Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automatic Vulcanizing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

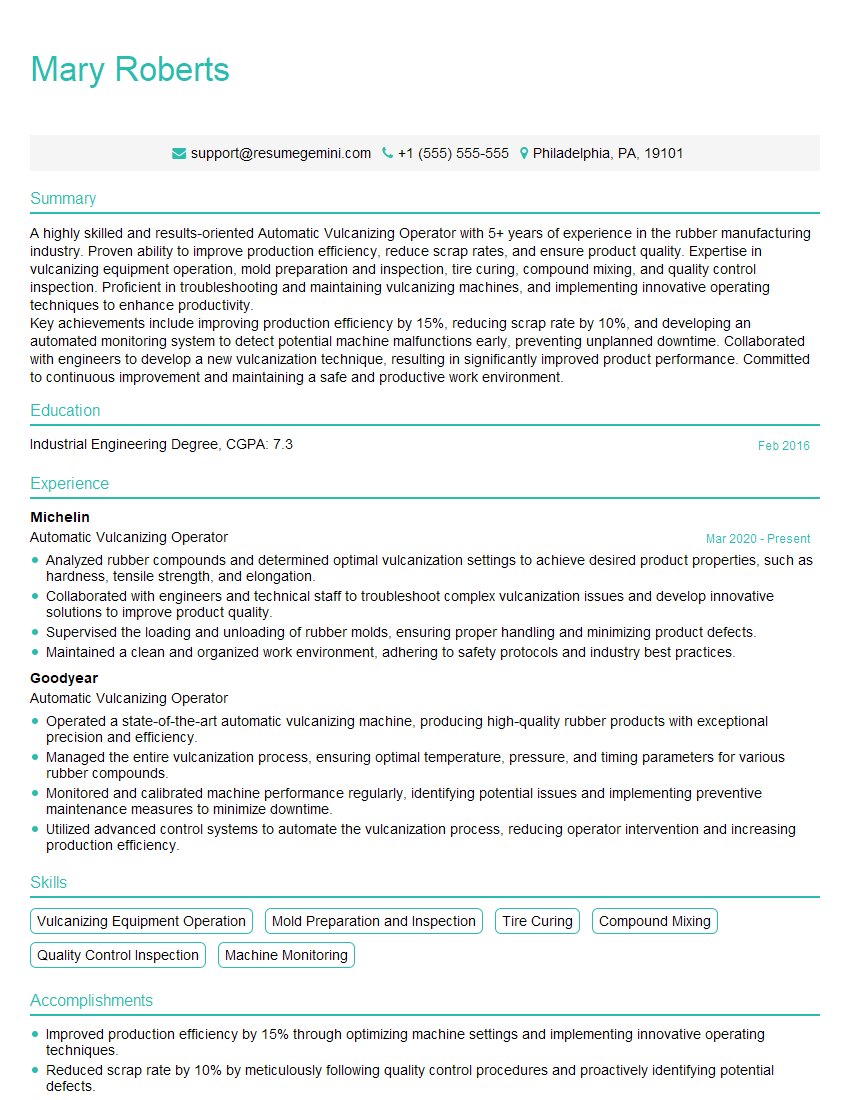

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Vulcanizing Operator

1. Describe the steps involved in the vulcanization process?

The vulcanization process involves several key steps:

- Preparation: The rubber compound is prepared by mixing raw rubber with various additives and chemicals.

- Shaping: The prepared rubber compound is shaped into the desired product using molds or extrusion machines.

- Vulcanization: The shaped rubber is subjected to heat and pressure in the presence of a vulcanizing agent (usually sulfur) to form cross-links between the rubber molecules, improving its strength and durability.

- Post-treatment: The vulcanized rubber product may undergo additional processing, such as trimming, finishing, or testing to ensure its quality.

2. What are the different types of vulcanization methods, and their advantages and disadvantages?

Hot vulcanization

- Advantages: Fast process, high efficiency, good mechanical properties.

- Disadvantages: High energy consumption, potential for over-vulcanization.

Cold vulcanization

- Advantages: Lower energy consumption, reduced risk of over-vulcanization, suitable for intricate shapes.

- Disadvantages: Slower process, lower efficiency, may require additional processing.

Microwave vulcanization

- Advantages: Rapid heating, uniform curing, low energy consumption.

- Disadvantages: Requires specialized equipment, may not be suitable for all rubber compounds.

3. How do you ensure the quality of vulcanized products?

Ensuring the quality of vulcanized products requires a comprehensive approach:

- Raw material inspection: Verifying the quality of raw materials before use.

- Process control: Monitoring and controlling process parameters, such as temperature, pressure, and time, to achieve optimal results.

- Testing and analysis: Conducting regular tests on the vulcanized products to evaluate their physical and mechanical properties, such as tensile strength, elongation at break, and hardness.

- Compliance with standards: Adhering to industry standards and regulations related to vulcanized products.

4. What are the common defects that can occur during vulcanization, and how can you prevent them?

Common defects during vulcanization include:

- Over-vulcanization: Excessive cross-linking, resulting in reduced elasticity and increased stiffness.

