Are you gearing up for a career in Automation Engineering Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Automation Engineering Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

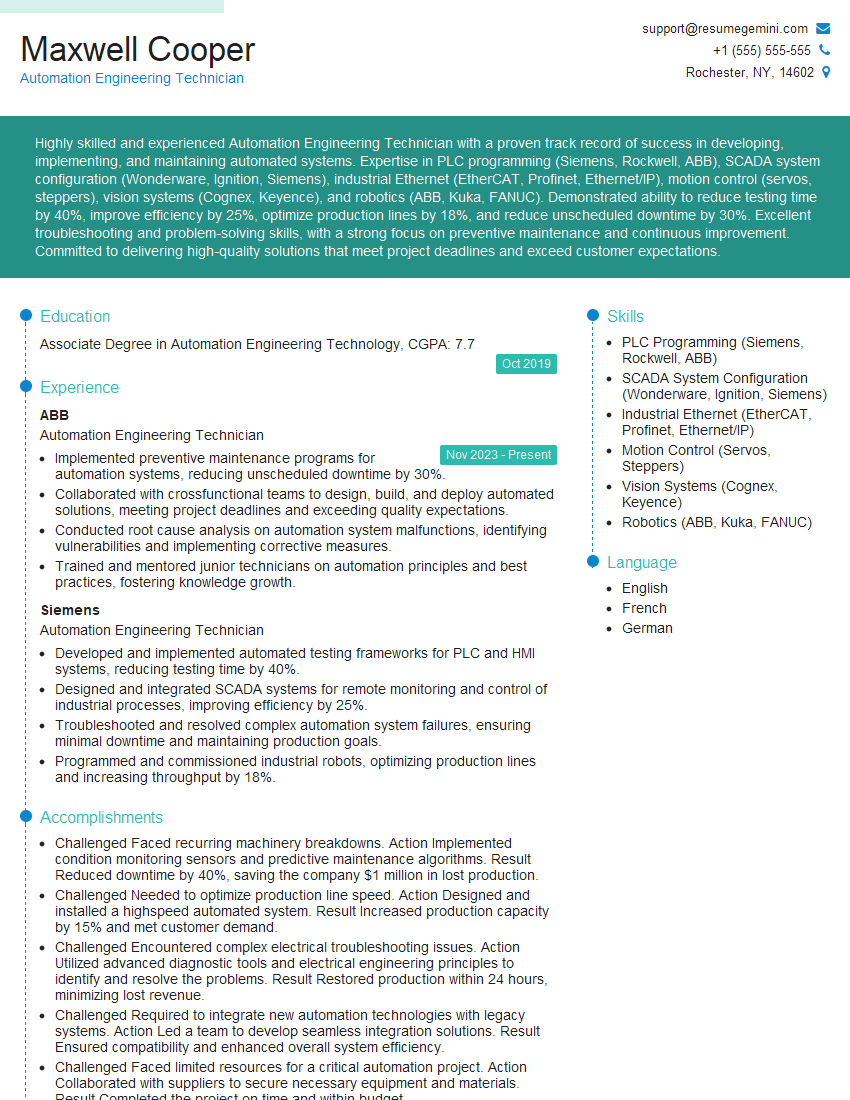

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automation Engineering Technician

1. Describe the different types of automation systems you have worked with, and what were their key features?

I have worked with various types of automation systems, including:

- Programmable Logic Controllers (PLCs): These are industrial computers that control processes and machines in factories. They are typically used for simple and mid-level automation tasks.

- Distributed Control Systems (DCSs): These are large-scale control systems used in complex industrial processes, such as power plants and chemical plants. They provide high levels of control and monitoring.

- Supervisory Control and Data Acquisition (SCADA) systems: These systems are used to monitor and control industrial processes from a central location. They provide real-time data and alarms, allowing operators to make informed decisions.

2. Explain the difference between open-loop and closed-loop control systems, and give examples of each.

Open-Loop Control Systems

- Do not have feedback from the output

- Output is not dependent on the input

- Example: A simple thermostat that turns on the heater when the temperature drops below a certain point

Closed-Loop Control Systems

- Have feedback from the output

- Output is dependent on the input

- Example: A temperature control system that uses a sensor to measure the temperature and adjusts the heater to maintain the desired temperature

3. What are the advantages and disadvantages of using PLCs in automation systems?

Advantages

- Compact and rugged

- Easy to install and maintain

- Flexible and can be used for a variety of applications

- Cost-effective

Disadvantages

- Limited I/O capacity

- Not suitable for complex applications

- Can be slow

4. What are the different types of sensors used in automation systems, and what are their applications?

- Position sensors: These sensors are used to measure the position of an object. They can be used in applications such as robotics, assembly lines, and packaging.

- Proximity sensors: These sensors are used to detect the presence of an object without physical contact. They can be used in applications such as conveyor systems, automatic doors, and safety systems.

- Temperature sensors: These sensors are used to measure temperature. They can be used in applications such as HVAC systems, industrial processes, and medical devices.

- Pressure sensors: These sensors are used to measure pressure. They can be used in applications such as hydraulic systems, pneumatic systems, and process control.

