silk, etc.

- Knitted fabrics: Jersey, fleece, etc.

- Elastic fabrics: Spandex, lycra, etc.

- Delicate fabrics: Lace, chiffon, etc.

- Coated fabrics: PU, PVC, etc.

4. Describe the maintenance procedures required for an automatic trimming sewer?

- Regular cleaning: Remove dust, fabric scraps, and other debris.

- Blade sharpening: Replace or sharpen dull blades to ensure precision cutting.

- Lubrication: Apply lubricant to moving parts to prevent wear and tear.

- Software updates: Install software updates to optimize performance and address any issues.

- Electrical inspections: Ensure proper wiring and connections to prevent electrical hazards.

5. Explain how to troubleshoot common problems encountered on an automatic trimming sewer?

- Uneven trimming: Check for dull blades, conveyor belt misalignment, or fabric tension issues.

- Missed trims: Inspect sensors for proper alignment and calibration.

- Fabric snagging: Adjust the presser foot height or tension to prevent fabric puckering.

- Electrical faults: Check for loose connections, damaged wires, or faulty components.

- Software errors: Contact the manufacturer for assistance or perform software updates.

6. Discuss the safety precautions that should be taken when operating an automatic trimming sewer?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands away from the cutting area while the machine is operating.

- Ensure the machine is properly grounded to prevent electrical accidents.

- Never attempt to repair or adjust the machine while it is running.

- Follow the manufacturer’s instructions and safety guidelines.

7. Describe how the speed and accuracy of an automatic trimming sewer impact production efficiency?

- High speed: Reduces production time, increasing output and efficiency.

- High accuracy: Minimizes trimming errors, resulting in consistent product quality and reduced waste.

- Precision cuts: Enables intricate and precise trimming, reducing the need for manual finishing.

- Automated process: Automates the trimming process, eliminating manual labor and reducing production costs.

- Batch processing: Allows for efficient processing of large batches of fabrics, maximizing production capacity.

8. Explain the role of software in modern automatic trimming sewers?

- Cutting path optimization: Optimizes the cutting path to minimize fabric waste and maximize yield.

- Pattern matching: Ensures accurate alignment and matching of fabric patterns.

- Interface customization: Allows operators to customize the machine interface for ease of use and increased productivity.

- Data logging: Records production data for analysis and quality control purposes.

- Diagnostics and troubleshooting: Provides diagnostic tools to assist in troubleshooting and resolving machine issues.

9. Discuss the latest advancements in automatic trimming sewer technology?

- Artificial intelligence (AI) integration: Enables the machine to learn and adapt to different fabric types and cutting patterns.

- Vision systems: Utilize cameras to scan fabrics and detect defects, ensuring accurate trimming.

- Cloud connectivity: Allows for remote monitoring and updates, improving machine uptime and efficiency.

- Advanced sensors: Monitor fabric tension, temperature, and other parameters to ensure optimal cutting conditions.

- Sustainable features: Incorporate energy-saving technologies and reduce fabric waste, promoting environmental sustainability.

10. Describe the key factors to consider when selecting an automatic trimming sewer for a specific application?

- Fabric type: Match the machine’s capabilities to the specific fabrics being processed.

- Production volume: Consider the required production output and choose a machine with the appropriate speed and capacity.

- Accuracy requirements: Determine the level of precision required for the desired trimming quality.

- Features and software: Evaluate the available features and software capabilities to meet specific production needs.

- Cost and return on investment: Consider the initial investment and potential return on investment based on increased efficiency and reduced costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Trimming Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Trimming Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Trimming Sewer is responsible for operating and maintaining automatic trimming machines, which trim excess fabric from sewn garments. This role requires a keen eye for detail, precision, and a strong mechanical aptitude.

1. Machine Operation and Maintenance

The Automatic Trimming Sewer’s primary responsibility is to operate the automatic trimming machine effectively. This includes setting up the machine, loading garments, and adjusting settings to ensure accurate cutting.

- Set up and adjust the automatic trimming machine according to garment specifications.

- Load garments onto the machine and ensure proper alignment.

- Monitor the cutting process and make necessary adjustments to maintain accuracy and quality.

- Perform routine maintenance tasks on the trimming machine, including cleaning, lubrication, and minor repairs.

2. Quality Control

The Automatic Trimming Sewer is responsible for ensuring the quality of trimmed garments. This involves inspecting garments for defects, such as uneven cuts, missed stitches, or fabric damage.

- Inspect trimmed garments for defects and ensure they meet quality standards.

- Identify and report any issues with the trimming process or machine to the supervisor.

- Reprocess garments that do not meet quality standards.

- Maintain records of inspection results and any corrective actions taken.

3. Production Efficiency

The Automatic Trimming Sewer is expected to maintain a high level of production efficiency. This involves optimizing the trimming process, reducing waste, and meeting production targets.

- Maximize machine utilization and minimize downtime.

- Identify and implement ways to reduce fabric waste and improve efficiency.

- Meet production targets and deadlines while maintaining quality standards.

- Work effectively as part of a team to achieve production goals.

4. Safety and Compliance

The Automatic Trimming Sewer must adhere to all safety regulations and guidelines. This includes proper use of machinery, wearing appropriate safety gear, and maintaining a clean and organized work area.

- Follow all established safety procedures and guidelines.

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Maintain a clean and organized work area to prevent accidents and injuries.

- Report any safety concerns or potential hazards to the supervisor.

Interview Tips

Interviewing for an Automatic Trimming Sewer position requires preparation and a clear understanding of the role and your qualifications. Here are a few tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company you are applying to, its products or services, and the specific role of an Automatic Trimming Sewer. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Your Skills and Experience

Emphasize your skills and experience that are most relevant to the key responsibilities of the Automatic Trimming Sewer. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Anticipate questions about your experience, skills, and why you are interested in the position. You can also prepare questions to ask the interviewer, which shows your engagement and interest.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This demonstrates your respect for the company and the interviewer’s time.

5. Follow Up

After the interview, follow up with a thank-you note to reiterate your interest in the position and express your appreciation for the interviewer’s time. This is a simple but effective way to leave a positive lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Trimming Sewer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!