- Under-vulcanization: Insufficient cross-linking, leading to reduced strength and durability.

- Scorching: Degradation of rubber due to excessive heat exposure.

- Gas entrapment: Formation of air pockets within the vulcanized product, affecting its integrity.

Preventing these defects involves:

- Proper control of vulcanization temperature and time.

- Use of appropriate vulcanizing agents and accelerators.

- Adequate degassing of the rubber compound before vulcanization.

- Regular maintenance and calibration of vulcanizing equipment.

5. Describe the role of temperature and pressure in vulcanization?

Temperature and pressure play crucial roles in the vulcanization process:

- Temperature: Elevating the temperature increases the molecular mobility, facilitating the formation of cross-links.

- Pressure: Applying pressure ensures intimate contact between the rubber molecules, promoting cross-linking and reducing voids.

Optimal temperature and pressure conditions vary depending on the specific rubber compound and desired properties.

6. Explain the purpose and operation of an automatic vulcanizing press?

An automatic vulcanizing press is a machine designed to efficiently vulcanize rubber products:

- Purpose: It applies heat and pressure for a predetermined time to promote cross-linking in the rubber compound.

- Operation: The press consists of a heated platen that presses against a mold containing the uncured rubber. Automated controls regulate temperature, pressure, and cycle time.

7. How do you troubleshoot common problems with an automatic vulcanizing press?

- Low curing temperature: Check heating elements, temperature sensors, and controllers.

- Insufficient pressure: Inspect hydraulic or pneumatic systems, pressure gauges, and seals.

- Cycle time issues: Verify timer settings, control system, and sensor functionality.

- Leaking molds: Examine mold surfaces for damage or wear, and ensure proper mold alignment.

8. Describe the safety precautions that must be observed when operating an automatic vulcanizing press?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure the press is properly grounded and guarded.

- Follow established operating procedures and avoid touching hot surfaces.

- Never place hands or fingers between the platens or in the mold area.

- Report any unusual noises, vibrations, or leaks to a supervisor immediately.

9. How do you maintain an automatic vulcanizing press to ensure optimal performance?

- Regularly inspect and clean the press, including platens, molds, and sensors.

- Lubricate moving parts and check hydraulic or pneumatic systems for leaks.

- Calibrate temperature and pressure gauges periodically.

- Monitor and replace worn or damaged components as needed.

- Follow manufacturer’s maintenance guidelines and schedule routine preventive maintenance.

10. What is your understanding of the different types of rubber compounds, and how do they affect the vulcanization process?

Rubber compounds consist of various natural or synthetic rubbers, fillers, additives, and vulcanizing agents:

- Natural rubber: Derived from latex, it offers good elasticity and flexibility.

- Synthetic rubber: Engineered to meet specific performance requirements, such as resistance to heat, oil, or chemicals.

- Fillers: Enhance strength, reduce costs, or improve certain properties (e.g., carbon black for enhanced conductivity).

- Additives: Improve processing, reduce aging, or impart special characteristics.

- Vulcanizing agents: Facilitate the cross-linking process, improving durability and strength.

The type and proportions of these components influence the vulcanization process and the final properties of the rubber product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Vulcanizing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Vulcanizing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automatic Vulcanizing Operators are responsible for operating and maintaining vulcanizing equipment to produce high-quality rubber products. Their primary duties include:

1. Machine Operation

• Set up and operate automatic vulcanizing machines according to specifications.

• Monitor machine performance, adjust settings, and make necessary repairs.

2. Production Quality

• Inspect raw materials and finished products to ensure quality standards are met.

• Troubleshoot and resolve production issues to minimize downtime.

3. Safety and Maintenance

• Adhere to safety protocols and maintain a clean and organized work environment.

• Perform routine maintenance and repairs on vulcanizing equipment.

4. Record Keeping

• Maintain accurate records of production, machine performance, and quality control.

• Report any deviations or concerns to supervisors.

Interview Tips

To ace an interview for an Automatic Vulcanizing Operator position, candidates should focus on the following:

1. Technical Expertise

• Highlight your experience in operating and maintaining vulcanizing machines.

• Demonstrate your knowledge of vulcanizing processes and safety regulations.

2. Problem-Solving Skills

• Emphasize your ability to identify and resolve production issues efficiently.

• Provide examples of how you have used troubleshooting techniques to minimize downtime.

3. Quality Control

• Describe your experience in inspecting and maintaining the quality of rubber products.

• Explain your understanding of industry standards and quality control procedures.

4. Attention to Detail

• Emphasize your ability to follow instructions precisely and maintain a high level of accuracy.

• Highlight your experience in record-keeping and maintaining organized workspaces.

5. Safety Consciousness

• Demonstrate your commitment to safety and compliance with industry regulations.

• Describe your experience in adhering to safety protocols and maintaining a hazard-free work environment.

Next Step:

Now that you’re armed with the knowledge of Automatic Vulcanizing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Vulcanizing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini