Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Winder Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Winder Operator so you can tailor your answers to impress potential employers.

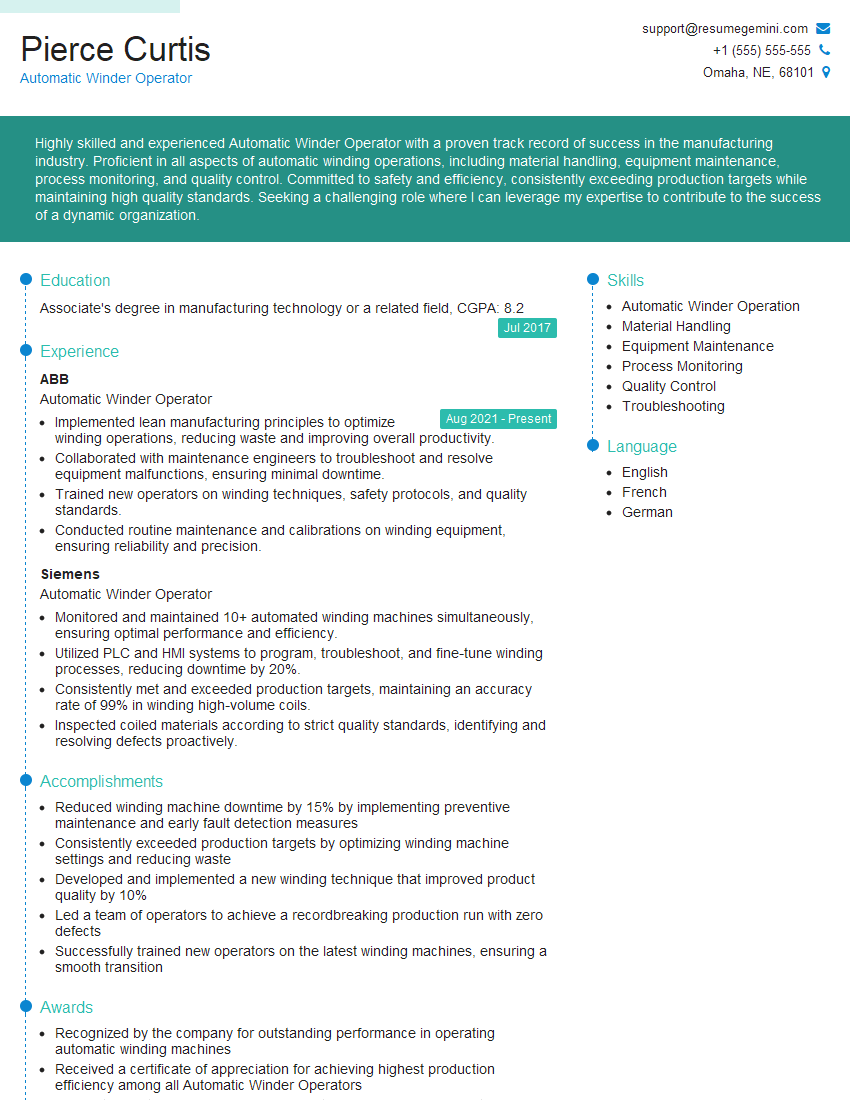

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Winder Operator

1. What are the primary duties of an Automatic Winder Operator?

- Monitor and operate automatic winding machines to wind yarn onto bobbins or spools

- Set up and adjust machines according to specified parameters

- Inspect wound yarn for defects and make adjustments as needed

- Maintain accurate inventory of yarn and supplies

- Follow safety protocols and industry best practices

2. What types of winding machines are you familiar with?

Machines with different spindle configurations

- Conventional winding machines with fixed spindles

- Automatic cone winding machines with rotating spindles

Machines with specialized functions

- Section warping machines for creating sectional beams

- Precision winding machines for high-performance applications

3. How do you ensure the quality of the wound yarn?

- Inspect yarn for defects before winding, such as knots, slubs, or broken strands

- Monitor machine settings and make adjustments as needed to maintain consistent tension and winding density

- Conduct regular quality checks throughout the winding process

- Identify and troubleshoot any issues that may affect yarn quality

4. What is the importance of proper tension control in automatic winding?

- Maintains yarn strength and prevents breakage

- Ensures uniform winding density and consistency

- Reduces yarn defects and improves overall quality

- Optimizes machine efficiency and productivity

5. How do you handle machine breakdowns and malfunctions?

- Identify the source of the issue quickly and accurately

- Follow established troubleshooting protocols

- Use appropriate tools and techniques to repair or replace faulty components

- Communicate with supervisors and maintenance personnel as needed

- Document all repairs and maintenance activities

6. What are the safety precautions to consider when operating automatic winding machines?

- Wear appropriate personal protective equipment, such as safety glasses and earplugs