5. What are the different types of actuators used in automation systems, and what are their applications?

- Electric actuators: These actuators use electric motors to convert electrical energy into mechanical motion. They can be used in applications such as robotics, assembly lines, and packaging.

- Hydraulic actuators: These actuators use hydraulic fluid to convert hydraulic energy into mechanical motion. They are typically used in applications where high force and speed are required, such as construction equipment and industrial machinery.

- Pneumatic actuators: These actuators use compressed air to convert pneumatic energy into mechanical motion. They are typically used in applications where high speed and precision are required, such as medical devices and textile machinery.

6. What are the different types of communication protocols used in automation systems?

- Industrial Ethernet: This is a set of networking protocols used in industrial automation systems. It provides high-speed data transfer and is widely used in manufacturing and process control.

- Fieldbus: This is a family of communication protocols used in industrial automation systems. It is designed for low-speed data transfer and is commonly used in distributed control systems.

- Modbus: This is a serial communication protocol used in industrial automation systems. It is widely used for communication between PLCs and other devices.

7. What are the different types of software used in automation systems?

- PLC programming software: This software is used to create and modify PLC programs. It typically includes features such as ladder logic editors, debugging tools, and simulation capabilities.

- SCADA software: This software is used to monitor and control industrial processes. It typically includes features such as real-time data acquisition, alarm management, and trending.

- MES software: This software is used to manage manufacturing operations. It typically includes features such as production planning, scheduling, and quality control.

8. What are the different standards used in automation systems?

- IEC 61131-3: This is an international standard for PLC programming. It defines a set of programming languages and software tools that can be used to create PLC programs.

- ISA-88: This is an international standard for batch control systems. It defines a set of guidelines for the design, implementation, and operation of batch control systems.

- ISO 9001: This is an international standard for quality management systems. It provides a set of guidelines for organizations to ensure that their products and services meet customer requirements.

9. What are the future trends in automation systems?

- Increased use of artificial intelligence (AI): AI is being used to develop new and innovative automation solutions. For example, AI can be used to optimize production schedules, predict maintenance needs, and detect quality defects.

- Greater connectivity and interoperability: Automation systems are becoming increasingly connected and interoperable. This allows for the integration of different systems and devices, creating more efficient and effective automation solutions.

- More user-friendly interfaces: Automation systems are becoming more user-friendly. This makes it easier for operators to use and maintain the systems, reducing the need for specialized training.

10. What are your strengths and weaknesses as an Automation Engineering Technician?

Strengths

- Proficient in PLC programming, SCADA software, and MES software

- Extensive experience in designing, implementing, and maintaining automation systems

- Strong understanding of electrical and mechanical engineering principles

- Excellent troubleshooting and problem-solving skills

Weaknesses

- Limited experience in AI and machine learning

- Not fluent in all major industrial communication protocols

- Still learning about new industry standards and best practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automation Engineering Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automation Engineering Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automation Engineering Technicians play a crucial role in maintaining and troubleshooting automated systems in various industries. Their responsibilities encompass a wide range of tasks, including:

1. System Installation and Troubleshooting

Installing, configuring, and testing new or upgraded automation systems.

- Diagnosing and repairing system malfunctions, identifying root causes, and implementing corrective actions.

- Performing preventive maintenance tasks to ensure optimal system performance and longevity.

2. System Optimization and Automation

Identifying areas for process improvement and implementing automation solutions to streamline operations.

- Developing and executing test plans to verify system functionality and identify potential vulnerabilities.

- Collaborating with engineers to design and implement custom automation solutions tailored to specific application needs.

3. Technical Support and Training

Providing technical support to internal and external stakeholders, including troubleshooting, user assistance, and documentation.

- Training operators and maintenance personnel on proper system usage, maintenance procedures, and safety protocols.

- Developing training materials and manuals to ensure effective knowledge transfer.

4. Documentation and Compliance

Maintaining accurate and up-to-date system documentation, including schematics, wiring diagrams, and maintenance logs.

- Ensuring compliance with industry regulations and standards, such as OSHA and NFPA.

- Participating in audits and inspections to demonstrate system performance and adherence to best practices.

Interview Tips

To ace an interview for an Automation Engineering Technician role, candidates should consider the following tips:

1. Technical Proficiency

Demonstrate a solid understanding of automation principles, control systems, and electrical engineering concepts.

- Familiarize yourself with common automation software and hardware, such as PLCs, HMIs, and sensors.

- Practice troubleshooting scenarios and be prepared to discuss your problem-solving approach.

2. Analytical and Problem-Solving Skills

Highlight your ability to analyze complex systems, identify root causes, and develop effective solutions.

- Share examples of projects where you successfully diagnosed and resolved technical issues.

- Explain how you prioritize tasks and manage time effectively in a fast-paced environment.

3. Communication and Interpersonal Skills

Effective communication and interpersonal skills are essential for building strong relationships with colleagues and customers.

- Demonstrate your ability to work effectively in a team environment and collaborate with engineers, technicians, and operators.

- Show that you can clearly articulate technical concepts to non-technical stakeholders.

4. Industry Knowledge

Research the company and the specific industry in which they operate.

- Learn about their automation systems, production processes, and safety protocols.

- Show that you are aware of industry trends and best practices.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Automation Engineering Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.