- Maintain a clean and organized work area

- Never operate machines with loose clothing or jewelry

- Follow lockout/tagout procedures before performing any maintenance or repairs

- Report any unsafe conditions or practices immediately

7. How do you maintain and calibrate automatic winding machines?

- Follow manufacturer’s recommended maintenance schedules

- Lubricate moving parts and replace worn components as needed

- Calibrate machines regularly to ensure accurate winding and tension control

- Keep detailed maintenance logs and records

8. What are the different types of yarn materials that can be wound on automatic winding machines?

- Natural fibers: cotton, wool, linen

- Synthetic fibers: polyester, nylon, acrylic

- Blended fibers: combinations of natural and synthetic fibers

- Specialty fibers: carbon fiber, glass fiber, aramid fiber

9. What is the role of a quality control inspector in the automatic winding process?

- Inspect raw materials and finished products for defects

- Monitor winding parameters and ensure they meet specifications

- Conduct random sampling and testing to verify product quality

- Provide feedback to operators and supervisors on quality issues

- Maintain accurate quality control records

10. How do you stay up-to-date with the latest advancements in automatic winding technology?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Participate in online forums and discussion groups

- Seek training from equipment manufacturers and industry experts

- Explore new technologies and innovative solutions to improve efficiency and quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Winder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Winder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Winder Operator is responsible for the upkeep and smooth functioning of automatic winding machines within a manufacturing facility. Their core duties encompass the operation, monitoring, and maintenance of these machines to ensure optimal yarn winding and quality control. This role demands a high level of precision, attention to detail, and adherence to safety protocols.

1. Machine Operation

Execute seamless operation of automatic winding machines, ensuring proper yarn winding onto bobbins.

- Set up and configure winding machines based on specific yarn requirements.

- Monitor machine performance, making necessary adjustments to optimize efficiency and maintain product quality.

2. Quality Control

Inspect and ensure the quality of yarn wound on bobbins, adhering to established standards.

- Carry out regular quality checks to identify defects or inconsistencies in yarn winding.

- Implement corrective actions to resolve any quality issues promptly.

3. Machine Maintenance

Perform routine maintenance tasks to ensure the proper functioning of winding machines.

- Clean and lubricate machine components as per prescribed maintenance schedules.

- Inspect and identify potential mechanical issues, reporting them to the supervisor.

4. Safety Compliance

Maintain a safe work environment by adhering to established safety protocols.

- Follow proper lockout/tagout procedures during maintenance operations.

- Wear appropriate personal protective equipment (PPE) at all times.

Interview Tips

To ace the interview for an Automatic Winder Operator position, it is essential to showcase your technical skills, attention to detail, and safety consciousness. Moreover, highlighting your willingness to learn and adapt to new technologies will demonstrate your commitment to professional growth. Here are some key preparation tips:

1. Research the Company and Role

Familiarize yourself with the company’s core values, mission, and recent developments. Understand the specific requirements of the Automatic Winder Operator role and tailor your responses accordingly.

- Visit the company’s website to gather information about their operations and industry standing.

- Review the job description thoroughly to identify essential responsibilities and qualifications.

2. Practice Common Interview Questions

Prepare for common interview questions and rehearse your answers to sound confident and articulate. Anticipate questions related to your experience with winding machines, quality control measures, and safety protocols.

- Practice answering questions about your technical skills and proficiency with winding machine operations.

- Prepare examples of how you have ensured yarn quality and resolved any winding issues in previous roles.

3. Highlight Your Safety Consciousness

Emphasize your commitment to workplace safety by highlighting your knowledge of relevant safety protocols and your dedication to following them strictly. Mention any safety certifications or training you have received.

- Discuss your understanding of the importance of lockout/tagout procedures and their role in accident prevention.

- Share examples of how you have maintained a clean and organized work environment to minimize potential hazards.

4. Showcase Your Adaptability and Willingness to Learn

Convey your readiness to embrace new technologies and your ability to adapt to changing work environments. Demonstrate your eagerness to learn and grow within the field.

- Mention your interest in staying updated with the latest advancements in winding machine technology.

- Express your willingness to undergo training and development programs to enhance your skills.

Next Step:

Now that you’re armed with the knowledge of Automatic Winder Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automatic Winder Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini